September 2012, Vol. 239 No. 9

Features

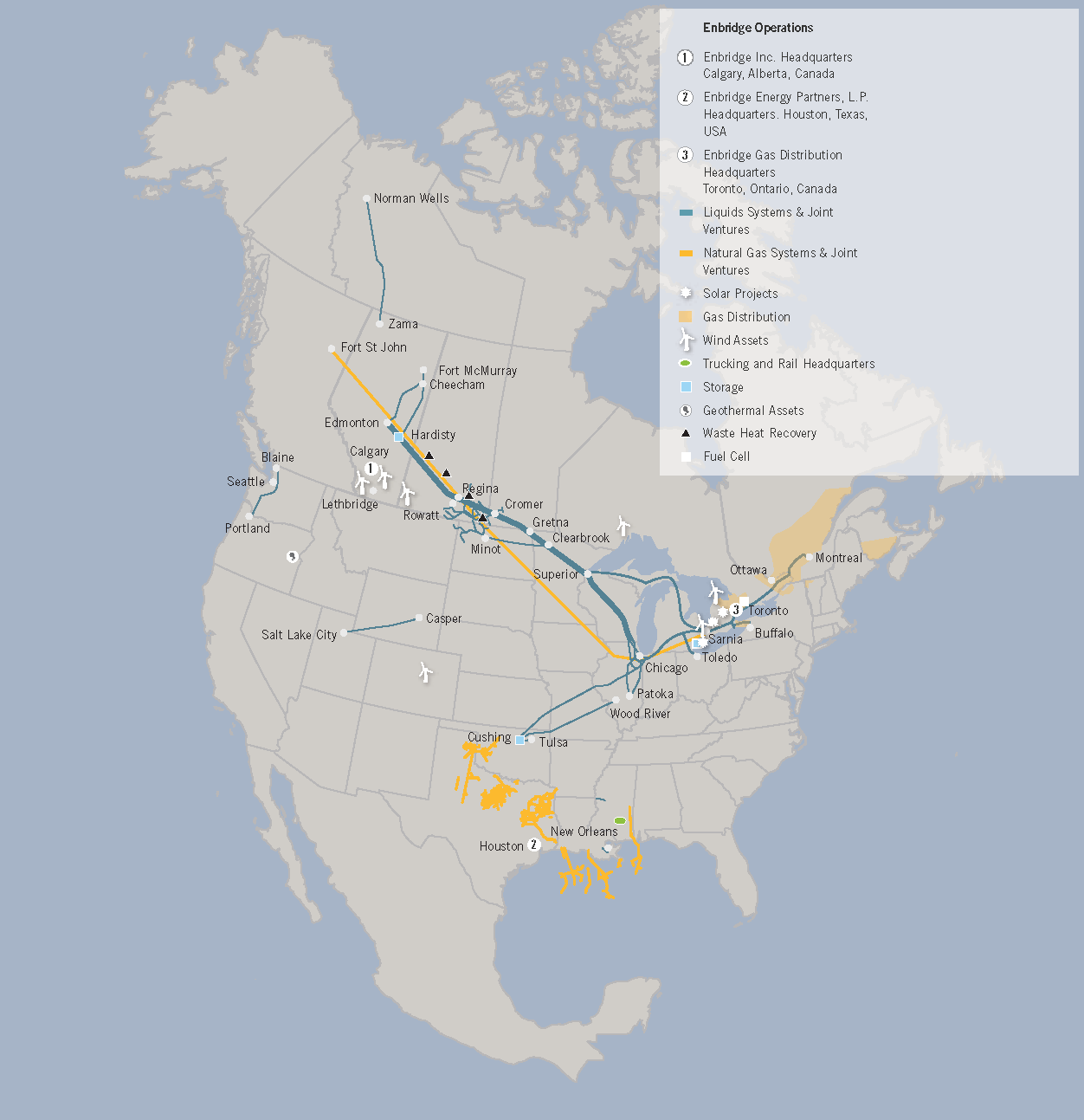

Enbridge Says Its Pipeline System Safe

Enbridge Inc., whose pipelines ship the bulk of Canada’s oil exports to the United States, defended the record of its system on Aug. 3 after the U.S. Pipeline and Hazardous Materials Safety Administration (PHMSA) voiced concerns about the safety of its operations following a series of spills in the upper Midwest.

PHMSA had initially refused to allow Enbridge to reopen its 317,600-bpd, 24-inch Line 14 after a rupture spilled 1,200 barrels of oil into a Wisconsin on July 27. No one was injured and the oil was contained in a field, mostly on the pipeline right-of-way.

PHMSA ordered Enbridge to ensure that its 1,900-mile Lakehead Pipeline system is safe before it would be allowed to resume shipments on the line. On Aug. 7 Enbridge Energy LP announced Line 14 was safely restarted after having received permission from PHMSA. The line, installed in 1998, predominantly transports light crude oil to Chicago-area refineries. It is part of the Partnership’s Lakehead System and owned by Enbridge Energy, Limited Partnership, a subsidiary of the Partnership.

This incident followed a series of spills culminating in a major rupture in September 2010 that poured more than 20,000 barrels of crude into Michigan’s Marshall River system.

The embattled pipeline giant insists that the number and size of spills from pipelines have decreased over the past decade and that, despite some high-profile accidents, the company’s record is good.

“Over the last decade we’ve transported almost 12 billion barrels of crude oil with a safe delivery record better than 99.999%,” Al Monaco, Enbridge’s president, said in a prepared statement. “That’s good, but for us, it’s not good enough. We will never stop striving for 100%.”

In a rarely used amendment to a Corrective Action Order issued on Aug. 1, PHMSA said it has concerns about what it called “a pattern of failures” on Enbridge’s system over the past several years and demanded the company present a comprehensive plan, overseen by an independent third party, to improve its operations. Enbridge submitted the plan on Aug. 2 but had not yet received a response from PHMSA.

Enbridge said it will spend C$800 million ($800 million) this year improving the safety of its pipeline network, twice what it spent in 2011.

“Over the past two years we have doubled the number of staff dedicated to leak detection and pipeline control systems, and substantially strengthened our focus on the tools, technologies and strategies to ensure the fitness of our pipelines,” Monaco said.

Enbridge posted a news release on its website stating that it has installed new improvements and initiatives in pipeline integrity, safety and operations designed to improve the company’s overall performance.

“Enbridge and Enbridge Energy Partners has worked closely and cooperatively with the NTSB (National Transportation Safety Board) throughout its investigation, and is now reviewing the summary report in detail. Enbridge will not provide detailed statements on the specific contents of the final report until it has been issued and our analysis is complete.

“Enbridge has already implemented, in 2010 and 2011, appropriate operational and procedural changes based on its own detailed internal investigation. Enbridge will continue to carefully examine the NTSB reports to determine whether any further changes are required.

“Enbridge’s overarching objective and business priority is to ensure the safety and reliability of our delivery systems for the people who live and work near our pipeline systems across North America, our employees and our customers.”

In direct response to the Marshall accident, or as part of its ongoing improvement initiatives and activities, Enbridge says it has taken the following steps:

Pipeline And Facility Integrity

* Further heightened the importance and goal of our pipeline and facility integrity program.

* Re-organized the functional areas that are responsible for pipeline and facility integrity.

* Enbridge has always taken an aggressive, proactive approach to pipeline integrity management, and was spending approximately $150 million per year on pipeline integrity testing and management prior to the Marshall incident. Enbridge has also been one of the largest users in the world of high technology inline inspection tools.

* Following the Marshall incident, Enbridge further substantially increased pipeline integrity management spending to over $450 million in each of 2011 and 2012, and has performed more than 175 inline inspections and nearly 3,000 pipeline excavations during that time.

* Undertook hundreds of internal inspections and thousands of investigative digs.

* Placed a renewed emphasis on the safety of our overall system.

Leak Detection

* Established the Pipeline Control Systems and Leak Detection department, doubling the number of employees and contractors dedicated to leak detection and pipeline control.

* Enhanced procedures for leak detection analysis.

* Implemented a Leak Detection Instrumentation Improvement Program to add and upgrade instrumentation across our system.

Pipeline Control and Control Center Operations (CCO)

* Developed a Control Room Management (CRM) plan based on the U.S. Code of Federal Regulations and implemented a number of the sections, Oct. 1, 2011, remaining sections implemented by Aug. 1, 2012.

* Revised and enhanced all procedures pertaining to decision making, handling pipeline startups and shutdowns, leak detection system alarms, communication protocols, and suspected column separations.

* Enhanced the organizational structures to better support our operators and to manage span of control and workloads.

* Augmented CCO (Control Center Operations) staff, adding training, technical support, engineering and operator positions.

“Prior to the accident, we had embarked on the design and construction of a new, world-class Control Center in Edmonton, Alberta. The new center was opened in December 2011 and significantly enhances the work environment for our operators and allows greater interaction and support for 7 x 24 hour operations.”

Public Awareness

* Reviewed and strengthened Public Awareness Programs across its operational areas in both the U.S and Canada.

* Developing an industry-leading online and in-person training tool to provide Enbridge-specific information to emergency responders.

In the U.S.:

- Formalized the U.S. Public Awareness Committee.

- Improved the Program Effectiveness Evaluation process.

- Provided annual employee training for field employees across the company’s U.S. operations.

- Created a Public Awareness Hotline.

In Canada, we:

- Formalized the Canadian Public Awareness Committee.

- Are creating a Canadian Public Awareness Database.

- Improved the landowner/tenant database.

- Developed a landowner newsletter.

- Established Community Relations positions in each region.

Emergency Response

* An incremental $50 million will be spent between 2012 and 2013 (projected) to improve equipment, training and overall response capabilities.

* Develop better tools and techniques for worst-case waterborne spills.

* In 2011, a cross-business unit response team was created for large-scale events requiring more resources that a single region could provide.

* In 2011, created a dedicated Emergency Response group in Operation Services for increased regional support.

* Conducting an Emergency Response preparedness assessment to enhance abilities to more rapidly respond and contain a significant release.

Safety Culture

* Reinforced a high level of safety and operational integrity across Enbridge in integrity management, third-party damage avoidance and detection, leak detection, incident response capacity, worker and contractor occupational safety, public safety and environmental protection.

* Implemented “Lifesaving Rules” and training for all Enbridge employees and contractors. The Lifesaving Rules are designed to highlight key process and rules that, if not followed, could put people’s lives at risk. They have been implemented enterprise-wide.

* Introduced new Safety Culture training sessions for all employees.

* Renewed focus on risk assessment and research and development.

Comments