July 2011, Vol. 238 No. 7

Features

Four-Tube Coriolis Meter Measures Pipeline Flow Accurately

Until recently, flow measurements in pipeline sizes above 12-inch diameter were usually done with conventional measurement principles, mostly following Bernoulli’s pressure difference principle or mechanical devices that were moved by the media and the number of movements being counted.

Coriolis flowmeters have begun making inroads into pipeline custody transfer flow measurements, mainly because they are the most accurate of all flowmeters. However, Coriolis meters have been limited by size, and in some cases, were perceived as suffering from problems caused by pipeline noise and vibration.

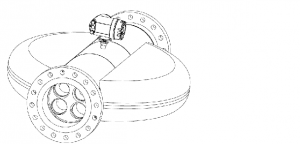

Endress+Hauser developed the first four-tube Coriolis flowmeter to address the problems of measuring flow in large pipelines and presented it at the May 2011 Offshore Technology Conference in Houston. The 14-inch diameter Promass X flowmeter (Figure 1) is designed to measure the mass flow, density and temperature of oil, gas and other fluids in large pipes at rates up to 4,100 metric t/h (4,520 U.S. tons/hr) with extreme accuracy and precision. Long-time measurements on an accredited calibration rig show a rock-stable measurement over time with repeatability of 0.05%.

See Figure 1: The Promass X is the world’s first four-tube Coriolis flowmeter. It was designed to make extremely accurate measurements of liquids and gases in large pipelines.

Expensive Problems In Pipeline Measurements

While being on the market for quite some time, conventional flow instrumentation still has severe drawbacks:

• Low accuracy,

• Low turndown ratio,

• High wear and tear,

• High maintenance costs due to abrasion, adhesion and contamination,

• Sensitivity to flow regime (need for inlet and outlet runs or flow rectifiers),

• Permanent pressure loss,

• Need for mechanical adaptation to changing flow conditions (small window of operation),

• Bulkiness,

• Need for additional mechanical support, and

• Low response time.

Even with a more modern measuring principle, such as ultrasonic flow measurement, the accuracy for flow measurement typically is around ±1%.

A 1% error in flow measurement can be very expensive during custody transfer, where one party is delivering a valuable product, such as crude oil. For example, 4,520 tons of crude oil per hour sum up to about 700,000-750,000 barrels per day. Given the actual prices for crude oil, the value of what is passing through the pipe every hour easily exceeds $3 million. Using a flow measurement device with an accuracy of ±1% means the uncertainty in money equals more than $30,000 per hour. With a flowmeter that has 0.05% accuracy, this uncertainty is reduced to a little more than $1,500 per hour.

External Effects

While most of the oil and gas industry still relies on traditional meters, a Coriolis meter allows for the most accurate direct mass flow measurement, and it measures density at the same time. This allows companies to use density measurement for quality control. A change in the density of a liquid is a clear and unmistakable warning for any operator.

Although it is more accurate than a conventional flowmeter, the accuracy of some Coriolis mass flowmeters is susceptible to external effects, such as pipeline vibration, caused by pumps or the opening and closing of valves or other mechanical devices.

To make things worse, this effect grows with the size of the measurement tubes since strengths and moments increase with the tube size. That means that for high-capacity applications – usually found in any pipeline – immunity to external effects becomes even more important. Temperature, pressure, density, viscosity, vibrations, pulsations and pipe forces are subject to changes in environmental as well as in process conditions.

Software means have been developed to help compensate for errors. However, getting rid of the root cause means ensuring a highly elaborate, robust mechanical design, making sure that the impact on the measurement apparatus is being compensated before the need for any software algorithm even arises.

Decades ago, commercial Coriolis mass flowmeters would usually consist of a sharply bent single measurement tube. They were especially sensitive to vibration as the movement of the tube was not fully decoupled from the housing and piping. Any impact to the piping would be transferred to the measurement apparatus and result in an increased error. For this reason, great care had to be taken during installation to minimize external effects. Still, nowadays some vendors of Coriolis mass flowmeters keep those traditional designs, and call for extra space or reconstruction of the piping or additional mechanical support to reduce the influence of pipeline vibrations on the meter.

Later designs split the flow into two streams and measured the relative movement between the two measurement tubes. As one tube moved to one side, the other tube would compensate by moving in the opposite direction. These designs proved to be much less susceptible to vibration and greatly reduced the need for mechanical support of the piping.

The development of Coriolis mass flowmeter designs went into numerous directions, and the industry saw a variety of differently shaped tubes. Basically, those can be divided into straight and bent tube designs. Straight tube designs have several advantages, like the compactness of the sensor. In an installation, the sensor replaces just a part of the pipeline and does not bulge out. However, in a lot of applications a bent tube is preferred since it allows for larger thermal expansions of the tube relative to the housing. Hence, the meter can be used with higher process temperatures and shows a reduced influence on axial pipe stresses.

For example, Endress+Hauser developed the Promass F series with two slightly bent measuring tubes. Until 2011, two bent tubes remained the state of the art in Coriolis mass flow measurement.

Enter The Four-Tube Coriolis Flowmeter

In May 2011 Endress+Hauser introduced the world’s first commercial Coriolis mass flowmeter with four tubes (Figure 2). The mechanical design of four tubes increases the immunity of the measurement apparatus against external effects even better than the two-tube designs due to balancing in one more dimension.

Figure 2: The four-tube Promass X Coriolis meter consists of two pairs of bent tubes. The first pair is orientated to the left (positive y axis) and the second to the right (negative y-axis).

The four-tube Coriolis meter consists of two pairs of bent tubes. The tube pairs are arranged against each other in such a way that each curve faces the opposite direction. This mechanical symmetry makes the sensor immune to external effects like bending forces, pulsations, vibrations and even cavitation. If one tube is mechanically disturbed in one direction in such a way that its sensor signal is slightly mutated, the opposite tube is disturbed in exactly the opposite direction leading to opposite mutation of its sensor signal; therefore the added sensor signal is not influenced by the disturbance. By having four instead of only two tubes, arranged in a different angle, the direction of compensation is increased by one dimension. This allows for compensating virtually in any direction from which the external effect might come.

Proving Facility In South Of France

To test the accuracy of the new flowmeter under real conditions, measurements on the SPSE (Société du Pipeline Sud-Européen) proving facility were performed. SPSE owns and operates a centralized flowmeter accredited and independent proving facility located in Fos-sur-Mer in the south of France.

Four different crude oils were measured by the Promass X against a ball prover. The measurements were performed under typical process conditions; i.e., large temperature, viscosity and pressure gradients occurred during the measurements due to the solar irradiance and frictional heating from pumping the viscous crude oils. The mass flow was varied from 130 t/h up to 2,800 t/h. This allowed testing performance at low flow rates with very low Reynolds numbers, up to very high flow rates that caused some cavitation with high viscous crude oils. The achieved measuring performance was better than 0.1% (for the three crude oils with a viscosity of up to 70 cP) and 0.2% for the highly viscous crude, for all flow conditions with a repeatability better than 0.05%.

The four tubes also make better use of the circular pipe area. The tube diameter is reduced by about 20% when using four tubes instead of two, while the open pipe area increases from 50% to 68% (Figure 3).

Figure 3: Usage of the circular area of a two-tube and a four-tube design. The diameter of the circle, D, can be filled with two smaller circles of d=D/2 or with four circles of d=D/2.41. Hence, the area increases from 50% to 68% when using four tubes.

In addition, a tube can withstand certain pressures depending on its dimensions and the strength of the material. According to Barlow’s formula, it can be shown that less wall thickness is needed to reach the afforded pressure resistance if the diameter of the tube is reduced. The bending stiffness of the tube correlates with the tube diameter. The smaller the diameter, the smaller the bending stiffness. This allows for a reduced length of the measurement tube while still keeping the same sensitivity or a higher sensitivity at the same length – a significant advantage when designing large Coriolis meters.

Another plus for the revolutionary design of the Promass X is the extreme compactness of the device. While conventional meters that still use sharply bent tubes will naturally take a lot of space, Promass X features the most compact design, allowing for easy handling and easy replacement of conventional meters – without extensive piping work. In addition to that, it is extremely lightweight (starting at 1,330 lbs). Unlike other designs, it doesn’t call for additional support and effortlessly fits into the existing pipe just as it is.

Coriolis Diagnostics

Like every other Endress+Hauser Coriolis mass flowmeter, the Promass X has sophisticated and advanced diagnostics that help minimize maintenance costs. The diagnostic functionality of the Promass device enables customers to really know what is happening inside the pipe.

For many years, customers in all industries had to follow “breakdown maintenance.” That is, “if it’s broke, fix it.” This kind of maintenance does not care about the instrumentation in a plant as long as it still works. As a result, the risk of plant downtime is very high and eventually results in lower safety, higher measurement errors and higher costs.

The goal, therefore, has to be to prevent unexpected failures by using advanced technology and know-how to provide more information on the process as well as the condition of the equipment.

Endress+Hauser’s Advanced Diagnostics is a big step in the direction of predictive maintenance. The concept is based on the fact that the meter reveals warnings prior to failure. By tracking certain signals that can provide insight into actual meter conditions, Advanced Diagnostics allows for early recognition of aberrances in those signals – indicating that the meter conditions have changed. Reasons for these changes could be coating build-up on the measuring tubes or mechanical influences, such as abrasion or corrosion. All of them reduce the performance of the measurement or – in extreme case – could even cause failure.

Be it abrasion or adhesion, gas breakout or particles – the advanced diagnostics make sure the customer is aware of it at any time. Predictive maintenance is not a word anymore; with diagnostics, customers benefit greatly and save additional costs.

Author

Michael Nuber holds a degree in industrial engineering from the Technical University of Darmstadt, Germany. He has several years of experience in the development of flow measurement devices. In 2008 he started working for Endress+Hauser in Switzerland. He heads the company’s Department for Product Management – Coriolis Flowmeters. Contact the author care/of Rich Merritt, The Hebert Agency, 319-393-2917, rmerritt@cedar-rapids.net.

Comments