October 2024, Vol. 251, No. 10

Tech Notes

Product Shows Potential for Deepwater Flowlines

Special to P&GJ

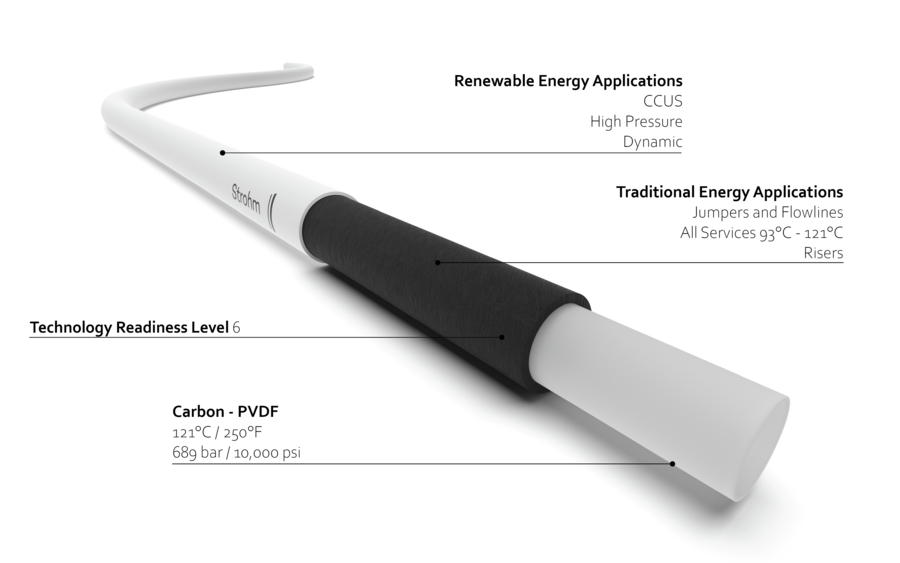

Strohm qualified its first product based on carbon fiber and advanced PVDF polymer.

By combining polyvinylidene fluoride (PVDF), a high-performance polymer, with carbon fiber, the company can offer jumpers and flowlines for use in harsh environment carbon capture and storage (CCS) applications.

With the addition this PVDF product, Strohm has now completed its materials portfolio for CCS, meaning it can call on the optimum material for each specific project.

As a corrosion-free solution, with a 30-year design life and a proven smaller carbon footprint compared to steel, it is suitable for injecting CO2 offshore, both in depleted gas fields and aquifers.

With a long track-record in oil and gas, PVDF is renowned for having a high chemical resistance and higher temperature capability.

It is different in that it is the only material of its kind strong enough to handle the high temperatures and high pressures associated with ultra-deepwater hydrocarbon production and provides a high level of natural insulation.

Besides its potential for high CO2 content transfer in CCS applications, Strohm’s new TCP product has the potential to be a significant change for the deepwater flowline and riser market in the offshore energy industry. It also concludes a major step in developing and qualifying TCP risers for use in challenging ultra-deepwater environments.

“One of our central pillars at Strohm is our drive to introduce disruptive technologies to the market, thereby doing our bit to help the transition move forward at pace – this is a clear-cut example of that ambition bearing fruit, said CEO Martin van Onna.

Comments