December 2009 Vol. 236 No. 12

What's New

December New Products

New product offerings from Lincoln Electric, Caterpillar, E.H. Wachs, BJB Company, Veris Inc., ESAB Welding & Cutting Products, Phoenix Contact, R&M Energy Systems, CygNet Software, Stream-Flo Industries, PFERD Inc., GE Oil & Gas PII Pipeline Solutions, Darby Equipment, Exterran Holdings Inc., McElroy Manufacturing and Midwest Pipeline Rehabilitation.

Lincoln Electric

Lincoln Electric has added the new Ranger® 225 to its engine-driven welder product portfolio. This rugged welder/generator delivers smooth DC welding output and 10,500 watts peak AC generator power. It is ideal for construction contractors, maintenance crews, farmers and ranchers. It features a fully enclosed case that protects and helps to lower noise levels when compared to a partially enclosed or unenclosed welder of comparable size and output. Engine service is achieved with three sizable engine access doors. This engine-driven welder handles a variety of basic welding jobs with 225 amp/25 volt welding output for stick, TIG, MIG and flux-cored arc welding, as well as arc gouging. Its smooth DC welding output is designed for a broad range of stick electrodes, including Lincoln’s Excalibur® 7018 (AWS E7018) and Fleetweld® 5P+ (AWS E6010). 888-355-3213, www.lincolnelectric.com, Bulletin E6.89.

Caterpillar

Caterpillar offers an electronic brochure devoted to its new Cat® D7E with electric drive. It is a mid-size track-type tractor powered by what is termed a revolutionary AC electric drive system. Cat says the unit delivers powerful dozing and precise maneuverability while burning less fuel and reducing lifetime owning and operating costs. The unit’s Cat C9.3 ACERT™ engine turns an electric generator that converts mechanical energy into AC electrical current. The current flows through armored cables and military-grade connectors to a solid-state power inverter. The propulsion module delivers well-modulated torque via axles to the final drives. These consist of state-of-the art AC electric motors. The propulsion module has no moving electric contacts and few moving mechanical parts. There are no engine belts to repair or replace. www.cat.com/D7E.

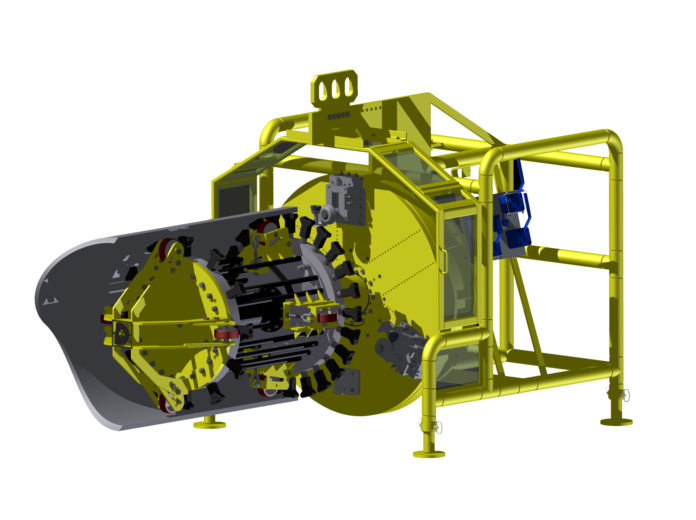

E.H. Wachs

E.H. Wachs has published a flyer focusing on its combination ROV-attended prep tool for subsea pipelines. The Combination Prep Tool is able to sever, bevel (inside and outside) and remove FBE and the weld seam on pipe in diameters from 12-24 inches. The Wachs Combination Prep Tool is comprised of major modules that include the Universal Tool Platform, Severing /OD Bevel Module, FBE Removal Module, Weld Seam Removal Module and Deployment Frame. The machine weighs 5,125 pounds dry and 40 pounds in sea water (250 pounds of ballast added). 800-323-8185, www.ehwachs.com.

BJB Company

BJB Company has published a pocket flyer to introduce its experience and services. In a section, “What we can do for you,” the company says it has constructed more than 1,700 miles of pipeline over the years ranging in diameter from 4-42 inches. Its personnel also have the experience and equipment to perform such tasks as leak repair, re-routing, lowering, coating and repairs, road bores, clock spring installation, trunk lines, refineries, right-of-way maintenance, cathodic protection system installation and hydostatic testing. The company says in construction and maintenance it is flexible enough to handle subcontract work all the way to full turn-key EPC or alliance agreement work. It offers on-site nitrogen generation and supply services. 432-683-7074, info@bjbinc.com.

Veris, Inc.

Veris offers a brochure devoted to the Veris Verabar® advanced DP flow measurement technology for gas, liquids and steam. The Verabar averaging flow sensor was developed from aerospace technology and provides unsurpassed accuracy and reliability. It is of solid, one-piece construction and has a bullet shape designed to make its flow measurement clog-free and precise. The unique sensor shape reduces draft and flow-induced vibration. The location of the low-pressure ports eliminates potential for clogging and improves signal stability. The design is said to offer a unique and exclusive breakthrough in improved accuracy derived from the development of a verified theoretical model that predicts the Verabar flow coefficients. This eliminates the need for calibration tests to characterize the flow coefficients. Ginny Kyle, 303-652-8550, www.veris-inc.com.

Cameron Compressor Systems

Cameron Compressor Systems says power parts are available now. The company reports that its Ponca City, OK facility has a strong supply chain for Clark®, Ingersoll-Rand® and Worthington® power parts. Cameron says the facility, formerly Nickles Industrial Manufacturing, is the company’s center-of-excellence for new manufacturing, repair, unit exchange and remanufacturing of large-bore engine power parts. 800-654-6419, rodger.geurin@c-a-m.com, www.c-a-m.com/cs.

ESAB Welding & Cutting Products

ESAB Welding & Cutting Products recently introduced two Caddy™ Arc welding power supplies. The Caddy™ Arc 151i and 201i single-phase DC/CC power supplies are designed primarily for SMAW (Stick) and feature an adjustable arc force that sets the intensity of the arc to ensure weld quality. Other features include an adjustable hot start that makes it easy to strike the electrode and avoid starting problems and ESAB’s ArcPlus II feature that controls the arc to improve welding characteristics, simplify use, produce better quality welds and reduce clean up. This fifth-generation of Caddy machines features advanced inverter technology to deliver the highest welding quality. 800-ESAB-123, www.esabna.com.

Phoenix Contact

Phoenix Contact has introduced the PC 35, a pluggable PCB terminal block that can carry up to 115 amps. The connector is said to have the highest current-carrying capacity on the market. It features standard screw-connection technology and accepts wires up to 2 AWG. It is UL-rated for field wire termination, which is accomplished with a screwdriver. Through-panel mount capability increases design flexibility. The contact design creates low insertion and withdrawal forces. These light-touch forces reduce mechanical stresses and possible damage to the PCB solder joints. The silver-plated contacts are highly conductive and provide long-term reliability. The 600-volt UL and 1,000-V IEC ratings meet international requirements. Optional shielding is available for applications that may be exposed to electro-magnetic interference. 800-322-3225, info@phoenixcon.com, www.phoenixcontact.com.

R&M Energy Systems

R&M Energy Systems offers its latest, most technically advanced solution for pipeline and vessel closures. Marketed under the SENTRY® brand name, this non-threaded, internal door closure now features an innovative one-piece seal. The one-piece seal is molded in all sizes with no vulcanized splices, is available in FKM (Viton), EDR FKM (Viton), NBR, or HNBR low-temperature materials (other compounds are available upon request), and features an anti-extrusion spring molded directly into the seal for easy installation and to ensure secure sealing. Installation of the one-piece replacement seal is quicker than ever, resulting in reduced maintenance time and lower incurred maintenance costs. All pressure-retaining components on the closure are manufactured from ASME SA-designated materials. An improved hinge arrangement and a unique means of holding the locking segments in the open position make operation smooth and easy. 936-890-1064, 403-264-2995, info@rmenergy.com, www.rmenergy.com.

CygNet Software

CygNet Software has announced CygNet for Pipeline™, describing it as the oil and gas pipeline industry’s first packaged vertical solution for pipeline operators. The company said it was designed to dramatically reduce the risk, time and cost required for enterprise operations software projects. It includes segment-specific implementation templates, device connectors and applications for standardized gas operations functionality and is said to enable companies to rapidly install and begin using the CygNet Enterprise Operations Platform (EOP) within a matter of weeks rather than years. According to Darin Molone of Atlas Pipeline, “With CygNet, Atlas was up and effectively functioning with a new enterprise SCADA solution in about three weeks. Plus, I can tune the system myself as often as I want, typically without needing to involve our IT team.” 888-781-3580, http://cygnetscada.com/.

Stream-Flo Industries

Stream-Flo Industries, the manufacturer of Crown-Judd Check Valves, has added a new product to its full line of API-6D check valves. The Crown-Europa Nozzle Check is a Non-Slam Axial Flow Piston Check in sizes from 2-60 inches and ANSI classes 150-2500. The Crown-Europa Nozzle Check is said to exhibit very quick “non-slam” closure while delivering extremely low pressure drop across the valve, resulting in significant fuel savings in critical compressor and pump discharge applications. 832-912-1022, info@streamflo.com, www.streamflo.com/check-valves/.

Dresser Waukesha

Dresser Waukesha, manufacturer of natural gas engines that deliver clean, cost-effective power, has introduced the 12-cylinder 12V275GL engine, the latest in Dresser Waukesha’s 275GL™ Series, a new generation of high-performance engines for gas compression applications. The new engine is rated at 3,375 bhp at 1,000 rpm. That is 8% greater than its predecessor, the 12-cylinder ATGL®. With design and engineering updates as well as an enhanced engine control system, the new engine is designed to maximize efficiency and minimize fuel costs while simplifying and improving packaging, operation and service. Standard on 275GL Series engines is an enhanced version of Waukesha’s reliable, easy-to-use total engine control system, the Engine System Manager (ESM®). ESM optimizes engine performance and maximizes uptime by integrating spark timing control, turbocharger control, speed governing, knock detection, start-stop control, diagnostic tools, fault logging, engine safeties and air/fuel ratio (AFR) control. www.dresser.com/waukesha, http://www.dresserwaukesha.com/documents/1426.pdf.

PFERD, Inc.

PFERD Inc. says all the work-saving features of its radically designed Polifan® Curve flap disc are covered in a new product literature sheet. Features include a unique radial shape and abrasive flaps layered around the edge that continue to the top of the disc for grinding under edges or blind spots. Color photographs along with operating advantages, work benefits, application recommendations, dimensions, material specifications and ordering instructions are provided in the product literature. 800-342-9015, solutions@pferdusa.com, www.pferdusa.com.

E.H. Wachs

E.H. Wachs has launched the new EP 424 End Prep Machine Tool. The company says along with the new speed prep feed system is a precision ID mount end prep machine tool designed to bevel, compound bevel, J prep, face and counterbore pipe, fittings and valves. Utilizing what the company terms a revolutionary new mechanism that feeds simultaneously in the axial and radial planes, the tool is able to machine any bevel or compound bevel without templates, incline tool slides or work stoppage. 847-537-8800, www.ehwachs.com.

GE Oil & Gas PII Pipeline Solutions

The new PipeView™ BandGen is described as a powerful extension that gives pipeline operators practical tools for creating, configuring, manipulating and generating bands for custom alignment sheets. It extends the capabilities of ESRI’s ArcGIS 9.3 system by adding powerful tools for managing bands, validating sheet content and placing alignment sheets. Alignment sheet appearance is easily configured with out-of-the-box tools directly from the familiar ArcMap table of contents. Ad hoc sheets can be created using the current extents of the ArcGIS viewing window and, in the event of an error, source data can be dynamically edited from the band. GE says BandGen is flexible, works independently of data models, and can support multiple source formats and locations. www.geoilandgas.com/pii.

Comments