June 2011 Vol. 238 No. 6

Features

Inline Cathodic Protection: Its All About Current

The external pipeline corrosion control field has seen great change over the years from a regulatory standpoint. However, the field has seen few advances in new technology to assist in monitoring the effectiveness of mitigation efforts. That changed recently with the introduction of an inline inspection (ILI) tool that measures cathodic protection (CP) current flowing on a pipeline.

A.W. Peabody stated in his classic book, Control of Pipeline Corrosion, “When the amount of current flowing (to the pipe) is adjusted properly, it will overpower corrosion current discharging from all anodic areas on the pipeline and there will be a net current flow onto the pipe surface at these points. The entire surface will then be cathodic and the protection complete.” 1

The cathodic protection current measurement tool is an inline inspection tool that measures the voltage drop in the pipe wall that is caused by the accumulation and flow of cathodic protection (CP) current. This voltage is converted to current using Ohm’s law and the data is graphically represented. Let us explore the benefits of this new technology and present case histories of some recent pipeline inspections.

The role that direct current (DC) plays in the corrosion of steel has been clearly understood for many years. It is widely accepted that corrosion takes place at the anode where current is discharging from the steel. Likewise, the role of direct current in CP has been clearly defined since 1823 when Sir Humphrey Davy installed the first CP systems on copper-clad vessels for the British Admiralty. As stated earlier, Peabody theorized that making the pipeline a receiver of current in its entirety would effectively stop corrosion.

Corrosion professionals have a great deal of experience in applying this protective current to pipelines. Galvanic anodes and impressed current rectifiers have been employed to perform this task for many years. The challenge has been how to prove that the entire pipeline is, in fact, receiving current. Many techniques to measure this protective current have been employed. These techniques fall into two categories: 1) measuring CP current flowing down the pipeline and 2) measuring the effect of CP current flowing in the soil to the pipe.

CP Line Current. Some of the methods used to measure CP current flowing on the pipeline include:

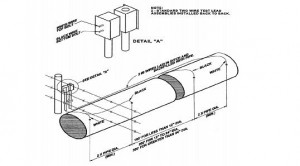

* Insulators installed at inline valves and flanges at key locations with current measuring devices (shunts) installed across the insulators to determine direction and magnitude of current flow down the pipeline (Figure 1).

* IR drop test stations, sometimes called current span or four-wire test stations, installed during new construction to measure the current flowing on the pipeline. These were typically calibrated with an external current source to calculate a calibration factor similar to a shunt factor (Figure 2).

Figure 2.

It has been the author’s experience that these current measuring practices yielded valuable data but they were only snapshots of the current flow on the pipeline system. There was never a sufficient number of these inline current measurement locations to give enough detailed information about the current flow along the entire pipeline.

CP Soil Current. This method typically involves the use of two calibrated reference cells and has often been referred to as the Net Protective Current technique. A technician walks the pipeline with one reference cell over the pipe and the other cell a few feet to the side of the pipe. The voltage drop between the two matched cells due to the flow of CP current to the pipe is then recorded at set intervals. The objective is to prove that current is always flowing to the pipe and not away from it. This is quite similar to a direct current voltage gradient (DCVG) survey. This method has merit but it is difficult to obtain useful data in congested pipe corridors. It is also making indirect and very general measurements on the most complex leg of the CP circuit – the soil. This technique will pick up all current flow – not just the current flow to the target pipeline.

Traditional Monitoring Methods

Traditional CP monitoring for many years has relied on pipe-to-soil potentials. With this monitoring method, one can assess the CP levels at many more points along the pipeline than are typically available for line current measurement. These measured voltages give a good indication of how the current has affected the pipe. When taking a pipe-to-soil potential, the technician is really making an indirect measurement of changes that have occurred at the pipe soil interface due to the flow of current. Some of the challenges to gathering quality data using this traditional method include:

* Right-of-way access issues (urban, rural, industrial).

* Non-conductive surfaces (pavement).

* Congested rights-of-way.

* Waterways.

* High earth currents both AC and DC (IR drop, foreign or third-party CP currents, transit systems, power line corridors).

* Distance to coating holiday (well-coated lines) or pipe/soil interface.

* Time – labor-intensive surveys.

The primary problem with pipe to soil potentials is one of interpretation. There are many outside factors that can influence the potential obtained. There is no doubt that potentials are a valid method of assessing protective levels – as long as we are obtaining the real potential of the pipe steel. In addition, the ability to obtain valid pipe-to-soil potentials at all necessary locations is often problematic.

Consider assessing the protection levels on a typical pipeline 10 miles (16 km) using 1) a traditional test point potential survey, 2) a close-interval potential survey and 3) an inline current survey using new ILI tools.

Traditional test point survey: With traditional test-point potential monitoring methods, a survey of the pipeline’s CP system would typically involve reading 10-12 test points spaced at about one-mile (1.6-km) intervals. This monitoring method gives us a few snapshots of the effectiveness of our corrosion- mitigation efforts. Assumptions must be made as to the protection level between these widely spaced test points. These test points are usually installed with convenience in mind and are rarely found in the locations that would best represent the overall protection levels. IR drop in the soil must be considered for valid interpretation.

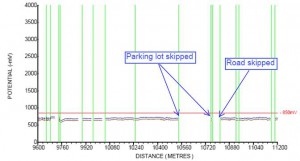

Close-interval potential survey: In an effort to gain more detailed data, a close-interval potential survey might be employed. If a three-foot (0.9-m) interval between readings is used in a close-interval potential survey, this would yield roughly 17,600 data points if 100% of the pipeline could be accessed. This would give a much more complete look at the protection on the line. However, it still requires some interpretation and the survey crew must have access to the top of the pipeline at all points. These surveys require a good deal of preplanning and, once again, IR drop must be considered. Areas with difficult access to the top of the pipe are usually skipped leaving many gaps in the data (Figure 3).

Figure 3.

New ILI current tool: Using the new ILI current measurement technology, the tool (Figure 4) is inserted into a launcher at the beginning of the line and voltage drop data is continuously recorded as the tool is propelled down the pipeline by the product being transported. A voltage drop measurement is recorded every 0.04 inch (1.0 mm) for a total of over 15 million data points, regardless of right-of-way conditions or other obstacles that prevent access to the top of the pipe. The tool is removed at the end of the line and the data is downloaded for analysis. In the analysis process, the voltage drop data is converted to current (Figure 5) and a detailed report is provided to the pipeline operator. This is a true close-interval survey and, unlike the pipe-to-soil survey, the data is free of errors caused by the complexity of outside influences in the soil. Only the current that is accumulating and flowing on the target pipeline is measured. There is no need for IR drop correction, interrupters, landowner notifications, concerns about foreign current sources, or mixed potentials in congested rights-of-way.

Figure 4.

Figure 5.

In addition to giving operators a much more thorough and complete survey with no gaps in the data, there are many other benefits to using an inline inspection tool to evaluate CP systems:

* Access to 100% of a piggable pipeline regardless of the ROW location or condition.

* Cost-effective – people are scarce and expensive. Time to complete a full survey is reduced from weeks to days or days to hours.

* Better utilization of resources – personnel have more time to focus on solving problems by spending less time gathering data.

* Reduced HS&E exposure to personnel in the field.

* Up to three data sets in a single inspection: 1) CP current, 2) inertial mapping and 3) caliper.

* Seamless integration with other ILI data and GIS systems.

* Accurate and repeatable.

* No landowner access issues.

* CP system left on – no interrupters to set and keep synchronized.

* Measures the most stable leg of the CP circuit – outside influences are minimized.

* Locate areas prone to corrosion before damage occurs.

CP current measurement technology gives the pipeline operator a much more comprehensive understanding of the CP system than has previously been available. The data gathered by an inline current measurement inspection reveals:

* Location and output of every current source.

* Extent of coverage area of each current source.

* Midpoints between current sources.

* Shorted casings.

* Areas with significant amounts of induced alternating current (AC).

* An “at a glance” coating quality report based on measured, not assumed current densities.

* Areas with no protective current flow.

Case Histories

8-inch NGL Pipeline

In early 2009, a CP current measurement inspection was conducted on a 105 km (65.2 mi), 8-inch (219- mm) NGL pipeline. This line was constructed in the 1960s of X42, ERW, .188-inch (4.7 mm) wt pipe and coated with coal tar enamel. This line is paralleled by several other pipelines in the same ROW. The purpose of the inspection was to evaluate the effectiveness of the CP system.

Current Sources. The ILI current survey identified and sized the output of five rectifiers protecting this pipeline with a total output of 45.94 amps. The survey also identified two current sources that were previously unknown by the pipeline operator providing 4.27 amps of protective current to the pipeline.

Anomalies. This pipeline had current flow along its entirety. However, two areas were identified that had very low current densities and should be monitored closely. The longest of these “weak” current areas was 54,960 feet (16,752 m) in length and was the result of a previously unidentified short at a valve set.

Shorts/Bonds. The ILI current survey identified and sized five shorts/bonds. The operator was unaware of three of these shorts/bonds. One short/bond was found to have a negative impact on protective levels.

Alternating Current (AC). One particular area of interest was discovered regarding induced AC. A 9,842-feet (3,000-m) area indicated a significant increase in the AC current flowing on the line and then a gradual return to normal levels. Comparison to pipeline alignment drawings revealed several high voltage overhead AC transmission lines in the area of the rapid increase. Subsequently, the area where the AC current returned to normal levels coincided with an area of significant DC current density increase. This would indicate poor coating and most likely the area where the AC is being discharged to ground. Confirmation with field testing is pending.

Casings. This pipeline had 26 cased crossings. No current exchange between the casings and the pipeline was found. Therefore, it was confirmed that none of the casings were shorted to the pipe.

Benefits to Operator. This 1960s vintage coal tar-coated pipeline had an overall current density of 0.0649 mA/ft2 (0.698 mA/m2). This aligns closely with other pipelines of similar age and coating that have been inspected with the CP current measurement tool. This inspection revealed several previously unidentified bonds, current sources and areas of damaged coating that a recent close-interval survey did not identify.

20-inch Offshore Crude Pipeline

In 2009, an inline current inspection was performed on a 112-mile (180 km), 20-inch (508 mm), .500-inch (12.7-mm) wt crude oil pipeline in the Gulf of Mexico. This line was installed in the late 1970s with zinc bracelet anodes providing CP. As these anodes were approaching the end of their design life, a multi-million dollar sled anode retrofit project was completed in 2008. The purpose of the ILI current inspection was to prove up design assumptions, ensure proper operation of the recently installed sled anodes and ensure complete coverage of the CP system.

Current Sources. The inspection located and sized 47 of the 53 anticipated anode sled locations with a total output of 31.4 amps. Six anode sleds were discovered to be non-functional. One additional current source was identified and sized with a total output of 0.24 amps. This additional current source was a tie in to a pipeline system with higher CP levels. To date, one of the six non-functioning anode sleds has been verified by divers and corrected.

Shorts. Six shorts were located and sized during this inspection. All identified shorts were located at subsea pipeline connections. These six shorts were found to be robbing the target pipeline of over 4 amps of protective current.

Anomalies. Eleven areas totaling over 21,000 feet (6,400 m) in length were found to be outside the influence of any current source. This amounts to approximately 4% of the pipeline without the benefit of protective current. Most of these zero current areas were caused by the shorts to other pipelines.

Benefits to Operator. This 1970s vintage coal tar and concrete-coated pipeline had an overall current density of 0.012 mA/ft2 (0.129 mA/m2). This inspection provided the operator with CP system performance data that had previously been unattainable. By identifying the non-functioning sleds, repairs could be made prior to damage caused by external corrosion. Identifying the shorted tie-ins gave the operator the information needed to plan for additional anode material in these areas to overcome the detrimental effect of the shorts.

Conclusion

Inline cathodic protection current measurement is providing CP system performance data to operators that is unattainable with conventional methods. It provides better detail of the CP current flow on a pipeline than any other technology available today. This data is proving valuable in identifying CP system anomalies that may have gone undiscovered for many years. It is also the most reliable method of proving CP current flow to the entire pipeline.

Corrosion professionals have long recognized that CP is all about current. Now there is a tool in the corrosion-control toolbox that can accurately measure pipeline current on the simplest leg of the CP system from inside the pipe. Only the current that affects the target pipeline is considered and the new CP technology can provide that measurement over the entirety of the pipeline without the typical problems encountered in an over-the-line inspection.

Acknowledgment

This article is based on a presentation at NACE International CORROSION/2010 in San Antonio, TX.

Author

Dennis C. Janda is a business development manager with Baker Hughes Pipeline Management Group.

He has 27 years of experience controlling corrosion on petroleum pipelines, well casings, production vessels and tanks. A 25-year member of NACE and certified as a senior corrosion technologist, he graduated from Kilgore College’s corrosion control program in 1983.

Reference

1 Peabody, A.W., Control of Pipeline Corrosion, p. 19, Houston: NACE, 1967.

Comments