March 2025, Vol. 252, No. 3

Features

Tackling the Effect of Different Impurities in CCS Pipelines

By Alessandro Speranza, Michelle Wicmandy, Nick Flynn, KBC (A Yokogawa Company)

(P&GJ) — With rising global carbon dioxide (CO2) emissions and worldwide commitment to avoid environmental impacts, the contribution of Carbon Capture and Storage (CCS) technologies is crucial. Controlling impurities in CCS pipelines is key to this effort.

This article presents an analysis of how trace components in CO2 streams impact thermodynamic and transport properties, with potential long-term consequences on asset integrity. While the associated risks are highlighted, we focus on developing robust engineering solutions for large-scale implementation.

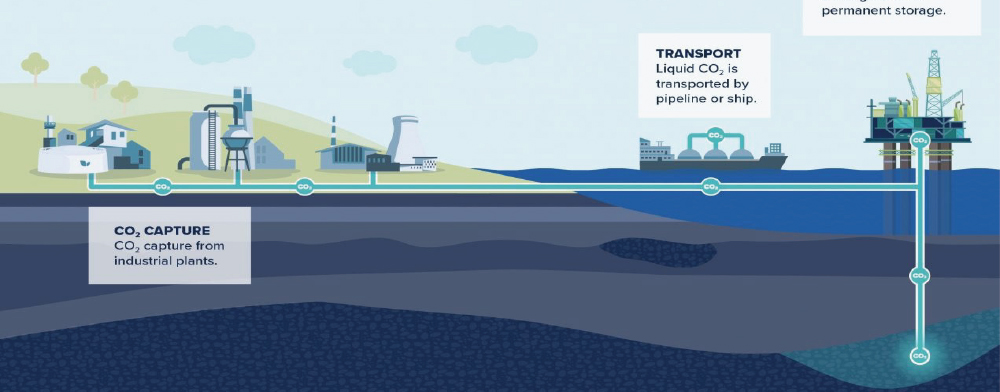

According to the International Energy Agency (IEA), “Carbon Capture and Storage (CCS) involves the capture of CO2 from large point sources, including power generation or industrial facilities that use either fossil fuels or biomass for fuel. The CO2 is then compressed and transported via pipelines, ships, rail or trucks to be used in a range of applications or injected into deep geological formations like depleted oil and gas reservoirs or saline formations for permanent storage.”

Figure 1 illustrates the CCS process that involves capturing CO2 emissions from sources like fossil fuel power plants or manufacturing plants and storing it to prevent it from entering the atmosphere.

CCS is a critical technology for emissions reduction and achieving Net Zero emissions, as it can significantly reduce greenhouse gas (GHG) emissions in hard-to-abate manufacturing sectors, such as cement, steel, chemical production and the oil and gas sector. Collectively, these industrial sectors contribute about 60% of global CO2 emissions, with oil and gas — refining in particular — accounting for approximately 42% of the total CO2 emissions.

The IEA estimates that CCS will need to contribute at least 15% of the total CO2 emissions reductions needed to achieve Net Zero by 2050. This underscores the importance of CCS in the global energy transition. No realistic scenario can achieve Net Zero by 2050 without the contribution of CCS.

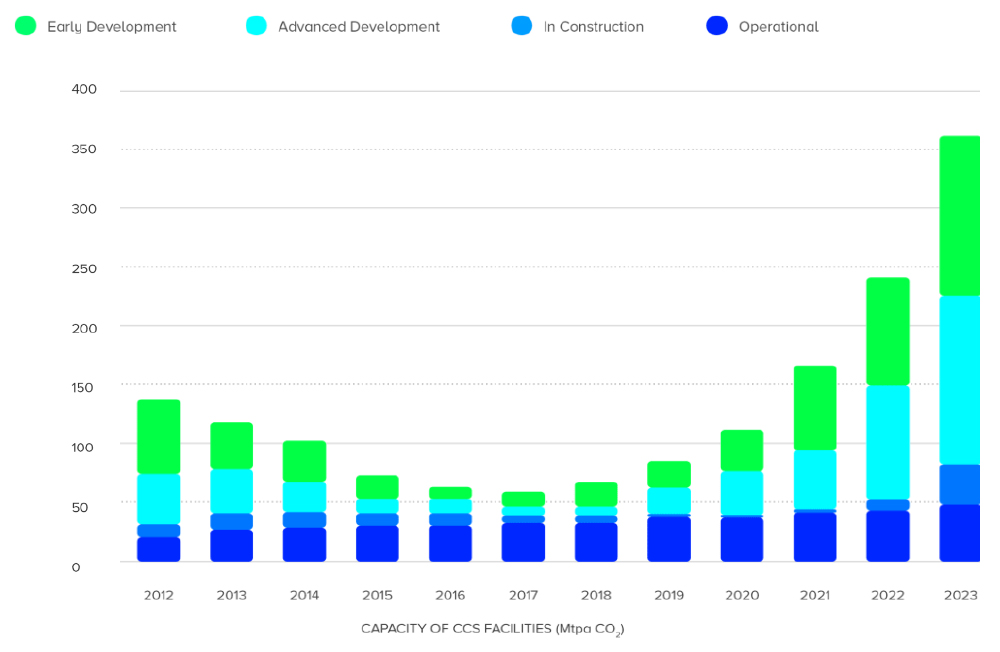

According to the Global CCS Institute, the CCS industry is rapidly developing, Fig. 2. In 2023, over 20 new carbon capture facilities were either under construction or commencing operations, capturing more than 350 Mtpa of CO2. This represents an increase of nearly 50% since 2022, highlighting the rapid growth and critical role of CCS in reducing emissions. A similar growth is expected for 2024 and 2025.

Understanding the Thermodynamic Behavior of CO2 Mixtures

Despite rising demand, CCS projects present unique technical and economic challenges. CO2 has unique thermodynamic properties, particularly related to its unusually high Joule-Thomson (JT) coefficient, which makes it difficult to manage during transport and storage.

This JT coefficient represents the rate at which a fluid cools down or heats upon expansion or compression. CO2 has a large, positive JT coefficient, which means it cools down when expanded or heats up when compressed — in both cases rapidly and by large amounts.

This is problematic during transport and storage. Rapid cooling can lead to thermal shocks in transport and injection facilities, such as pipelines and well tubings/casings, risking cracks and compromising infrastructure integrity. These risks increase in the project’s early stages, when highly compressed CO2 is injected into a low-pressure depleted reservoir.

Phase Behavior

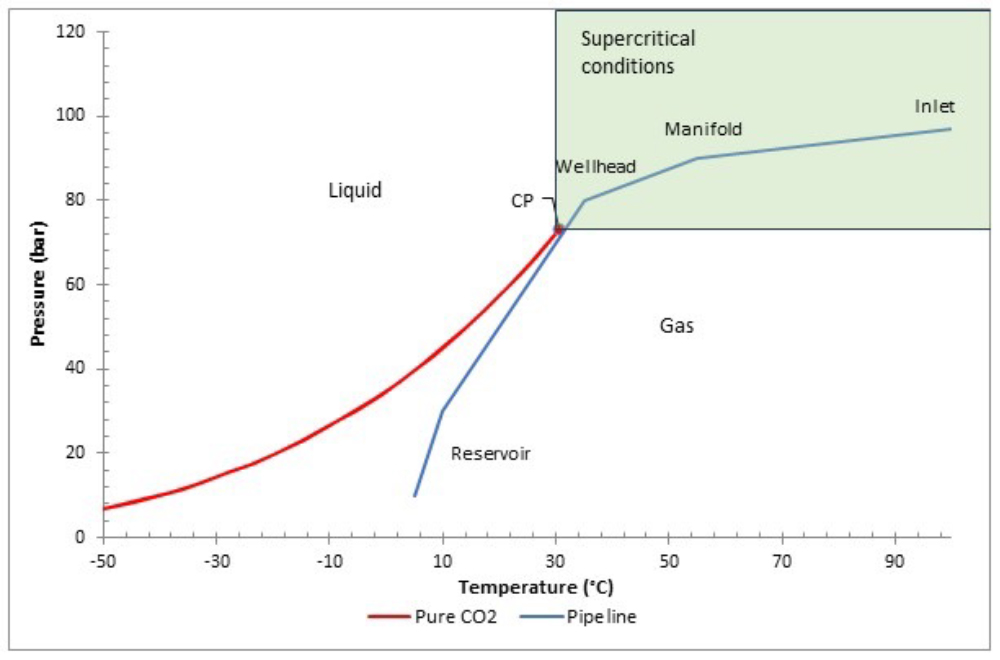

Another key challenge in CCS transport is related to its large variations in density and viscosity at different operating conditions. To avoid excessive pressure drops and maximize the mass flowrate, CO2 is transported in single phase — ideally at high pressure, in supercritical dense phase. This also allows for minimized risks of corrosion associated with liquid or aqueous phase drop-out.

However, maintaining the operating conditions in the supercritical range is challenging. As the CO2 is transported along the pipelines, its pressure and temperature drop rapidly (Fig. 3). When the fluid reaches the injection wellhead, it is likely to be in conditions nearing the critical point of CO2 (31.1°C and 73.8 bar).

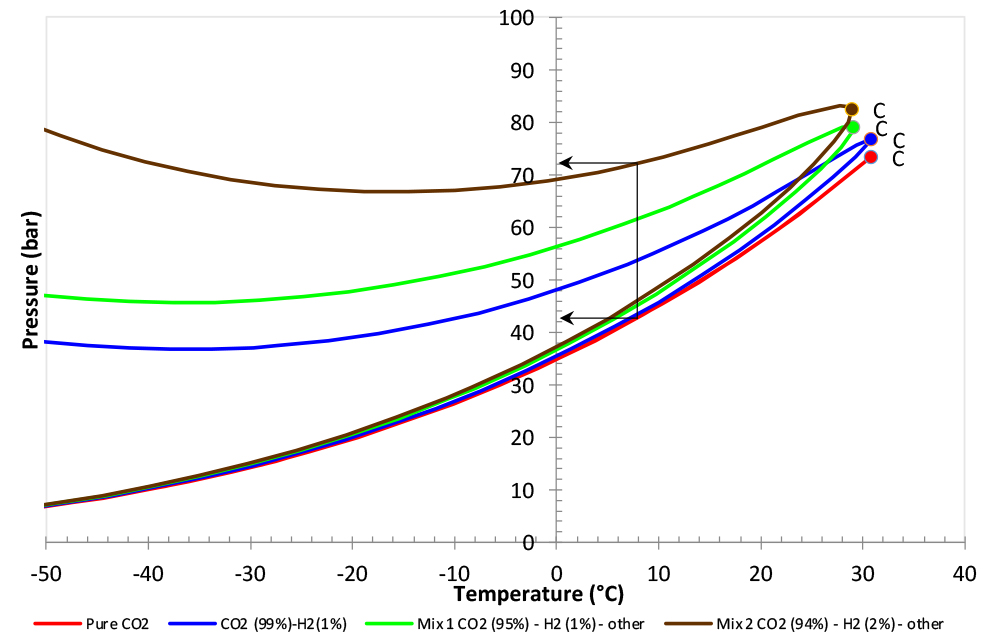

Initially, the injection well of a depleted reservoir is likely to be at an even, lower pressure (~10 bar or less). Therefore, during the expansion in the well, the fluid may transition to a liquid phase. In the presence of impurities, the 2-phase coexistence, represented by the red curve in Figure 3, expands to a 2-phase coexistence region (Fig. 4). The width of the curve is determined by the level of impurities.

In the expansion across the wellhead choke or along the tubing, the CO2 mixture cools further and is therefore likely to go through the 2-phase coexistence region (Fig. 4). This may cause liquid build-up in the wells, excessive cooling, corrosion or even blockages, due to the formation of solids (e.g., hydrates) in some extreme cases (e.g., when the CO2 mixture gets into contact with water forming in the reservoir).

As the reservoir fills up and the backpressure increases, operating conditions in the transport and injection facilities may approach the two-phase region earlier, causing liquid dropout in the transport lines. This situation may increase the friction, causing increased pressure-drop and requiring extra compression and energy to maintain the flowrate. Impurities in the CO2 mixtures play a crucial role in modifying the thermodynamic behavior of gas compared to pure CO2.

Impurities in the mixture modify the topology of the phase diagram. In a pure gas system two-phase, these can coexist only on a phase coexistence line in the Pressure and Temperature representation of the phase diagram. As the gas mixture becomes more complex, the phase coexistence line opens into a phase coexistence region, with different impurities affecting the bubble or dew point temperature in different ways.

Even small amounts of impurities can significantly shift the critical point and phase behavior of CO2, as shown in Figure 4. In particular, the presence of non-condensable gases, such as hydrogen and nitrogen, can alter the bubble and shift the critical pressure by several bars. Therefore, accurately predicting the thermodynamic behavior of the CO2 mixture is important for identifying and mitigating the associated risks.

The Joule-Thomson effect, where CO2 cools rapidly upon expansion, can intensify these risks. Fast expansion of CO2 containing impurities can cool to form liquid phases, causing blockages and pipeline damage. Additionally, water in the CO2 stream can cause the formation of hydrates, potentially obstructing flow and causing significant operational challenges.

Another significant risk is corrosion. Even small quantities of water in the CO2 stream can react to form carbonic acid, which is highly corrosive. This can degrade pipeline materials and increase leaks. Impurities such as sulfur compounds exacerbate corrosion, making dehydration of the CO2 stream essential.

For this reason, CCS mixtures are dehydrated to a very high-standard (~ppm) and controlled along the supply chain. Nonetheless, a small presence of some impurities, such alcohols or glycols — often present in the mixture — may cause the formation of small pools of liquid or aqueous phase, which can obstruct the flow or increase the risk of corrosion. This may be particularly critical in areas where the flow slows down: for instance, in low points of the pipeline or elbows and bends.

To mitigate the risks associated with these complex behaviors, accurate thermodynamic predictions are needed to develop effective engineering and operating solutions.

Optimizing CCS Transport

Integrated Asset Modelling (IAM) integrates surface facilities and subsurface reservoirs to provide a holistic view of the asset. This approach is used in oil and gas applications for field planning and long-term forecasting. However, the thermodynamic complexity of CO2 and the tight hydraulic coupling between the storage site and transport facilities make IAM a key element to evaluate operating scenarios and design solutions.

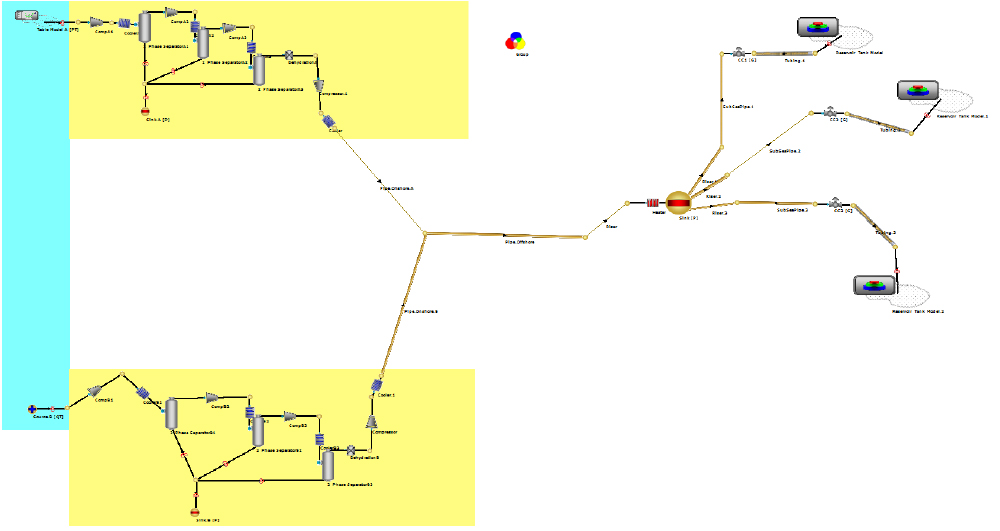

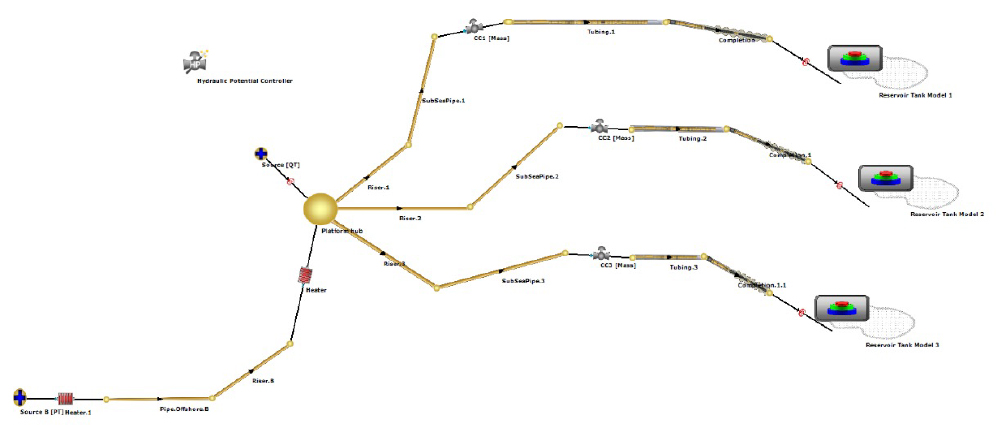

Figure 5 shows IAM of a CCS transport and injection facility, including compression, dehydration, subsea pipeline transportation and injection in offshore depleted reservoirs. This integrated approach allows users to simulate various scenarios over the life of the field, to evaluate changes in reservoirs and in capture and transport facilities, including different impurity concentrations, to predict impacts on flow and transport conditions. This helps identify risks and optimize operations.

Given the highly non-ideal thermodynamic behavior of CO2, in CCS, compositional simulations are required to distinguish the effects of compositional changes over time and their impact on the technical and economic feasibility. Black oil and table-based simulations — often used in oil and gas production — will be insufficient for CCS applications. By adjusting operating parameters and engineering choices, IAM helps design transport strategies that minimize the risk of phase changes and maintain efficient flow.

Transport Strategies

IAM is a powerful tool for managing the complexities of CO2 transport in CCS projects, particularly when dealing with different impurity concentrations. Using compositional simulations, IAM precisely models phase behavior and fluid properties across different pressure and temperatures.

Sensitivity analyses identify critical impurity thresholds that could lead to operational issues, while scenario planning enables engineers to design robust transport strategies capable of handling a range of potential feed compositions. IAM’s optimization capabilities allow engineers to determine the optimal pressure and temperature conditions for transport, considering the specific impurity profile of the CO2 stream, which is crucial for maintaining single-phase flow and avoiding issues like liquid dropout or hydrate formation.

Risk assessment is another key feature of IAM, modeling the impact of impurities on corrosion rates, material degradation, and other risks to guide mitigation strategies and select materials for construction. From an economic perspective, IAM assesses the impact of different purification levels, balancing the costs of impurity removal against potential operational and maintenance costs associated with transporting CO2 with higher impurity levels. The time-based simulation capabilities of IAM allow for modeling how changes in impurity concentrations over time affect the transport system, enabling adaptive management strategies.

By modeling the entire CCS chain, IAM helps engineers evaluate how variations in the composition in the capture phase may impact the transport phase and the storage processes downstream, ensuring a holistic approach to impurity and risks management. These capabilities empower engineers to design efficient, resilient transport strategies that optimize the performance and longevity of CCS infrastructure.

Case Study

In the case study, the effect on a CCS transport and injection network is modeled and simulated when an additional source of CO2 is introduced, as depicted in Figure 6. Alongside existing emitters, representing a refinery and a fertilizer plant operating at a fixed flow rate, we add a storage facility that collects CCS gas mixtures transported to the storage tank via shipping. This source is located at the offshore hub and distributes CCS gas mixtures to the three offshore storing facilities in depleted gas reservoirs.

The IAM simulation shows that by adjusting the pressure and temperature, the system can be maintained in single-phase flow, preventing liquid dropout and ensuring efficient transport. Adding CO2 via shipping impacts the overall flow rates and balance of the network, with potential capacity shortages in the transport and injection facilities as the turndown increases.

In this case, from a thermodynamic perspective, the additional CO2 source has higher purity, with a higher concentration of CO2. This affects the overall composition of the CO2 transported stream. This change in composition can shift the critical points and phase behavior, requiring adjustments to the operational parameters to maintain a single-phase flow.

The IAM simulation demonstrates that increasing pressure and adjusting the temperature prevents liquid dropout and maintains efficient transport across the entire network. The simulation also shows that the addition of the CCS mixture from shipping can increase the overall flow rate, but this must be balanced against the capacity of the transport and injection facilities. Continuous monitoring and adjustment of the operational parameters are essential to ensure the project’s feasibility and efficiency.

Transport with IAM

IAM provides a comprehensive approach to managing the complexities of CO2 transport in CCS projects. By integrating surface and subsurface modelling, IAM helps identify and mitigate risks associated with impurities and modifications of the operating conditions and layout of the project, with additional sources and modifications of the storage sites.

This integrated modelling approach enables the design of robust transport strategies that ensure the integrity and efficiency of the CCS asset over its lifecycle. However, continuous monitoring and adjustment of operational parameters are essential to adapt to the dynamic conditions of CO2 transport.

The ability of the integrated model to simulate various scenarios and predict the impact of different impurity concentrations allows engineers to design transport strategies that minimize risks and optimize performance. By maintaining a single-phase flow and preventing issues such as liquid dropout, hydrate formation, and corrosion, IAM ensures the long-term sustainability and economic viability of CCS projects.

Conclusion

Managing impurities in CCS pipelines is a critical aspect of ensuring the efficiency, safety, and long-term viability of CCS projects.

Through exploring this topic, the following key points emerge:

Impurity Impact - Even small amounts of impurities can significantly alter the thermodynamic behavior of CO2, affecting critical points, phase boundaries and transport properties. This emphasizes the need for precise compositional control and monitoring in CCS systems.

Thermodynamic Complexity - The unique properties of CO2, particularly its high JT coefficient and complex phase behavior, complicate optimal transport conditions. Managing these properties is crucial for efficient and safe CCS operations.

Risk Mitigation - Impurities increase risks like corrosion, hydrate formation, and phase changes. Risk assessment and mitigation strategies are essential for the long-term integrity of CCS infrastructure.

Integrated Modeling Approach - IAM offers a holistic approach to manage the complexities of CO2 transport, enabling engineers to optimize operations, predict issues and design robust transport strategies.

Adaptive Management Given the dynamic nature of CCS projects and potential variations in CO2 sources and impurity profiles over time, adaptive management strategies supported by continuous monitoring and modeling are crucial.

Economic Considerations - Managing impurities has significant economic implications, affecting both capital and operational expenses. Balancing purification costs against potential operational issues is a key consideration in CCS project planning.

Technological Advancement Continued innovation in impurity removal, materials science, and modeling techniques will be needed to improve the efficiency of and reduce the costs for CCS systems.

While impurities in CCS pipelines present significant challenges, they are not insurmountable. Through careful engineering, advanced modeling techniques, and a thorough understanding of CO2 behavior, these challenges can be effectively managed. Implementing IAM offers practical benefits, such as reducing operational risks, minimizing costly shutdowns and ensuring compliance with safety and environmental standards.

As the CCS industry continues to grow and evolve, the lessons learned and technologies developed in managing impurities will play a crucial role in realizing the full potential of CCS as a key strategy in global emissions reduction efforts.

References:

Beck, C., Rashidbeigi, S., Roelofsen, O., & Speelman, E. (2020, January 7). The future of oil and gas is now: How companies can decarbonize | McKinsey. Www.mckinsey.com. https://www.mckinsey.com/industries/oil-and-gas/our-insights/the-future-is-now-how-oil-and-gas-companies-can-decarbonize

Carbon Capture, Utilisation and Storage - Energy System. (n.d.). International Energy Agency; International Energy Agency. https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage

Global Status of CCS 2023 - Report & Executive Summary. (2023, November 9). Global CCS Institute; Global CCS Institute. https://www.globalccsinstitute.com/resources/publications-reports-research/global-status-of-ccs-2023-executive-summary/

IEA. (2020). CCUS in the transition to net-zero emissions – CCUS in Clean Energy Transitions – Analysis. IEA. https://www.iea.org/reports/ccus-in-clean-energy-transitions/ccus-in-the-transition-to-net-zero-emissions

Jones, C., & Piebalgs, A. (2022, January 12). The role of CCUS on the EU road to climate neutrality. Fsr.eui.eu; European University Institute. https://fsr.eui.eu/publications/?handle=1814/73595

Eduardo Luna-Ortiz (Trondheim Conference on CO2 Capture, Transport and Storage – Trondheim, Norway – June 21-23, 2021). ‘Co2cktails in a Pipeline’: The Phase Behaviour ofCO2 with >20 Impurities. https://sintef.brage.unit.no/sintef-xmlui/bitstream/handle/11250/2780236/Co2cktails%20In%20A%20Pipeline.pdf?sequence=1

Comments