December 2019, Vol. 246, No. 12

LDC Report

In Situ Pipeline Coating – A Hidden Champion Comes Out Of Hiding

By Michael Magerstaedt, Managing Partner, HiTeConsulting GmbH

In situ pipeline cleaning and coating offers advantages over conventional methods, particularly if it is possible to coat multi-mile lengths of pipe at a time. Not only rehabilitation of lines suffering from corrosion or deposits, but also in situ internal coating of new lines can offer savings as well as results of high quality and durability.

For about 40 years, a progressive cleaning and coating process has been practiced by EnerClear Services, a Canadian company specialized in this technology. Advantages besides the obvious avoidance of excavation cost are both the extremely good surface preparation of the pipe before internal epoxy coating and the surface of the internal coating which is much smoother than that of a similar coating applied by spraying.

For new pipelines, the need to leave cutbacks at both ends of each pipe joint for welding is eliminated. This does not only reduce cost significantly, the operator is now able to get a smooth continuous coating, whilst with factory coated pipes, there would either be a succession of uncoated field joints or field joints that are (expensively) coated after welding.

The latter will automatically mean that there is a lot of unevenness on the internal pipe surface. This leads to increased power consumption compared to a smooth surface as provided by the process. Hence, a smaller sized pump can be used saving a significant share of operating expenses.

Etching vs. Blasting

Conventional coatings (paints, epoxies and thermal spray) require the base metal to be blasted to NACE #2, or SSPC SP10 specification "near a white metal blast" prior to application of the coating material. Normally, this is achieved by grit blasting a process that is easily applied to single pipe joints at a pipe coating plant. For in-field applications, this is a lot more difficult.

Robotic systems exist that can perform internal grit blasting over some distance, a process that works well, particularly on large pipe diameters, but that is considerably expensive, especially on longer distances.

A study conducted in the winter of 2016 in Northern Alberta, Canada compared a grit-blasted carbon steel pipe to an identical carbon steel pipe, which was acid – etched by the EnerClear Process. The results show very similar surface structures.

|

Sample Type |

Surface Roughness |

|

Surface Area |

|

|

|

Testex Tape |

Laser Profilometry |

Scan Area |

Profiled Surface |

Area Increase |

|

|

blasted |

2.1 mil |

9.4 um RA |

5 mm x 5mm |

33.6 mm2 |

34% |

|

etched |

2.4 mil |

8.8 um RA |

5 mm x 5mm |

32.9 mm2 |

32% |

Table 1

|

Test Method |

blasted preparation |

sketched preparation |

|

ASTM 4541 Pull-Off Adhesion |

>1850 psi, 100% glue failure |

>2124 psi, 100% glue failure |

Table 2

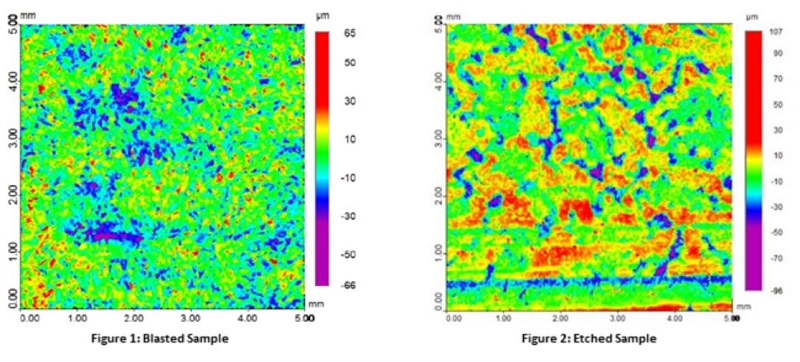

Figure 1 shows the laser profile generated by scanning the blasted sample. This data indicates that the blasting has gouged the steel to a maximum depth of 66 um, while displacing the steel to a maximum height of 65 um. The data indicates that the maximum variation between highest peak to lowest valley is 131 um.

Figure 2 shows the laser profile generated by scanning the etched sample. The maximum height measured from the artificial surface is +107um, while the maximum depth of the etching was measured at -96 um. The implication is that the maximum variation between the highest peak and lowest valley is 203 um.

In order to further confirm the analysis of preparation techniques, conventional adhesion tests were performed on etched and blasted substrates. Results of those tests appear in Table 2:

EnerClear's in-situ coating process, which follows surface preparation, uses a batch of epoxy coating applied under pressure between two bi-directional pigs. This process, repeated a defined number of times, assures complete coverage of the internal pipe surface including pits and weld seams.

Today, EnerClear has developed capabilities to roll out this process on a global scale. A combination of decades of experience on one hand with modern, AI/ machine-learning software that determines optimized process parameters for each new project makes this process reliable. – P&GJ

Chad Allan, Nathan Campbell and Chad Carriere contributed to this article.

Comments