September 2024, Vol. 251, No. 9

Features

How Artificial Intelligence Will Transform Pipeline Construction

By Mark Bridgers and Kyle Kerestes, Consultants, and Pete Blonkvist, Business Analyst, Continuum Capital

Artificial Intelligence is all the rage. Nearly all of the discussion is how efficiently it can perform repetitive tasks, forecasting, etc. There are fears, as well, that AI will displace humans and their jobs.

The pipeline industry has long believed that physical pipeline construction work required such a high skill level and experience, it will be insulated from change…is this true any longer? Over the coming months, Continuum will profile 100 artificial intelligence (AI), machine learning (ML), and robotic innovations.

A famous Indian yoga teacher, B.K.S. Lyengar wrote, “Change is not something that we should fear. Rather, it is something that we should welcome. For without change, nothing in this world would ever grow or blossom.”

AI is the most powerful change that we will experience over the coming decade and firms that embrace it will have an opportunity to blossom. The pipeline construction industry and the construction industry in general have tended to be late adopters of innovation and technology...why…fear?

As Lyengar described, real opportunity only originates from change and the already underway AI driven transformation is an opportunity to embrace this change to compress schedule performance, drive down total cost, raise achievable profit and more.

As we enter the age of AI, pipeline operators, contractors, and designers have a new opportunity to embrace innovation, pursue waste reduction, and improve construction productivity…but how?

Introduction to AI

In order to understand AI, it is important to recognize the differences in these tools. While AI seems brand new, there is significant history beginning with English mathematician Alan Turing who theorized that a computer program could interact with humans in a way that humans could not differentiate between the computer and another human.

Today’s AI tools, in many instances, approach or meet this standard. To help organize the broad concept of AI, Continuum has divided tools into three categories:

- Artificial Intelligence – the ability of machines to sense, perceive, reason, engage and problem solve in a manner that seems intelligent.

- Machine Learning – enabling machines to learn, problem solve, and improve based on data or experience, without being explicitly programmed. Deep Learning is a subset of machine learning which uses multiple layers of data processing and analysis to mimic the neural structure of the human brain and allows for complex and multi-level experience based enhancement of performance over time.

- AI Enabled Robotics – AI or ML empowered robotics that are augmented with a variety of sensors (including vision devices such as 2D/3D cameras, LiDAR sensors, vibration sensors, proximity sensors, accelerometers, and other environmental sensors,) that feed them with sensing data they can analyze and act upon in real-time. A subset is “cobots” where a robot can respond to and learn from human speech and gestures without worker-assisted training.

The vast majority of conversation about the application and use of AI revolve around what Continuum refers to as “thinking” exercises – consider large database analysis, forecasting, contract writing or review, etc.

The ultimately more interesting and impactful assessment is how AI, ML and robotics will be applied to augment, not displace, the pipeline construction workforce in three ways:

- Production Increase (Output Expansion) - solutions allow crews to raise production and perform more work, safely and in compliance with specifications, in a given time period – offset part of workforce availability constraints.

- Individual/Crew Augmentation (Capable Workforce Expansion) – solutions increase the number of field staff or crews that can perform specific activities – larger number of people who can lift heavy equipment or materials, utilize complicated equipment, operate in confined space, etc.

- Accelerate Personal Performance (Average to Superior Performance) – solutions allow individual crew managers and crew members, with limited or average experience, to perform at a superior level – shorten the “on-the-job” experience gain time period, accessing expertise, etc.

The three applications above will lead to significant performance improvement by driving out the eight wastes (Exhibit 1).

Output Expansion

Is it possible to improve unit/parts installation 177%? The Pipeline construction segment is in a lower spending cycle while Gas Distribution remains relatively healthy and growing.

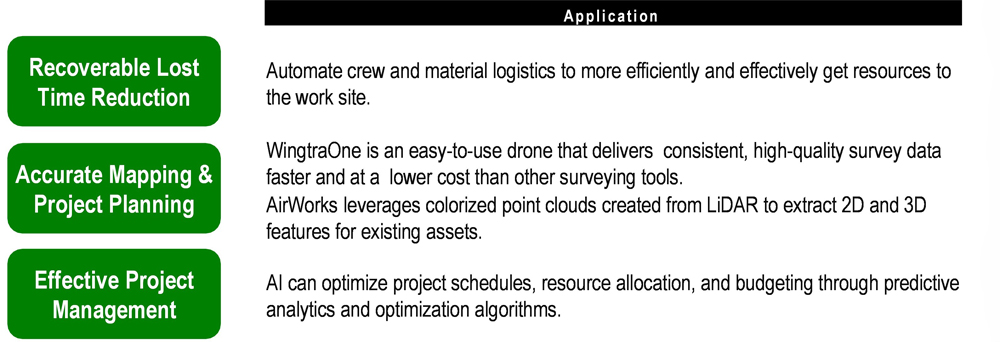

Historically and going forward their remains a workforce shortage that results in spending that is budgeted and planned for a given year and cannot occur until the following year. Solutions in this category allow crews to raise production and perform more work, safely and in compliance with specifications, in a given time period – offsetting part of workforce availability constraints. Yes, it is possible to improve unit/parts installation 177%. Examples include (Exhibit 2):

- Recoverable Lost Time Reduction – reduction in unneeded material touching or movement before install.

- Accurate Mapping & Project Planning – accurate crew placement and material laydown raises wrench time.

- Effective Project Management – detailed predictive analysis, resource allocation, and optimized crew size.

Crew Augmentation

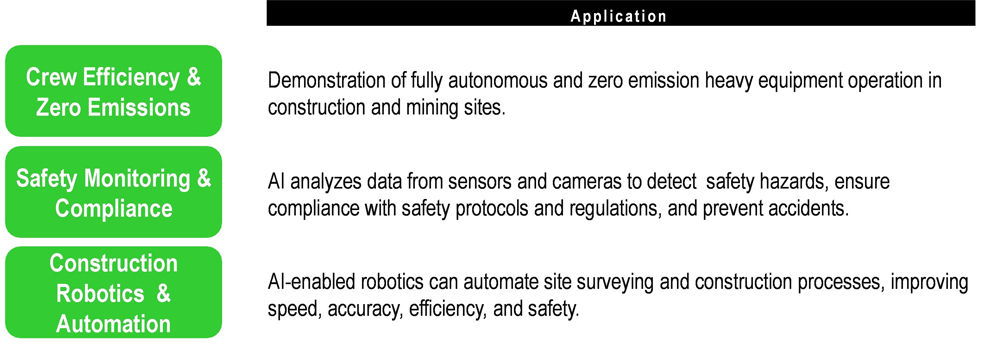

Is it possible to reduce rework percentage below 10%? The pipeline construction segment requires extensive training and ability to operate, lift, and utilize dangerous and heavy equipment, tools, and materials.

This requirement restricts the number of individuals and size of the workforce capable of performing this work. Solutions in this category increase the number of field staff or crews that can perform specific activities – larger number of people who can lift heavy equipment or materials, utilize complicated equipment, operate in confined space, etc. Yes, it is possible to reduce rework percentage below 10%.

Examples include (Exhibit 3):

- Crew Efficiency & Zero Emissions – expansion of workforce that can safely operate equipment.

- Safety Monitoring & Compliance – safety compliance raises production and reduces rework.

- Construction Robotics & Automation – automation, efficiency, and accuracy in time consuming or repetitive tasks.

Accelerate Performance

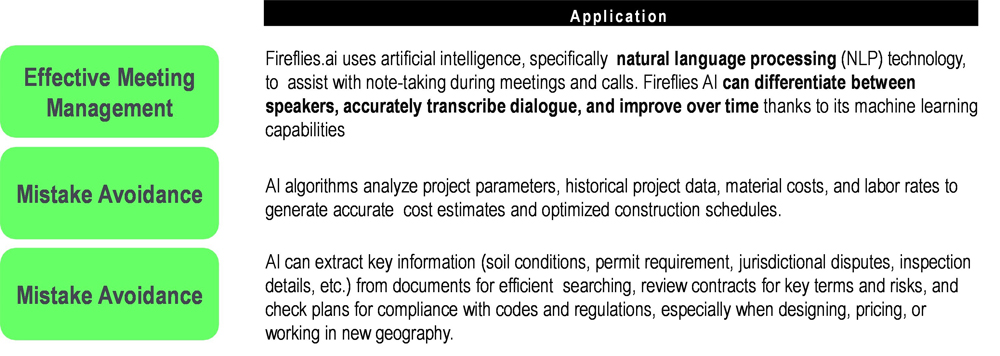

Is it possible to reduce schedule duration by 71%? Effectively shortening schedule duration is perhaps the hardest and most impactful type of change possible due to the cascading positive impacts. It is hard because it takes the most experience and capability to successfully do it.

The Pipeline construction segment faces the most challenging schedule requirements, crews are large, work is complicated and requires high coordination, the jobsite changes as work moves down the line, and planning is restricted by weather and other conditions. Solutions in this category allow individual crew managers and crew members with limited or average experience to perform at a superior level – shorten the “on-the-job” experience gain time period, accessing expertise, and shortening schedule.

Yes, it is possible reduce schedule duration by 71%. Examples include (Exhibit 4):

- Effective Meeting Management – documentation of agreements, actions, and next steps, all of which are shared efficiently raising the collaboration and coordination among the project team participants.

- Mistake Avoidance – algorithms analyze project parameters, historical project data, material costs, and labor rates to generate accurate cost estimates and optimized construction schedules.

Conclusion

The application of AI, ML, and Robotics to the construction space and more specifically into the pipeline market will serve as the most disruptive force over the next decade…true opportunity only originates from this type of disruption for firms that embrace it.

There is fear however…fear of change…fear of displacement…fear of job loss…fear of the unknown. B.K.S. Lyengar saw this fear of change as paralyzing and embracing it is critical to opportunity and growth. The introduction of AI is already occurring and to balance the fear, there is opportunity.

Over the last 20-plus years, average productivity improvement in the construction industry has stalled. When Continuum Capital conducts time and motion studies in the field, part of the effort is to document a baseline of performance; establish a plan and set of action for improvement; implement this plan and action; and then monitor improvement. In one example, improvement from the baseline achieved the following:

- Improved unit/parts installation rate 177%

- Reduced rework occurrences by 85%

- Reduce rework percentage below a target of 10%

- Reduced schedule duration by 71%?

The application of AI tools makes this type of production improvement possible by compressing schedule performance, driving down total cost, raising achievable profit, and more. Pipeline operators, contractors, and designers have a new opportunity to embrace innovation, pursue waste reduction, and improve construction productivity.

The time to embrace change is now. Over the coming months, Continuum will profile 100 artificial intelligence (AI), machine learning (ML), and robotic innovations to give your organization a running start. Embrace this AI change to grow and blossom.

Authors: Mark Bridgers, Pete Blonkvist and Kyle Kerestes are consultants with Continuum Capital, which provides management consulting, training, and investment banking services to the worldwide energy, utility, industrial and infrastructure construction industry. They can be reached at MBridgers@ContinuumCapital.net and connected with on LinkedIn at www.linkedin.com/in/mark-bridgers-0819b412/ and X (formerly Twitter) at @MarkBridgers. For more information on Continuum, follow at www.linkedin.com/company/continuum-capital or visit www.ContinuumCapital.net.

Comments