April 2012, Vol. 239 No. 4

Projects

Deepwater Discoveries Expected To Drive New Permit Applications

In an interview with Pipeline & Gas Journal, Alex Alvarado, Chief of the Pipeline Section for the Bureau of Safety and Environmental Enforcement’s Gulf of Mexico regional office, talked candidly about the downward trend in pipeline construction in the Gulf and the expected reversal of this trend as a result of recent deepwater discoveries.

P&GJ: How would you describe the outlook for Gulf of Mexico pipeline construction in the near-term?

Alvarado: Currently we are anticipating the reversal of a downward trend that started in 2002, when 2,000 miles of new pipeline construction was approved. With the recent deepwater discoveries and increased drilling activity, we expect that the trend is on the upswing and the reversal will result in an increase in new pipeline permit applications.

P&GJ: Do you see any major obstacle to new pipeline construction in this region in the coming 12- 24 months? If so, what would that be?

Alvarado: From the equipment and technology point of view, we are not aware of any obstacles that would prevent new pipeline construction in the Gulf region. Most of the new deepwater pipeline projects are planned well ahead of time whereby specialized equipment is contracted to make sure it is available for use in the Gulf. One possible obstacle would be the handling of pipeline permits by the staff of the Pipeline Section here at BSEE.

We anticipate filling back job vacancies from recent months and hope to be fully staffed within the next 3-4 months.

P&GJ: There are several methods used to install pipelines in deepwater. Can you briefly discuss these and their respective advantages?

Alvarado: There are two main methods used to lay pipelines: the S-lay and the J-lay methods. A third method, which was developed in anticipation of construction equipment not being able to handle the deeper waters and large size pipelines, was the tow method. However, due to technology being able to keep up with the deeper water installations and loads associated with the laying of major pipelines, this method has not been used. Each method has its advantages that companies take into account depending on different factors such as water depth, size of pipeline, use of rigid or flexible pipe and availability.

The J-lay method is best suited for deeper water depths and can withstand more motion and underwater currents than pipe being laid by the S –lay method, which is better in different depths. Also, in some cases, the J-lay method is the only method that may be used when installing a pipeline riser to an existing floating facility. A variation of the S-lay and J-lay methods is the use of a reel barge. In this case, the pipe is welded onshore reducing the amount of work that is done offshore during the installation.

P&GJ: What deepwater pipeline holds the current water depth record in the Gulf?

Alvarado: The deepest water pipeline in the Gulf and probably in the world is a 10-inch infield pipeline in the Alaminos Canyon area in 9,650 feet of water. The pipeline is associated with the Perdido Norte project.

P&GJ: In which leasing areas are companies looking to install new deepwater pipelines?

Alvarado: The deepwater areas where companies are planning on installing new pipeline are the Walker Ridge and the Keathley Canyon. Some of these pipelines will be in the range of up to 200 miles in length to bring the production to existing shallow water infrastructure.

P&GJ: How many permits for new pipeline installations did your agency receive last year? Of these, how many were approved?

Alvarado: During calendar year 2011, we received total applications for 266 different pipeline segments of which 203 were approved during the year. The 63 segments that were not approved were most likely those submitted in the latter part of the year and may be approved this year.

P&GJ: Has the pace of permitting for pipelines slowed in the aftermath of the Gulf spill?

Alvarado: As I indicated earlier, we had been in a decline trend in the number of miles and segments included in applications since 2002. However, before the BP spill, 2009 was the first year since 1994 that we did not break the 1,000-mile threshold for miles approved per year.

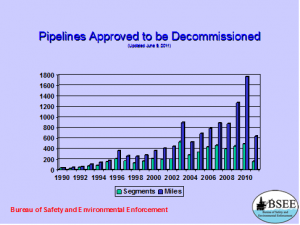

One possible explanation is that companies were focusing on decommissioning pipelines due to the Idle Iron initiative to decommission out-of-service facilities with no future utility. The accompanying slide shows an increase in the number of pipeline miles and segments that were approved to be decommissioned in recent years.

P&GJ: How many miles of oil and gas pipelines were completed in the Gulf in 2011?

Alvarado: Based on project completion reports received by BSEE, there were 84 miles of oil pipelines and 35 miles of gas pipelines installed in 2011.

Alex Alvarado is Chief of the Pipeline Section for the Bureau of Safety and Environmental Enforcement’s Gulf of Mexico regional office. His responsibilities include oversight of the BSEE Gulf of Mexico regulatory program to assure safe and environmentally sound transportation of hydrocarbons by pipeline.

Alvarado is also responsible for the review and approval of all OCS pipeline permits for the Gulf of Mexico and Atlantic Region, and for developing regulations to assure safety in design, construction, testing, operation, maintenance and repairs of offshore pipelines. He has a Bachelor of Science in Electronic Engineering from the University of Texas-Arlington. He has worked for the Minerals Management Service (MMS) now BSEE for 33 years in different managerial positions. He can be reached at Alex.Alvarado@bsee.gov.

Comments