August 2009 Vol. 236 No. 8

Features

A New Angle On Solving Unpiggable Pipeline Challenges

This is a story of how GE’s SmartLaunch™ system made in-line inspection (ILI) possible in “unpiggable lines” beneath the streets of New York.

Theoretically, any pipeline can be modified to allow in-line inspection. Practically however, the costs of excavations and permanent installations have been, in most cases to date, exceedingly prohibitive. Even where traditional modifications are feasible from engineering and logistics perspectives, flow interruption may not be an option – either because they are critical supply lines or because the associated lost revenues could be nearly insurmountable.

Notwithstanding, prudent pipeline integrity managers know the safety and productivity issues that are at stake over the long term. They are also well aware of the accuracy and planning benefits that high-quality in-line inspection data offer over potentially supply-disrupting alternatives such as hydrostatic testing. Compounding all these pressures is the simple fact that many operators, particularly in the U.S., now face strict regulatory deadlines to assess the integrity of their yet-uninspected pipelines.

So, many pipeline operators and distribution companies are in dire need of ways to proceed with in-line inspections of their “unpiggable” lines. But how–and at what cost?

New York City Autumn 2007

National Grid is one such company seeking an answer. Not yet facing a regulatory deadline, but taking a proactive approach to integrity planning, the company contracted GE Oil & Gas – PII Pipeline Solutions to inspect its two-mile Backbone pipeline running under the busy streets of Brooklyn and under an East River tributary into Queens.

Natural gas flow could not be interrupted for extended periods of time and there were no existing launch or receive traps. Essentially, there were no easy ways into this pipeline. Launch-site excavation had to be conducted near a busy traffic intersection with a population of nearly five million people around. This environment was truly a High Consequence Area and exactly the kind of situation for which SmartLaunch was created.

SmartLaunch

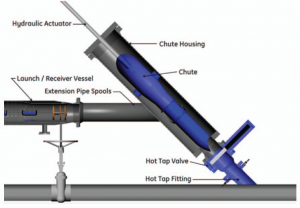

GE’s system, which has a patent pending, utilizes an industry-standard angle hot-tapping process that leaves behind a stopple-type fitting that can be plugged and unplugged to facilitate installation of portable launch and retrieval spools to enable the current in-line inspection project and simplify future re-inspection.

SmartLaunch chute configuration.

To provide a manageable access point in restrictive environments (as was the case in Brooklyn and Queens), SmartLaunch’s chute housings are installed temporarily to 45° angle split-tee fittings at both the launch and receive sites. Each housing incorporates a retractable chute that is hydraulically inserted through the angled fitting to ensure clean, safe passage of the ILI tools into and out of the operating pipeline. The equipment is configured to enable the use of conventional launchers and receivers as well as standard kicker pipe work to initiate inspection.

Designed for the most challenging settings, the SmartLaunch configuration requires that some very tight radius bends be navigated – including a 1D bend that cannot be passed by traditional ILI tools.

Therefore, the system’s companion SmartScan™ tool is employed–a multi-diameter MFL inspection technology introduced in 2004. The 20- 26-inch SmartScan tool used on this project was accompanied by multi-diameter cleaning and caliper tools designed to share a common tow section for optimized efficiency.

From Plan To Action

There can be nothing quick or simple about an operation of this type. Environmental and community safety, and uninterrupted flow are of paramount importance.

Launch (top) and receive (bottom) sites were located in a High Consequence Area surrounded by busy auto traffic and densely populated residential and business districts.

The overall project required two separate mobilizations. The first involved the hot tapping operation, which kicked off in Oct. 2007. National Grid’s crews began coordinating with state and city regulatory officials to manage excavation of the launch and receive sites. The crews did an exceptional job of mitigating logistical challenges associated with the proximal, dense residential areas. GE contracted with a third party to complete the six day hot tapping program, which included kicker piping access points. The second mobilization began in the spring of 2008 with four flatbed trucks delivering launch and receive equipment to National Grid’s workshop where crews began assembly of the complex interconnect piping.

Inspection Profile

The 24-inch Backbone pipeline’s normal operating pressure of 276 psi (19 bar) had to be sustained for extended periods to ensure the flow rate necessary for inline inspection. The client met this challenge by coordinating with gas control to secure adequate upstream supply and to control downstream demand. The line included numerous 1.5D bends, 22° mitre joints. It had been in operation since the early 1950s and had never been cleaned and inspected by an ILI tool.

Since this was a critical line and its internal condition was unknown, blockage risks were mitigated through an intensive cleaning regimen involving a series of runs by poly pigs, customized multi-diameter cleaning pigs and magnetizer cleaning pigs. Only when clear passage was certain, could the multi-diameter caliper and SmartScan tools be launched.

The metal loss and geometry inspections were completed successfully with no speed excursions or tool damage – and an excellent data set was acquired.

Conclusion

While SmartLaunch and SmartScan are designed to minimize labor and engineering time required for addressing unpiggable pipeline challenges, every project of this type must still be treated as a unique situation. The intrinsic physical limitations are always greatly compounded by the reality of unique site surroundings, multiple regulatory approval levels, safety considerations and zoning requirements. Pre-inspection planning, tight project management and a close client-crew working relationship are all crucial to success.

PII’s crews have performed in-line inspections in every operating environment worldwide for more than 40 years. But this project was clearly one of the most demanding ever undertaken. As such, a number of valuable lessons were learned, with subsequent process and design improvements that will significantly benefit future inspections for all our customers. For example, we have increased the efficiency of in-field equipment delivery procedures, designed layout improvements to minimize field welds to kicker, and gained even greater insights about the operational challenges that our customers face during the inspection process.

Post-inspection SmartScan tool.

SmartLaunch will not be cost effective everywhere – it was designed for extraordinary circumstances. When both the stakes and obstacles are high, its unique combination of technologies and procedures will deliver the pipeline integrity knowledge needed to ensure long-term, reliable product supply.

Project cycle

Pre-inspection

1. Site survey.

2. Design and manufacturing

of 45° tee and kicker piping.

3. Excavation.

4. Quality assurance of tee

welding procedures.

5. In-service tee welding.

6. Hot tap installation.

7. Launch equipment and

kicker pipe rigging.

In-line

8. Cleaning.

9. Filtration.

10. Waste disposal.

11. Caliper inspection.

12. SmartScan inspection.

Completion

13. Launch and receive

equipment removal.

14. Plug completion.

Acknowledgement

The author expresses sincere thanks to National Grid for their tremendous partnership on this project and for their kind permission to tell the story.

The author

James Walker is the marketing manager responsible for global product marketing of GE’s portfolio of pipeline inspection services and is based in Houston. He is also the contact liaison for engagement with industry groups such as PRCI and INGAA. He joined GE Oil & Gas in 2003 as a strategic marketing manager for pipeline integrity services and then moved to a field services product management position in 2007. During his tenure, the field services business has grown significantly, particularly in the unpiggable projects sector. He holds a bachelor of science degree in business and a master of business administration degree, both from Colorado State University.

Comments