April 2011 Vol. 238 No. 4

Features

Effective Leak Management In Gas Distribution Utilities

There is a growing need for availability of accurate data for gas distribution utilities to help devise programs that maintain and operate pipeline assets. For example, distribution integrity management program (DIMP) regulations require gas distribution utilities in the United States to be able to 1) know the risks in their system, 2) identify various threats in the system, and 3) be able to mitigate the same. Having an effective pipeline leak management process along with supporting IT systems will help cater to the regulatory requirements and also maintain a safe and reliable gas distribution system.

This article is structured to discuss some of the key business processes and IT systems that help collect, analyze and report data. The article discusses: 1) entities that form the leak ecosystem within a gas distribution utility, 2) examples of proactive leak maintenance, 3) different systems that help capture and analyze the data to devise a proactive maintenance plan, 4) sample functional implementation architecture highlighting the functions and communication among these systems, and 5) sample classification of the leak management process maturity. This classification can help gas utilities to identify and focus on areas of improvement.

Leak Ecosystem

In a gas distribution utility, the key entities that form the pipeline leak ecosystem are customer, operator and regulator. Each has an important and responsible role to play in order to ensure that the community has a safe and reliable gas distribution system. As shown in the Figure 1, there are multiple events occurring in the ecosystem that necessitate an interaction and transfer of data among customer, operator and regulator.

Proactive Leak Maintenance

Items of note involved in proactive leak maintenance:

- Leak Classification;

- Survey leaks – Leaks that are identified through a process of proactively surveying the distribution pipeline network for leaks on a periodic basis. The leak survey frequency and subsequent leak repair schedule can be driven by the compliance rules mandated by regulator.

- Emergency leaks – Leaks due to damages that require an immediate attention leading to pipeline repair to neutralize the leak. Damages can be minimized by adopting damage prevention activities such as accurate locates and obtaining permits. Having damage prevention specialists to check on underground projects to make sure proper procedures are being followed also helps prevent damages.

- Sample proactive maintenance – Proactive maintenance includes activities such as taking observations and readings of the distribution pipeline from the field; plotting leaks on a GIS-based mapping system; identifying leak causes. This information can help in taking appropriate action ahead of time to prevent a potential hazard. For example: Aldehyde plastic becomes brittle over a period of time; having the material information will help to identify the cause of leaks and prepare an action to replace the segment with a different material. Capturing pipe-to-soil readings on metal pipe will help identify areas where the cathodic protection needs to be addressed. Similarly, capturing the leak cause will help in devising necessary training if the leak is due to an employee not following proper procedure. Capturing data associated with leak-repair methods employed to repair leaks will help determine if a pipeline segment needs to be replaced; for example, if there are too many clamps on a pipeline segment, it may be worth replacing it.

It is obvious from the examples that, with proper usage of data, gas utilities can determine and implement a proactive action plan to prevent a potential hazard. However, the key is availability of relevant data to help take such decisions. Gas utilities need to deploy business processes and IT systems to help capture data at different levels.

Business Processes And IT Systems

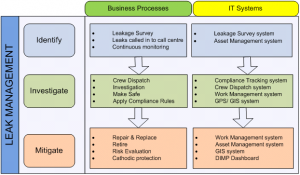

Leak management can be described as a three step process: Identify –> Investigate –> Mitigate. There are different business processes that make up each of these steps. The table shown in Figure 2 maps the different business processes that are part of leak management and relevant IT systems that can help automate the business processes.

Figure 2: Mapping of Business Processes and IT systems.

Typical Functional Architecture

There is no single system that can – on its own – totally help in managing the leaks. Utilities would have to look at a combination of systems that integrate with one another to provide and process data. Figure 3 depicts typical functional architecture that can be considered for this implementation.

Figure 3: Sample Functional Architecture.

Table 1: IT systems and description.

Leak Management Maturity

Gas utilities that have not actively implemented systems automation and are handling the processes manually will find that, with DIMP regulation, there will be a need to gather and process data in abundance.

Figure 4: Leak Management Maturity depiction.

This article has tried to build a sample guide that can be adopted to move up the process maturity of pipeline leak management. Figure 4 classifies the maturity into multiple levels – Level 0 through Level 5. Level 0 indicates that the gas utility has deployed none or minimal automation and most of the business processes are through manual transactions. Level 5 indicates the highest level of maturity wherein the gas utility has implemented various systems and is successfully able to process data for DIMP reporting and other regulatory needs through automation.

Authors

Dean Kelley is a senior business analyst with AGL Resources, Atlanta, GA. He has 33 years of experience in gas distribution operations. In his current role he ensures that the company’s Field Operation and IT Systems work together. He also helps test system updates and changes and responds to production problems. He can be reached at dkelley@aglresources.com.

Surya Chavali is lead consultant with Infosys Technologies Limited, Atlanta. He has 11 years of experience in IT consulting, primarily with U.S. gas and electric utilities. He has performed in different roles as solution architect, functional consultant and project manager. He can be reached at: suryas_chavali@infosys.com.

Comments