November 2018

Features

Improving Methane Emissions from Natural Gas Transmission, Storage

By INGAA, Environmental, Health and Safety Committee

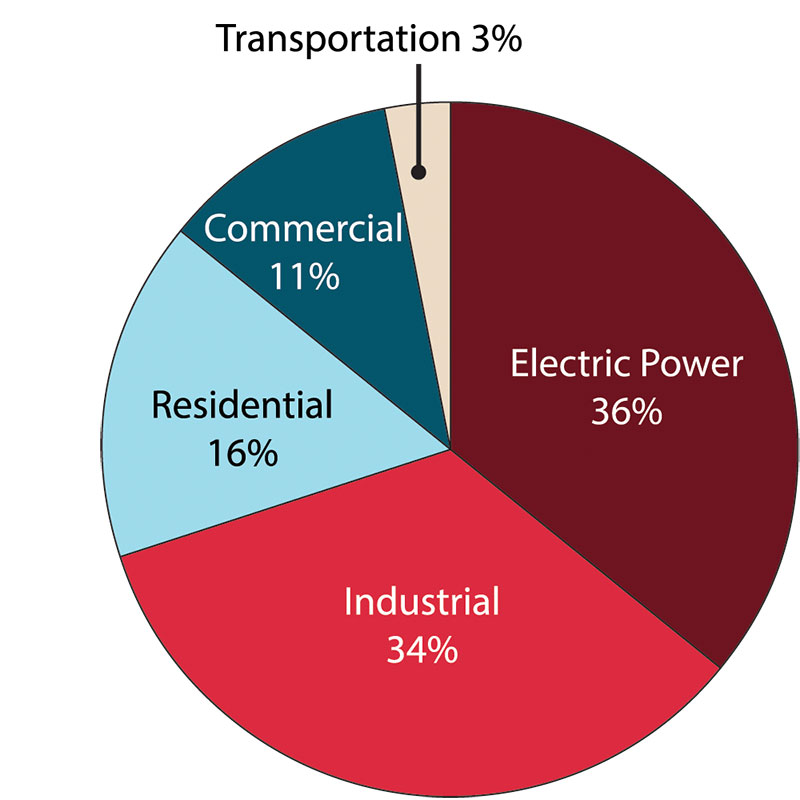

Natural gas plays an important role in our modern lives, helping to diversify the nation’s energy portfolio by providing a reliable source of energy generation that complements renewable sources that have variable generation. (Graph 1)

Pipelines serve as a reliable and indispensable link between natural gas producers and consumers. For example, INGAA-member companies move natural gas through interstate natural gas pipelines, which supply 68.4 million homes and 5.5 million commercial businesses with natural gas for heating and other resources.

As major transporters of natural gas, INGAA member companies are committed to minimizing methane emissions from natural gas transmission and storage facilities. In 2018, INGAA member companies developed voluntary methane emissions commitments for their interstate natural gas transmission and storage facilities. [Related Story: INGAA Board Affirms Commitment to Minimizing Methane Releases]

This article explains the sources of methane emissions for the interstate natural gas transmission and storage sector, which is comprised of a network of high-pressure pipelines, compressor stations and storage assets (salt caverns and reservoirs), as well as the basis for the methane emissions commitments that INGAA members voluntarily adopted.

When developing methane commitments, INGAA members recognized that flexibility is essential to a successful voluntary methane emission reduction program. Providing flexibility affords operators the ability to focus resources on opportunities to minimize methane emissions in a cost-effective manner rather than strictly adhering to prescribed criteria.

Methane Emissions

Natural gas is a mixture of several types of hydrocarbon gases, the primary component of which is methane.

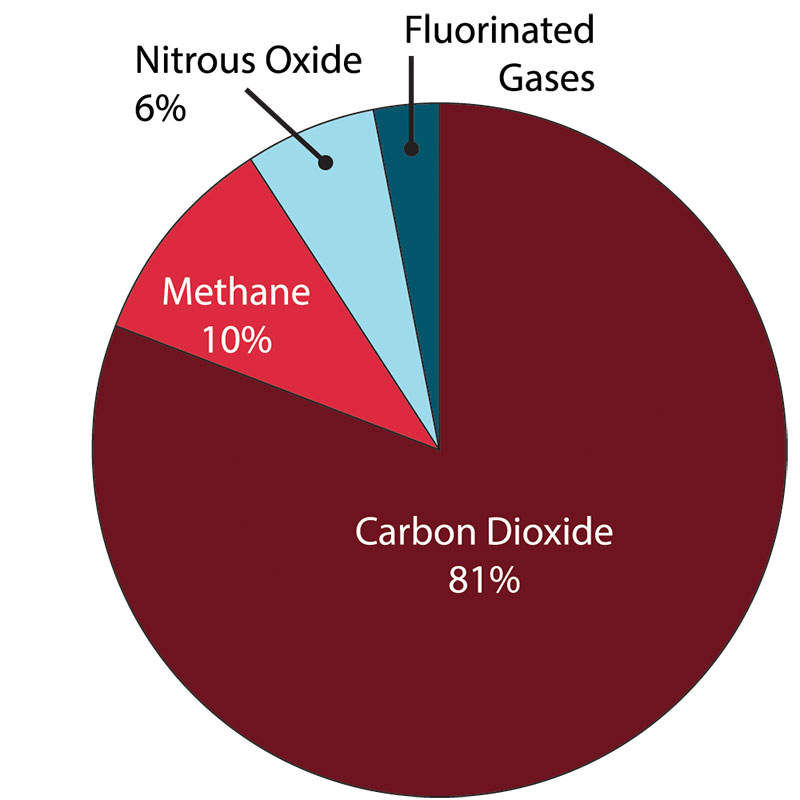

The natural gas transmission sector transports pipeline-grade natural gas that meets certain requirements and is typically over 90% methane. Methane is a greenhouse gas (GHG) with a global warming potential (GWP) that is 25 times more potent than carbon dioxide (CO2) over a 100-year horizon.

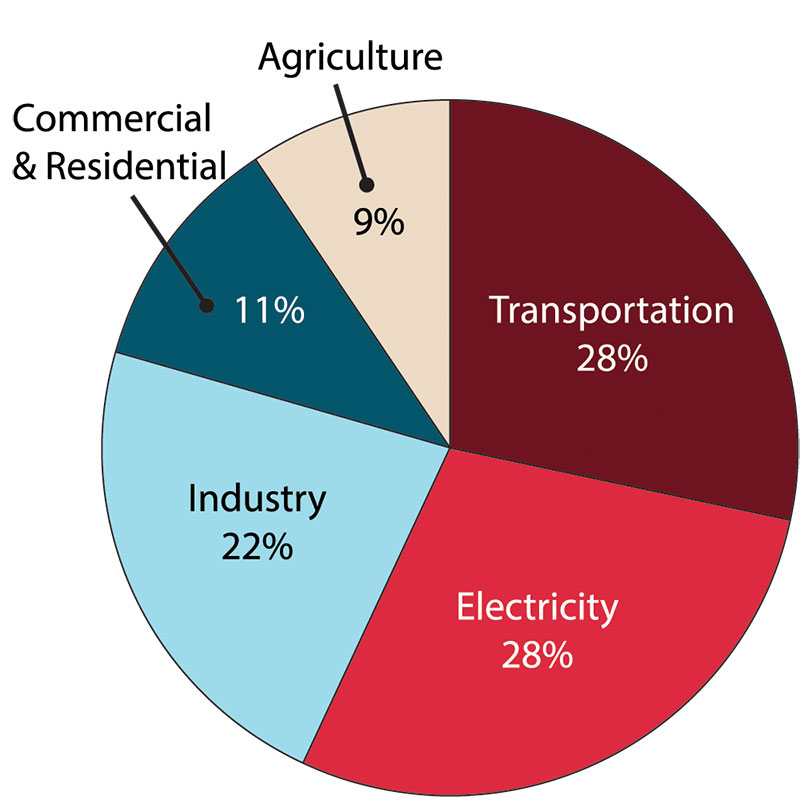

GHG emissions come from a variety of sources, including electricity generation, transportation, industrial activities, commercial and residential activities, and agriculture. Electricity generation and transportation are the two largest sources of GHGs in the U.S., each contributing 28% of U.S emissions. (Graph 2).

In recent years, electricity generation using natural gas has increased, often replacing coal-fired generation, and, as a result, CO2 emissions in the U.S. have decreased.

This trend is projected to likely continue. CO2 accounts for over 80% of GHGs (Graph 2); at only 10%, methane comprises a much smaller percentage of U.S. GHGs. Emissions from “industry” is the third-largest source of U.S. GHGs. (Graph 2, Graph 3)

Reduction History

Since 1993, the U.S. Environmental Protection Agency (EPA) has collaborated with the U.S. oil and natural gas industry on its voluntary Natural Gas STAR Program.

The program provides a framework for partner companies to implement methane-reducing technologies and practices and document their voluntary emission reduction activities.

“Through this work, the oil and natural gas industry has pioneered some of the most widely used, innovative technologies and practices that reduce methane emissions,” the EPA said.

By measuring, monitoring and reducing the transmission and storage sector’s methane emissions for over two decades, INGAA member companies have gained knowledge regarding the sources of methane emissions.

This experience has enabled the industry to target the most significant sources and identify the most cost-effective methane emission reduction strategies. To reduce methane emissions, the natural gas transmission and storage sector has taken steps, such as:

- Evaluating improvements to the energy efficiency of facilities (compressor stations, underground storage, etc.)

- Monitoring leaks from compressors

- Implementing inspection and maintenance methods to reduce equipment leaks

- Using pneumatic devices that have low or no methane emissions

- Employing advanced technologies and management practices that reduce the amount of methane released during maintenance and inspections

As a result, the natural gas transmission and storage sector has significantly reduced its methane emissions. Some of these successes include decreasing the methane emissions from transmission and storage facilities by 44% from 1990 to 2016 due to reduced compressor station and fugitive emissions, despite a 43% increase in U.S. natural gas consumption during the same time frame.

Methane emission reduction measures taken by the natural gas transmission and storage sector played a significant role in decreasing methane emissions from natural gas systems, with emissions from the overall natural gas value chain decreasing by 16% since 1990, even while U.S. natural gas production increased by 45%.

A recent report from the Pipeline Research Council International (PRCI) analyzed over 14,000 measurements conducted at transmission and storage facilities for Subpart W of the GHG Reporting Program.

The PRCI study indicates that the average transmission and storage facility leak emissions are 37% lower than EPA’s estimates of facility leak emissions.

Additional actions that INGAA member companies have taken to reduce methane emissions include engaging with the U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) to ensure new natural gas pipeline safety and storage regulations consider methane emissions.

PHMSA’s Interim Final Rule on Underground Natural Gas Storage was the result of collaboration between regulatory agencies, industry, and other stakeholders to develop widely accepted recommended practices designed to prevent and mitigate integrity breaches, leaks and failures at natural gas storage facilities.

PHMSA largely adopted those recommended practices as regulations that are now applicable to over 400 storage fields with a combined working capacity of 4.8 Tcf of natural gas. The regulations provide design, construction, operation and reporting requirements for natural gas storage. These requirements were adopted with a goal of keeping natural gas safely confined within storage facilities.

Likewise, INGAA members have voluntarily committed to applying risk management programs used to prevent and detect pipeline defects and leaks to cover more pipeline mileage than required by existing regulations.

Industry is also working with PHMSA to encourage the adoption of advanced inspection technologies and to allow integrity management practices when new structures are built near a pipeline. Such practices may be preferable to replacing pipelines because pipeline replacement requires removing all of the natural gas from the pipeline (commonly referred to as a “blowdown”).

Additionally, INGAA member companies are:

- Conducting leak inspections and measurements at transmission and storage facilities that are subject to U.S. EPA’s Greenhouse Gas Reporting Program (40 C.F.R., Part 98).

- Working with EPA on concepts related to leak detection, which influenced the best management practices identified in EPA’s Methane Challenge Program.

- Participating in research programs and studies to identify additional methods for detecting, quantifying and reducing methane emissions.

- Analyzing the data reported under EPA’s Greenhouse Gas Mandatory Reporting Rule to improve this information and identify additional opportunities to reduce methane emissions.

Transmission, Storage

Within the natural gas transmission and storage sector, emissions broadly fall into two categories: facility (compressor stations, underground storage facilities, etc.) or pipeline. There are three main categories of emissions from facilities and pipelines:

Compressor stations: Emissions that occur

(1) during maintenance, compressor startups, compressor shutdowns and emergencies

(2) Controlled venting: emissions associated with maintenance or other site activities (i.e., blowdowns, pneumatic controllers, etc.).

(3) Fugitive emissions and leaks: unintended emissions from equipment that occur from components, such as flanges, connectors, seals, valves, and meters

According to EPA’s annual GHG Inventory, the transmission and storage sector accounts for 20% of the total methane emissions from the oil and natural gas industry.

In 2016, the largest sources of methane emissions from this sector were: reciprocating and centrifugal compressors leaks; other compressor station leaks; engine exhaust; natural gas pipeline venting; compressor station venting; and releases from pneumatic controllers. A combination of other sources accounted for 6% of emissions.

Station Emissions

According to the information collected pursuant to EPA’s annual GHG inventory, the majority of the methane emissions from the natural gas transmission and storage sector come from the processes at compressor stations.

For this reason, INGAA member companies made several voluntary commitments to reduce methane emissions from natural gas transmission and storage compressor stations.

The natural gas transmission and storage sector uses compressors to increase the pressure of natural gas, so it can move along the pipeline. The majority of the methane emissions at a compressor station generally come from four types of sources: reciprocating compressors, centrifugal compressors, compressor station fugitive emissions, and venting.

Within those broad categories, emission sources can be further broken down as follows:

- Reciprocating compressors – rod packing and valve leakage

- Centrifugal compressors – wet seal degassing vents and valve leakage

- Compressor station fugitives – connectors, valves, open-ended lines, pressure relief valves, meters

- Venting – emissions that occur when depressurizing compressors; these emissions are released by design through engineered pathways

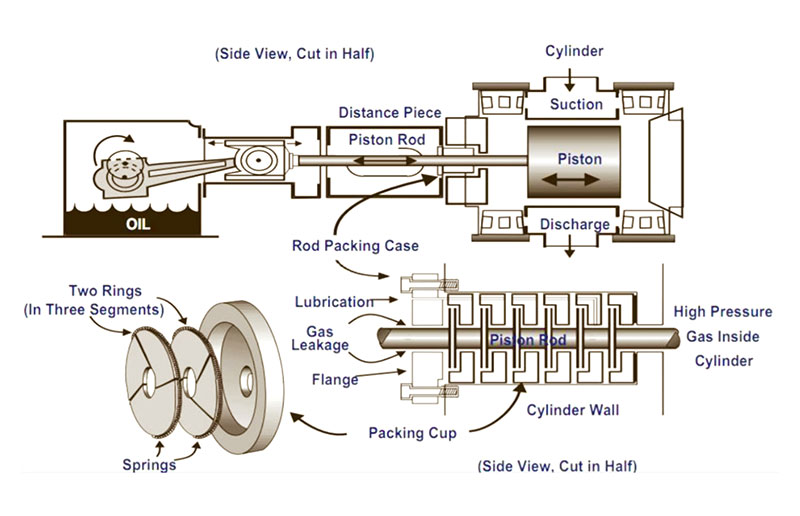

Reciprocating compressors use packing systems “to maintain a tight seal around the piston rod, preventing the gas compressed to high pressure in the compressor cylinder from leaking, while allowing the rod to move freely.”

Even when rod packing is new, it is designed to leak at a low rate when the compressor is operating (such as when the rod is moving back and forth).

As the rod packing on reciprocating compressors wears, leak rates increase. To reduce these emissions, the rod packing on reciprocating compressors must be replaced periodically. California, for example, has adopted a methane regulation that allows a leak rate of 2 standard cubic feet (scf) per minute (or 120 scf per hour) before maintenance is required. (Diagram 1)

Changing rod packing at a prescribed interval poses the risk of scheduling an additional maintenance window to clear the natural gas from the equipment, which may potentially increase methane emissions beyond those from the leaking rod packing.

An alternative approach is predictive or condition-based maintenance, in which operating conditions are monitored and maintenance decisions are based on either performance or defined conditions, rather than adopting a specific frequency for maintenance.

Condition-based maintenance practices may extend the operation of functional rod packing and preclude premature and wasteful rod packing maintenance/replacement. In other cases, condition-based maintenance may identify rod packing that requires replacement on a more frequent basis than the prescribed interval.

As part of the voluntary EPA Natural Gas STAR program, EPA issued a “lessons learned” document entitled “Reducing Methane Emissions from Compressor Rod Packing System,” which provides examples of conditioned-based maintenance practices.

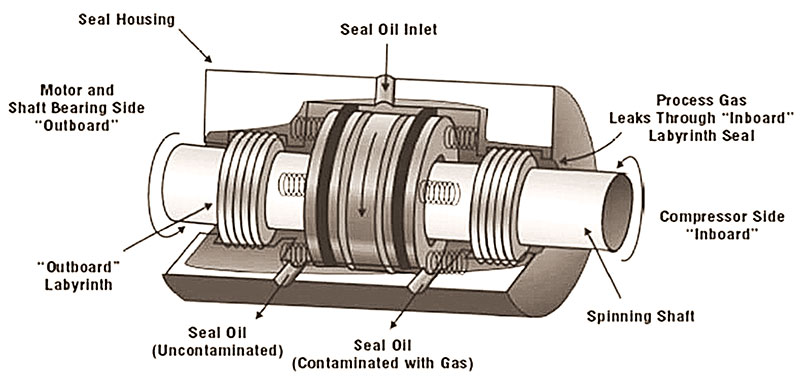

Wet or dry seals on centrifugal compressors. Centrifugal compressors have seals located on the rotating shafts to prevent natural gas from leaking from the point where the shaft exits the compressor casing. (Diagram 2)

Given that dry seals have been the industry standard on centrifugal compressors for well over a decade, INGAA member companies concluded that it was unproductive to focus on emissions from centrifugal compressors.

Furthermore, installing vapor recovery systems, thermal oxidizers or flares for seal oil degassing vents is not a common practice within the natural gas transmission and storage sector. This technology is not yet a proven technology for widespread use outside a few limited situations (Alaskan operations).

Fugitive Emissions

Equipment fugitive emissions (leaks) are unintentional releases of natural gas from piping and process equipment. Components that may leak at a compressor station include flanges, valves, and fittings on compressors. The annual EPA GHG Inventory indicates that the majority of leak emissions are from reciprocating and centrifugal compressors.

In the inventory, “reciprocating compressors” includes methane emissions from rod packing, and leakage through compressor blowdown valves and isolation valves.

“Centrifugal EPA, compressors” includes methane emissions from wet and dry seals, and leakage through compressor blowdown valves and isolation valves. EPA’s GHG Reporting Program requires measurement of compressor leaks, and data from Subpart W of the GHG Reporting Program further validates the conclusion that other station fugitive emissions (from yard piping) are typically small compared with typical emissions from leaks associated with compressors.

An equipment leak may only represent a small percentage of overall losses; yet, leaks are often the subject of intense focus by outside parties. However, not all leaks are created equal. For example, some leaks are larger than others. In fact, a relatively small percentage of leaks contribute the vast majority of emissions for natural gas operations – 95% of methane emissions from equipment leaks are from a mere 20% of the leaks at compressor stations.

PRCI’s report reviewing Subpart W measurements showed that mitigating less than 3% (by count) of the leaks associated with compressor seals, isolation valves, and blowdown valves could reduce total compressor station leak emissions by 60% relative to EPA’s most recent estimate of facility leak emissions.

Furthermore, some leaks are more complicated to repair than others. Repairing all leaks is not always prudent because methane emissions associated with making the repair or the cost of the repair may exceed the benefit of addressing a small leak.

Leak surveys are often useful to identify leaking components at a compressor station. There are various technologies available to detect methane leaks, such as EPA Method 21 or an optical gas imaging camera.

Controlled venting – A pipeline company may release gas at a compressor station when shutting down a compressor to conduct either planned or unplanned maintenance work, due to abnormal operations, or if the compressor is temporarily shut down due to low demand for natural gas.

These emissions are often commonly referred to as blowdowns. Isolation valves are closed, and a blowdown valve is opened when the compressor is taken off-line and depressurized. Pipeline companies maintain compressor station vent logs that record these events, which are reported to U.S. EPA in an annual facility report pursuant to the requirements in the U.S. EPA Greenhouse Gas Reporting Program.

When conducting maintenance or repairs at the compressor station, it is neither practical nor economical to install portable flares to combust residual gas once the operating pressure at the station has been reduced using existing or temporary compression.

Methane emissions from compressor stations are reduced through various measures, including: replacing rod packing on reciprocating compressors; conducting leak surveys to identify leaking components and taking corrective measures; and where practical, minimizing releases prior to conducting planned maintenance. INGAA member companies commit to minimizing emissions from natural gas transmission and storage compressor stations, where practical, prior to conducting planned maintenance.

INGAA member companies commit to minimizing methane emissions from rod packing seals on all reciprocating compressors at transmission and storage facilities. They agree to replace rod packing on all transmission and storage reciprocating compressors by using one of the following replacement options:

(1) a condition-based approach

(2) every 26,000 hours of operation

(3) 36 months from the date of the most recent rod packing replacement.

Pipeline Emissions

Venting – To maintain safe operations, natural gas may be released from pipelines to the atmosphere during operations such as maintenance, inspection, repair, replacement or emergency work. These releases from a pipeline segment are typically intentional releases that occur while depressurizing the pipeline.

For example, a pipeline operator may intentionally release gas from a pipeline segment to conduct integrity management testing to comply with pipeline safety regulations. The volume of emissions released during these activities depends on the pipeline’s internal volume, frequency of blowdown events, operating temperature, as well as pre- and post-blowdown pressures.

The ability to reduce pipeline pressure to minimize venting is limited by the pipeline configuration (i.e., single pipeline or multiple pipelines adjacent to each other), available compression (i.e., existing pipeline compression or temporary rental compression), the timeframe available to draw down the pressure, potential effects on customers, weather and other factors.

Pipeline operators cannot always control the timing and need for pipeline venting, such as in urgent repair situations when they must also maintain pipeline integrity and ensure safety. For these reasons, INGAA members have not committed to reducing pipeline venting (or blowdowns) by a certain percentage.

Instead, INGAA member companies are committed to decreasing such emissions to the extent reasonably practicable, taking safety and other factors into consideration.

Because these releases are required for reasons such as maintenance, inspections and other safety considerations, widespread replacement of interstate natural gas pipelines is not the answer to reduce methane emissions from the transmission sector (in contrast, such replacement may be necessary for the distribution sector).

Rather, various maintenance methods and technologies are available to minimize pipeline and storage venting to maintain pipeline integrity and minimize adverse customer impacts. For example, inline inspection (ILI) technologies that can measure the material strength of pipelines as effectively as, or better than, hydrostatic testing and can reduce methane emissions that would otherwise result from conducting hydrostatic testing as part of integrity management programs.

ILI technology involves running a sensor through the inside of the pipeline, while the natural gas is still flowing, to analyze the actual material condition of the pipe. This precise tool allows pipeline operators to identify specific pipeline sections that may require additional evaluation or repair, without needing to clear the natural gas from an entire pipeline segment to conduct a hydrotest.

When pipeline repairs need to be made, maintenance methods such as hot tapping or engineered sleeves may offer a safe and effective alternative to venting and removing the pipe.

Fugitive emissions/leaks – “Meter and pressure regulating stations are used in natural gas transmission to measure flow of gas at a custody transfer point, and/or to reduce and regulate pressure and flow into a downstream pipeline system.”

Metering and regulating stations are also located at points where natural gas is exchanged with other transmission companies or where they deliver gas to local distribution companies.

Various types of meters can be used to measure natural gas, including: orifice meters; turbine meters; ultrasonic meters; and positive displacement meters.

Fugitive emissions can occur from flanges and other connectors along pipelines and at metering and pressure regulating stations.

Incidents – While extremely rare, a natural gas pipeline may unintentionally release methane in the event of a “dig in” (a third-party “hit”) or another type of pipeline incident. A pipeline company may subsequently release natural gas intentionally to control the incident and protect the safety of the system, its employees, and the public in the affected area. Federal regulations issued by the U.S. Department of Transportation (DOT) require natural gas pipelines to report these incidents if the unintended gas loss is estimated to exceed three million cubic feet.

Opportunities to reduce emissions from pipelines – Operators can reduce methane emissions from natural gas pipelines by implementing practices that minimize releases during maintenance, repair or replacement, while also taking into consideration maintaining pipeline integrity, safe operations, and minimizing adverse effects on customers and communities.

To that end, INGAA member companies commit to evaluating and implementing voluntary practices, such as those found in the U.S. Environmental Protection Agency’s Natural Gas Star Program.

Members will address fugitive emissions from metering and pressure regulating stations through the commitment to conduct leak surveys at transmission and storage compressor stations. As noted above, INGAA member companies will survey all transmission and storage compressor stations, owned and operated by INGAA member companies by 2022.

Storage Emissions

Natural gas storage facilities are used to store natural gas that is produced during off-peak times so that it is available during periods of peak demand, such as in the winter.

Most natural gas is stored below-ground. Below-ground facilities compress and store the natural gas (as a gas, not a liquid) in one of several formations: (1) depleted gas production fields, (2) aquifers, or (3) salt caverns.

According to EPA, “underground storage is not a major source of methane emissions compared to emissions from natural gas transmission pipelines and compressor stations.” Fugitive emissions sources from natural gas storage include leaks from:

- Piping, valves, compressor seals, flanges, fittings, and other components

- Improperly plugged and abandoned wells

Natural gas storage facilities also have continuous and intermittent venting sources:

- Vents from pneumatic devices

- Compressor startup

- Compressor shutdown

- Gas dehydration

- Condensate storage tank venting

- Equipment depressurization

The methane emissions reduction strategies at storage facilities often include the methods discussed above for compressor stations and pneumatic devices.

According to U.S. EPA data, compressors and other facility leaks are the largest sources of emissions from natural gas storage facilities.

Therefore, the voluntary compressor station commitments that INGAA member companies have adopted apply to the compressor stations located at INGAA member companies’ natural gas storage facilities. P&GJ

Comments