April 2009 Vol. 236 No. 4

Features

Risk-Management Process For Urban Utilities

The distribution of natural gas in an urban utility has inherent risks. Distribution networks are located underground, out of sight and typically under pavement in close proximity to buildings, residences and subsurface structures.

Urban customers in older cities are located in densely populated centers that have piping systems dating back to the 1800s. These facilities vary widely in composition, pressure, age and type. Many factors influence the risk of distributing natural gas in such an environment. Despite the many risks, the natural gas distribution industry has an extremely safe and reliable record of transporting gas to millions of consumers every day.

The industry’s safety record is really a product of the due diligence demonstrated by the utilities that transport the commodity. Since the Pipeline and Hazardous Materials Safety Administration (PHMSA) enacted compliance regulations decades ago (CFR 49 Part 192), utilities have had processes in place to assess the health and safety of their systems. While many of these processes have been in place for many years, utilities are always looking to improve their procedures, and in many cases, go above and beyond the federal and state requirements to create a safe and reliable environment.

Philadelphia Gas Works (PGW) exemplifies one of these utilities that constantly looks for better ways to operate and maintain its systems. PGW began distributing gas in 1836 in the oldest parts of Philadelphia, PA. Through the years, the system has grown to encompass 6,000 miles of gas mains and services under some of the busiest, oldest and most complex streets in the nation. The system is comprised of a laundry list of pipe materials and fittings, with the highest percentage, or more than 1,600 miles, cast iron. Much of this pipe dates back to the late 1800s.

The characteristics of PGW’s distribution system create a daily challenge to the operators to maintain a safe, reliable service to the community. This is a challenge that PGW takes seriously and keeps managers constantly searching for new and innovative ways to improve. This dedication of evolving and improving is evident upon evaluation of PGW’s risk-management process. Risk management, by that name, formally began in the 1980s at PGW and has evolved through the decades into a sophisticated system today.

Historical Perspective

In the 1980s, as its distribution system began to show signs of aging, PGW implemented a formal risk-based process to replace, rehabilitate or remove facilities that posed the highest risk to public safety and its ability to reliably serve its customers. PGW then and now operates predominantly an inches water column pressure gas distribution system.

The system’s operators recognized that the highest risk for an incident was the break of a small-diameter cast iron main whose escaping gas could migrate into a building basement. This type of failure of a cast iron main introduces a significant amount of gas to the environment when compared to a steel corrosion leak and presents a higher safety risk to the public. As a result, PGW began to evaluate its cast iron mains on several factors, including incidents on the city block in which the main is located, age of the main, number of failures of the main, failures of the main’s supporting media, mains within the slope of a parallel excavation, and mains within a crossing excavation.

This type of manual process was effective in providing a focused effort on reducing main breaks and an objective method for comparing one main to another. In the end, PGW used the information gleaned from this method to identify, prioritize, budget and design the replacement of more than 80,000 feet of its small-diameter cast iron main per year in the 1980s and early 1990s.

In the mid 1990s, PGW wanted to improve upon this process in favor of a better way to assess the risk on its system. The goal was to create a qualitative and systematic method to support its assessment of its cast iron main. In 1995, PGW implemented a semi-automated process that relied on data it began to collect in its Block Information & Leak Tracking system (BILT).

The evaluation remained a risk-based approach that focused on small-diameter cast iron incorporating parameters such as main size, break history, leak history, pre-1900 vintage pipe, pipe age and service length (i.e. proximity to buildings), into the risk model. Each main in the system was evaluated and given a risk score based on a weighting scheme assigned to each parameter. The mains were then ranked by their risk score to determine those that should be targeted first for replacement.

Similar to the earlier system, this new automated approach proved to be effective in evaluating the overall risk of the system. However, PGW wanted to know how its risk profile fared against industry peers. The utility was interested in learning if there were any areas that it could improve upon. As a result, in 1999, PGW contracted with an independent consultant to perform a benchmarking study that provided an analysis on how PGW statistically ranked among its peers with respect to risk management.

The end result of the analysis showed that PGW’s distribution system, particularly the cast iron network, performed at or better than its peers. Two key statistical parameters, breaks per mile and PGW’s cast iron replacement rate, were in line with industry standards. The study also affirmed PGW’s focus on preventing cast iron breaks, since its peers agreed that these mains pose the highest risk to distribution systems.

Following the benchmarking study, PGW continued to improve its ranking process by enhancing its program’s capabilities. In the years following the assessment, PGW focused on adding more parameters to the ranking process, attempting to make it as comprehensive as possible. Additional parameters incorporated into the prioritization process included mains with a history of breaks as well as service history.

With a focus on cast iron mains, PGW developed an additional model that related average daily temperature to frost depth. This model predicted main break rates and was used to predict periods of accelerated cast iron main break activity. This allowed PGW to proactively schedule resources to take preventive and mitigative operating measures. In addition to replacing cast iron main, PGW was making a determined effort to remove deteriorating steel services.

Risk Management Today

PGW’s trend, as is underscored by its history, is one of constant evaluation and improvement. In 2008, only nine years after the initial benchmarking study, PGW decided to have another independent consultant review its risk-analysis processes and recommend areas of improvement. Again, the first step was to rank PGW against its peers with respect to risk analysis and mains replacement and repair practices.

Similar to the initial evaluations in 1999, 2002 and 2004, the study compared statistical parameters such as leak rate per mile, percentage of the system replaced each year, number of incidents, service lines replaced, leak causes and replacement and repair methodologies. In the end, the report found that PGW was on a par with its urban peers. But there were still areas in which PGW could improve.

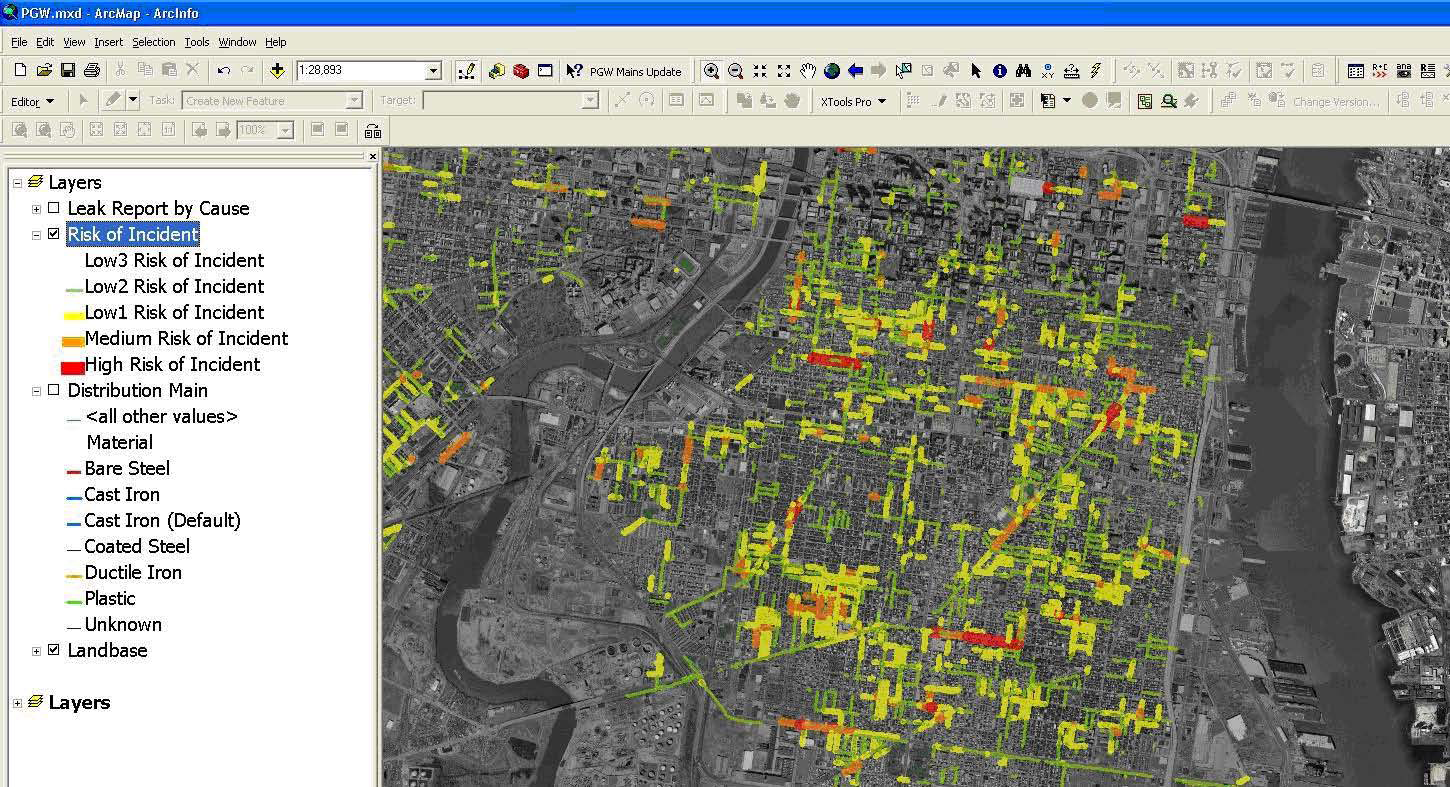

One improvement PGW has made in conjunction with the benchmark analysis study is the implementation of a comprehensive risk-management system that links its mapping systems, the Underground Facilities Database (UFD). This is an updated and enhanced version of BILT. At the core of the new solution is Advantica’s Mains Replacement Prioritization (MRP) product which provides PGW with a scientific methodology for assessing the condition and risk of its metallic mains based on the pipe properties, leak and break history and other factors such as proximity to building, gas ingression and numbers of services.

The initial risk factors are very similar to the previous methodology. However, MRP provides the foundation to expand and enhance those system analysis capabilities. MRP’s open ESRI® ArcGIS™ architecture enables PGW to incorporate information from a variety of additional sources into the risk-and-condition assessment.

These sources now include the PGW leak-management system, its network analysis program (SynerGEE), and the City of Philadelphia’s land base data which includes the street network, waterways, building parcels, railroads, aerial photography, city parks and areas of recreation, and the locations of critical buildings such as hospitals, schools, and municipal buildings. The MRP condition and risk analysis methodology incorporates all of this extended information, and as a result, provides PGW with a relative ranking of each cast iron main in the system.

With all the data feeding into one decision-support system, PGW can make risk-analysis decisions based on a holistic view of the system. None of these decisions are more important than dealing with aging cast iron infrastructure. With more than 1,600 miles of cast iron to manage, having information readily accessible to assess each cast iron main in the system for risk is a critical aspect of PGW’s daily operations.

Once each of the mains in the network is ranked, PGW can determine the best approach for mitigating the main’s risk. Using additional functionality provided by MRP, the software will assemble a set of recommended replacement projects that address the mains that are leading candidates for replacements. This provides PGW with an objective means of quickly evaluating and then commissioning replacement projects that optimize the use of the ratepayers’ money while removing those assets that pose the most public risk.

Planned replacement projects along with risk and condition scores can then be mapped and published from the MRP environment for other key decision makers in PGW to review and provide valuable insight. This provides an avenue for sharing information with other PGW departments, thus enabling them to better understand the system.

Future Improvements

As everyone in the industry has come to appreciate, the distribution integrity regulations will transform the way risk is evaluated on local systems. Fortunately for PGW, it has always taken a proactive approach in trying to learn more about its system and improve its processes. Specifically, over recent history PGW has (1) taken the steps to develop a comprehensive risk-management process that will provide the foundation for complying with the new regulations, and has (2) developed a philosophy of constantly striving to perform better today than it did yesterday. Over the next year, as the industry absorbs and responds to the new regulations, PGW will look for new and improved ways to enhance its risk-management processes.

Authors

Michael Jones has worked for more than 27 years at PGW, much of that time in the Distribution Department’s Planning and Engineering group. As Director, Compliance and Technical Services, he is responsible for field operations and environmentgal compliance with state and federal regulations.

Jeff Meyers is a professional engineer with more than 25 years of experience in the natural gas industry. Seventeen of those years were devoted to work for major distribution companies and the remainder for natural gas engineering firms.

Brett Beaver is a Business Development Manager for Advantica. He manages gas distribution and transmission accounts in North America that are clients of Advantica’s Stoner Software, including MRP. 717-724-1925, Brett.Beaver@advanticagroup.com.

Comments