March 2014, Vol. 241 No. 3

Features

Advance in Corrosion Protection Supports Pipeline Applications

Keeping field equipment safe and reliable is vitally important to ensure ongoing operations at pipeline and gas installations. However, due to corrosion, devices for replacing and repairing equipment can rapidly become expensive, especially when the related system downtime is also considered. To address this problem, corrosion protection should be a prime focus in the field of electric actuation.

Electric actuators automate industrial valves of any type and size. In compliance with the operational commands issued by the distributed control system (DCS), or the setpoint definitions, the equipment adjusts valve positions and contributes significantly to the precise control and regulation of medium flows. Electric actuators are used wherever pipework or industrial valve automation is needed. Actuators are found across all oil and gas applications including pipelines, oil drilling rigs, tank farms and gas tanks.

Sophisticated Demands

During the last decade, the growth in both pipeline and offshore applications for actuators has led to increased quality demands for corrosion protection. Installation relying on actuators includes principal oil arteries.

Transpetrol, an independent shipper, relies on actuators to supply one of the world’s biggest oil pipeline networks, which carries oil more than 2,500 miles from the eastern region of European Russia to locations that include Ukraine, Poland, Hungary and Germany. The Družba pipeline is the principal trans-European artery for transportation of Russian and Kazakh oil across Europe.

Additionally, modular electric actuators have been adapted to meet the flow control needs of Gazprom gas compressor stations in Siberia. To date, more than 200 explosion proof actuators with integrated controls and high speed, part–turn gearboxes have been supplied.

Continuous developments in exploration engineering, along with soaring energy costs, have resulted in intensified oil and gas extraction under increasingly extreme environmental conditions in the open sea. Electric actuators are now in use from the tropics to the polar latitudes.

The humid and salty atmosphere in offshore installations exposes electric actuators to extremely corrosive conditions. Importantly, downtime in installations of this type is typically higher than for installations onshore. Consequently, operating companies have become increasingly aware of corrosion-protection issues. Additionally, corrosion damage, which can cause issues such as seized screws, prompts an increased risk of functional and maintenance difficulties.

Corrosivity Classifications

A key requirement when addressing the issue of corrosivity is an understanding of relevant classifications. For planning engineers and operators, the second part of EN ISO 12944 forms a solid basis for classification of environmental conditions. Descriptions are provided along with corrosivity classification categories (Figure 2).

Actuators provide valve control service over many years. As a result, they demand long protection times. The categories are subdivided in exposure protection times: short, medium and long. In offshore areas, corrosivity category C5-M must be fulfilled.

The requirements described in the EN ISO 12944 standard are sometimes considered insufficient. NORSOK, the M-501 standard established by the Norwegian oil industry, goes beyond the requirements of EN ISO 12944: this standard is based on the extremely demanding corrosion protection test described in IS0 20340 in which specimens are subjected to a climatic test over the course of 25 weeks under cyclic changes of climatic conditions.

The central focus of the corrosion tests described in any standard is the salt spray test that is in compliance with EN ISO 9227 (NSS-neutral salt spray). For this test, scribe lines that cut completely through the paint coating of the parts into the metal substrate are made. The test devices are then subjected to saline atmospheres within a closed spray cabinet and evaluation is performed in compliance with standardized criteria. When testing C5-M with long protection times, as specified by EN ISO 12944-6, the test duration amounts to 1,440 hours. For ISO 20340, the spray duration within the cyclic climatic test totals up to 1,800 hours.

All standards show the same limitations. They do not yet consider the recent advancements in powder-coating technology. Consequently, the action lists disregard this type of corrosion protection, despite the fact it has been established and proven for many years. In AUMA’s opinion, this is due to protracted standardization procedures.

Powder Coating Sets Benchmark

In light of the increased environmental demands for production facilities, AUMA addressed its existing coating method for its actuator components. After an extensive evaluation phase, the company spearheaded an initiative to implement a two-layer powder coating of housing parts. A major investment of several million Euros was required to develop a powder- coating facility for the company’s actuator housings; a crucial paradigm shift was made with a move from wet painting completed devices to powder coating individual housing parts prior to assembly. This is of significant advantage to plant operators because even when the device housing is repeatedly opened – whether during installation, commissioning or overhauling – the corrosion protection coating remains intact.

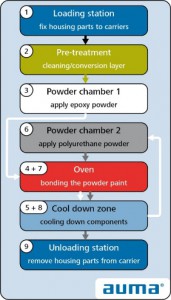

Due to the challenges of the extremely thin dimensions of the two-layer paint system, the individual housing parts had to be adapted, relating to the proportions and design. An additional, self-imposed objective was also met by the manufacturer’s powder-coating development: housing parts are now coated beyond the joints, thus further improving the devices’ corrosion protection properties. (Figure 3).

Powder Coating Processes

Prior to applying the powder layers, components are subjected to a wet chemical pre-treatment, removing grease and contamination and activating the surface. The resulting conversion layer ensures bonding of the powder to the housing surface. Silane technology (OXSILAN®) is used instead of conventional zinc phosphate treatment, offering identical quality but improving sustainability to environmental protection.

For the primer layer (Figure 5), electrostatic-charged epoxy powder is applied to the earthed housing parts in an appropriate powder chamber. The electrostatic charge ensures that the powder adheres evenly to the material beyond the joints. The carriers with the components travel from the powder chamber to an oven where the powder is cured. Epoxy powder then adheres to the surface, contributing to the exceptional mechanical resistance of the coating.

Similarly, polyurethane finish powder is applied in a further process. This coating offers high protection from chemicals, weather and UV impact. Both powder layers are optimally adapted to each other, particularly concerning bonding between primer and finish powder.

Regarding powder coatings, the desired properties could not be achieved with commercially available products. Therefore, in cooperation with a paint manufacturer, a custom-made formula was created with metal particles incorporated in the finish coating powder to provide enhanced coating quality. The complete process (Figure 6) is fully automated, ensuring consistent coating quality.

If desired, the devices can be coated with a final wet paint layer. This is required if the devices are ordered in a special color, or if the device specification defines superior minimum layer thickness. In terms of corrosion protection, this is not required. Although the film thickness at 140 µm is rather low, powder coating fulfills the requirements of corrosivity category C5-M with a long protection time, even when applying the stricter test specification of ISO 20340.

The corrosion-protection system described was subjected to a 2,520-hour spray test which was halted as no significant corrosion damage could be detected. As a result, the duration required by the standards was exceeded, and the complete cycle, according to ISO 20340, was performed and certified.

Additional Actions

The actuator manufacturer emphasizes that corrosion protection is not limited to powder coating. Some outer elements of an actuation device are not appropriate for this procedure. For example, control and display elements, nameplates, screws and the handwheel shaft are made of materials such as stainless steel, or are protected with application of different coatings. If different materials are combined, under certain conditions corrosion can appear at joints. In order to avoid so-called “contact corrosion,” extensive tests were performed to eliminate unfavorable material combinations.

Conclusion

AUMA finds there are no comparable effective corrosion protections available on the actuator market. However, for suppliers of automation devices to the process industries, this is an important investment as plant and pipeline operators are increasingly unwilling to accept downtime due to inadequate corrosion protection.

Comments