March 2010 Vol. 237 No. 3

Features

Corrosion Control In Oil And Gas Pipelines

In the United States, the annual cost associated with corrosion damage of structural components is greater than the combined annual cost of natural disasters, including hurricanes, storms, floods, fires and earthquakes(1). Similar findings have been made by studies conducted in the United Kingdom, Germany, and Japan.

According to the U.S. Department of Transportation Office of Pipeline Safety, internal corrosion caused approximately 15% of all reportable incidents affecting gas transmission pipelines over the past several years, leading to an average cost of $3 million annually in property damage, as well as several fatalities. The need to manage and mitigate corrosion damage has rapidly increased as materials are placed in more extreme environments and pushed beyond their original design life.

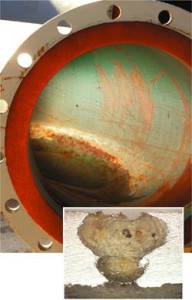

Typical corrosion mechanisms include uniform corrosion, stress corrosion cracking, and pitting corrosion (Figure 1). Corrosion damage and failure are not always considered in the design and construction of many engineered systems. Even if corrosion is considered, unanticipated changes in the environment in which the structure operates can result in unexpected corrosion damage. Moreover, combined effects of corrosion and mechanical damage, and environmentally assisted material damage can result in unexpected failures due to the reduced load carrying capacity of the structure.

Figure 1: Localized corrosion in process piping, such as in the stainless steel pipe shown here, can lead to through-wall penetration (inset).

Ensuring long-term, cost-effective system integrity requires an integrated approach based on the use of inspection, monitoring, mitigation, forensic evaluation, and prediction. Inspections and monitoring using sensors can provide valuable information regarding past and present exposure conditions but, in general, they do not directly predict remaining life. Carefully validated computer models, on the other hand, can predict remaining life; however, their accuracy is highly dependent on the quality of the computer model and associated inputs. Mitigation (corrosion prevention) methods and forensic evaluations play a key role in materials selection, assessment and design. All of these corrosion-control elements represent long-standing areas of research and development at Southwest Research Institute® (SwRI®).

Pipeline Inspection

A significant portion of many pipeline systems cannot be inspected through traditional methods. Nondestructive evaluation (NDE) and inspection tools are critical to assessing the integrity of pipelines. Traditional NDE methods involve the use of pipeline inspection gauges (PIGs), which travel through the inside of a pipe and detect the presence of mechanical damage or corrosion.

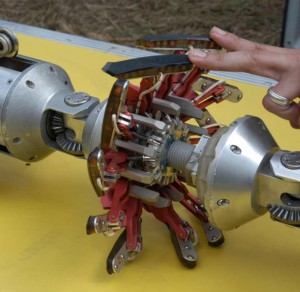

Researchers at SwRI have developed an inspection system for inspecting pipelines that cannot accommodate traditional PIGs (Figure 2). This system uses remote field eddy current (RFEC), and was designed for use with the Carnegie Mellon Explorer II Robot. However, this technology can be adapted to other transport mechanisms. The system can expand to inspect 6-8 inch (150-200 mm) diameter lines. The sensor arms retract to accommodate line restrictions, such as elbows, tees and gate valves.

Figure 2. RFEC system for inspection of unpiggable pipelines.

SwRI has also developed a guided-wave inspection technology that can be used to inspect pipelines and other structural components such as tubes, rods, cables and plates. The Magnetostrictive Sensor (MsS) inspection system uses inexpensive ribbon cables and thin magnetostrictive strips that are bonded to the component for inspection. The sensors attached to the pipe can accommodate a range of pipeline diameters, which is a significant advantage of guided-wave inspection systems that use an array of piezoelectric sensors. Because the sensors are low profile and relatively low cost, permanent installation of the sensors to perform structural health monitoring is a practical option.

Corrosion Fatigue

Corrosion can degrade the mechanical integrity of a material through chemical attack. For example, the presence of hydrogen sulfide (H2S) has been found to reduce the fatigue life of offshore riser materials by approximately a factor of 10, and in the presence of a notch (that acts as an initiation point for corrosion fatigue) the fatigue performance can be decreased by a factor of 100. SwRI has developed customized test facilities for characterizing the performance of pipeline materials in corrosive environments. Figure 3a shows a servohydraulic load frame setup with a custom-designed test cell and redundant H2S containment systems. Full-thickness fatigue specimens (Figure 3b) are machined from riser pipes to preserve through-thickness residual stresses and to capture welds in joined pipe.

SwRI recently developed a high pressure, high temperature (HPHT) corrosion fatigue test facility. In this facility the underlying fatigue crack growth behavior of riser materials subject to HPHT H2S (and other aggressive) environments can be quantified (Figure 3c). This unique test facility provides the capability to quantify inter-related corrosion-fatigue mechanisms, and provide data for calibrating and validating corrosion-fatigue computer models.

Figure 3: a) Servohydraulic load frame with H2S corrosion fatigue test; b) One-meter-long specimen; c) high-pressure high-temperature corrosion fatigue test.

Corrosion Exposure Testing

As new materials are developed and environmental conditions change, assessing material performance due to corrosion and stress corrosion cracking is of increasing importance. SwRI has a well-established corrosion testing facility to perform HPHT testing in extremely aggressive environments. In most cases, the testing environment consists of a simulated process or reasonable worst-case scenario. These include determining the effects of H2S, CO2, oxygen, and microbiological organisms on corrosion/cracking of pipeline materials. Testing conforms to NACE, ASTM, API, or ISO standards and test materials are analyzed for mass loss, localized corrosion or stress corrosion cracking (SSC)/sulfide stress cracking (SSC).

SwRI staffers are highly experienced in designing, constructing and operating specialty tests to mimic a specific operation that does not conform to standardized methods. One such capability is performing the environmental exposure on the API 16C – Flexible Choke and Kill Systems, which evaluates the effects of gas permeation, gas decompression and test fluid exposure at the rated temperature (Figure 4).

Figure 4: Photograph of the API 16C – Flexible Choke and Kill line testing.

Corrosion Prediction

Computer modeling is useful to help understand the mechanisms of internal corrosion, external corrosion and stress corrosion cracking, and to predict corrosion damage, failure and the most likely location of corrosion in oil and gas pipelines. These predictions can help support the development of practical guidelines to assist the pipeline industry in mitigating existing, or preventing future, corrosion failures.

[inline:corr5.JPG]

Figure 5: Tiered modeling approach.

A four-step, tiered approach (Figure 5) is used by SwRI. The first step is to develop comprehensive fundamental models, which forms the foundation of the approach. Validation of the model against field and laboratory data is performed in the second step to ensure the correct physics are embedded in the model. To simplify use of the model in practical applications, the third step is to develop simplified models. During this step, rate-controlling variables or groups of variables are identified. These simplified models contain only the necessary physics and the values of the corresponding inputs to predict the performance of the system. The end goal of the overall modeling approach is step 4, development of guidelines for practical applications of the model. The tiered modeling approach has been successfully used for several recent applications:

- Predicting corrosion in coating disbonded regions with and without the effect of flow.

- Development of the dry gas internal corrosion direct assessment (ICDA) standard, NACE SP 0206-2006.

- Prediction of the most probable corrosion locations in a long underground pipeline due to variability in elevation, flow characteristics and materials.

- Prediction of the most likely conditions for internal corrosion due to variability in operations, gas quality upsets, and water intrusions.

Corrosion Sensing And Monitoring

While ICDA models can provide general guidelines to identify when internal inspections should occur, environmental and material uncertainties can lead to situations where excavation is performed unnecessarily, or water exists but is not predicted. In either case, costs associated with inspection or failure can be significant. To address this, sensing and monitoring technologies have been developed to enable remote interrogation of the internal corrosion of pipelines.

The wireless mobile sensor, shown in Figure 6, travels inside a gas pipeline detecting the presence of water. The system communicates through a distributed wireless sensor network. The sensor body is an injection-molded polymer designed to survive high hydrostatic forces and impact on the pipeline walls while traveling along the pipe. This program has evolved using internal IR&D funding from both SwRI and Aginova, Inc.

[inline:corr6a.JPG] [inline:corr6b.JPG] [inline:corr6c.JPG]

Figure 6: a) Wireless mobile sensor for detection of water within pipelines. b) View of sensor internals including microprocessor and radio modules. c) First-generation sensor prior to use in a pipeline.

The multielectrode array sensor (MAS) probe is ideally suited for monitoring corrosion rates in process streams. Multiple discrete elements or electrodes are used to replicate the material of interest. The MAS probe measures corrosion rates by assessing the current flow between coupled electrodes. The electrodes can be manufactured from a wide range of alloys and product forms. SwRI has used this method to monitor the corrosion of a variety of materials.

The wireless mobile sensor and the MAS probe sensor are just two examples of corrosion sensing and monitoring technologies. SwRI has developed a suite of corrosion sensing and monitoring devices. Significant inspection and repair costs can be avoided with the use of tools such as these.

Deposition Coatings

The deposition of material coatings can be effectively employed to protect surfaces of components from wear, erosion and corrosion. A variety of coatings have been studied including metals, ceramics and polymers. A number of deposition techniques have also been developed. One example is magnetron sputtering, where 20-30 µm thick Al-Ce-Co coatings are deposited on Al alloys and 1018 carbon steel, which is sufficient for most applications where corrosion and erosion are possible. A cross-section Al clad and Al-Ce-Co deposition coating is shown in Figure 7a and 7b, respectively. Microstructural analyses show that under certain deposition conditions, amorphous/nano-crystalline structures are obtained, which show superior corrosion resistance in electrochemical tests.

[inline:corr7.JPG]

Figure 7. SEM cross-section of (a) Al clad and (b) amorphous AlCoCe coating

Diamond-like carbon (DLC) coatings can be produced using the plasma immersion ion deposition (PIID) process. The coatings are very hard and dense and can be applied to many components for increased wear and erosion resistance. In fact, SwRI recently developed a technique for applying DLC coatings to the inner surface of pipeline segments.

Ti-Si-C-N based nanocomposite coatings deposited using the Plasma Enhanced Magnetron Sputtering (PEMS) process have shown high-hardness (>40GPa) and superior erosion and wear resistance. PEMS was originally developed for use on gas turbine compressor blades and vanes and steam turbine blades against solid particle erosion and liquid droplet erosion, and won an R&D 100 award in 2009.

Laboratory tests have shown that the erosion resistance of these coatings can increase the lifetime by a few to more than 100 times as compared to uncoated substrates. The corrosion resistance for Ti-Si-C-N coated samples has been shown to be comparable to or better than the uncoated Ti-6Al-4V substrate, which already exhibits excellent corrosion resistance.

SwRI has developed a suite of deposition-coating solutions for addressing a range of erosion, corrosion and wear issues. As noted, large-scale production of corrosion-resistant coatings using vacuum deposition techniques is possible (e.g. Al-Co-Ce coatings and DLC coatings). For more severe environments, vacuum-deposited Ti-Si-C-N nanocomposite coatings have been successfully used to protect important components from erosion, abrasion and corrosion damage.

Forensic Evaluations

Although a comprehensive corrosion-control program based on inspection, monitoring and model predictions can be an effective means for controlling pipeline corrosion, unexpected events or undocumented changes in operating conditions can still lead to premature pipeline failure. When these occur, it is essential to perform a thorough forensic evaluation of the failure to determine the failure mechanism and its root cause. By identifying the root cause of the failure, the pipeline operator will know if this resulted from an event or operating condition outside of the general conditions included in the corrosion-control program.

Steps can then be identified to mitigate future failures by eliminating recurrence of the event. If such an event is not identified as the root cause of failure, the results of the evaluation can be instrumental in identifying necessary changes to the corrosion-control program. Additionally, destructive evaluations, which are a routine part of a forensic evaluation, can be a valuable tool for validating the effectiveness of a corrosion-control program.

Summary

Aging infrastructure, increasing performance requirements, cost and safety are all driving the need for more comprehensive corrosion control. Experimental assessments of materials in extreme environments will always play a critical role in supporting material selection and design. More recently, the role of computer modeling is playing a more prominent role. As our understanding of the fundamental mechanisms of environmental effects on materials improves, our ability to model these fundamental mechanisms and predict the integrity of complex structures and systems has grown.

These models, however, require information regarding initial conditions, operational conditions, calibration and, most importantly, validation of the predictions. Inspection tools, sensors, and monitoring systems provide key information, but they cannot alone provide estimates of future performance. By coupling inspection, monitoring, mitigation, forensic evaluation, and prediction, a comprehensive corrosion-control program can be realized. Subsequent remedial actions can then be devised to counteract the effects of corrosion, thereby helping to assure the integrity of aging systems.

Acknowledgements

The authors acknowledge the research collaborations and technical support of SwRI staff members Dr. Stephen Hudak (Material and Component Integrity), Dr. Hegeon Kwun and Gary Burkhardt (Staff Scientists, Sensor Systems and Non-destructive Evaluation), Dr. Ronghua Wei (Surface Engineering and Materials Chemistry), Drs. Marta Jakab and Gustavo Vasquez (Environmental Performance of Materials), and Steven Clay (Environmental Performance of Materials). The authors also acknowledge the contributions of Dr. Ashok Sabata, Aginova Inc.

References

1. G.H. Koch; Brongers, M.P.H.; Thompson, N.G.; Virmani, Y.P.; and Payer, J.H., “Corrosion Costs and Preventive Strategies in the United States,” FWHA-RD-01-156, U.S. Department of Transportation, Federal Highway Administration (2002).

Comments