October 2014, Vol. 241, No. 10

TechNotes

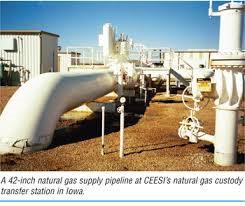

CEESIowa Marks 15th Anniversary

This year CEESIowa is celebrating its 15th year in operation. Since its first flow in March 1999, CEESIowa has provided high-quality, independent third-party natural gas flow calibrations to the energy industry.

Although CEESIowa calibrates many types of meters including cone meters, subsonic venturis, turbine meters, and Coriolis meters, a good portion of CEESIowa’s calibrations are ultrasonic meters. In the last 15 years, the facility has seen the USM metering technology grow and advance significantly.

As the technology has advanced, CEESIowa has improved as well. With ongoing efforts to continually improve measurement, CEESIowa has improved the lab uncertainty, along with the rangeability of the facility, calibrating as small as a 3-inch, and as large as a 36-inch USM.

Measurement departments are constantly trying to improve as well. With many pipelines attempting to balance their systems to sometimes less than 0.1%, it is critical to achieve a high quality of measurement at all phases. Having a quality calibration becomes an important part of that process. Due to the quality, consistency and reproducibility of CEESIowa, many CEESI customers achieve their goal of less than 0.1% balance within their systems.

Fifteen years ago, users would typically only send a meter and some straight inlet pipe for their calibration. In the last 15 years, there has been a great deal learned about USM performance. Today, in an effort to reduce uncertainties, many users are sending entire metering skids to account for installation effects and calibrate these effects out.

One of CEESIowa’s strengths is the ability to handle and install these large skids and calibrate the entire skid, rather than just a meter with straight inlet pipe. This becomes another step in trying to achieve ideal system balances once the meter is installed.

In addition to quality measurement, one of CEESIowa’s goals is to provide a high level of outstanding customer service. Another strength is flexibility in scheduling, knowing that project delays happen, or hot projects sometimes pop up unexpectedly. As a result, the team is ready to react to a customer’s needs in order to perform a calibration with little notice to help keep a project on schedule. With proper coordination, they can receive the meter(s), install them in the CEESIowa system for calibration, and have them back on the road in less than 24 hours.

As part of its contribution back to the industry, CEESIowa donates two weeks of lab time to conduct USM research. Every year, the North American Fluid Flow Measurement Council (NAFFMC) plans and conducts new USM research. The latest research results are then presented annually at CEESI flow measurement workshops and conferences around the world. Through the years, CEESI has conducted USM research focusing on installation effects, header effects, low flow effects, flow conditioner blockage, and low flow temperature effects, to name a few.

CEESIowa continues to grow and expanding its facilities. They have acquired an existing building enabling them to remodel and expand the current office, adding office space for increased convenience of visiting customers and larger groups.

Nearly every week CEESIowa has visitors from North America and around the world. Located only 8 miles from Clear Lake, IA which is known for the Surf Ballroom where Buddy Holly, Ritchie Valens and The Big Bopper last performed, CEESIowa offers many tourist attractions locally and is also only 4 miles from the spring-fed lake.

Comments