May 2025, Vol. 252, No. 5

Features

How Filtration Adds Value in CCUS Systems

By Colm Joy, Chief Technical Officer, Cleanova

(P&GJ) — Decarbonization of industrial activities is key to mitigating climate change. From power generation to transportation to food production, there is a clear imperative to reduce the amount of carbon dioxide (CO2) entering the atmosphere. Techniques for separating CO2 from gas streams are well-established, but the sustainability imperative is raising new challenges for everyone involved.

The scale of the decarbonization challenge is daunting. Countries around the world signed the Paris Agreement in 2015, committing to limit global temperature rise to well below 2° C above pre-industrial levels1. Achieving this target requires aggressive decarbonization efforts. Estimates suggest that between 350 and 1,200 gigatons (Gt) of CO2 will need to be captured and stored this century.

Currently, about 40 megatons (Mt) of CO2 are captured and stored annually, so capacity must increase at least 100-fold by 2050, to meet the necessary targets2. Development and deployment of carbon capture, utilization and storage (CCUS) technologies at scale is therefore a key imperative.

CCUS encompasses a suite of technologies designed to capture CO2 emissions from point sources such as power plants and industrial facilities, preventing their release into the atmosphere. The captured CO2 can then be processed for storage underground or repurposed for industrial use. Whatever the final application, filtration plays a critical role at every stage — from initial capture to compression, transportation and storage or reuse.

Storage or Utilization?

Arguably, the biggest question for society is what to do with all that carbon once we capture it. As any filtration expert will tell you, the desired outcome is what drives effective system design.

The practical challenges of permanent CO2 storage are considerable. Identifying and assessing potential storage sites can be time-consuming and expensive. Where appropriate geological sites are identified, they may need to be adapted and monitored continuously. This includes installations using significant volumes of CO2 injected underground, as part of conventional EOR (enhanced oil recovery) operations. That said, proximity to suitable sequestration locations is likely the biggest global impediment to CO2 storage. Transportation distances can range from considerable to impractical. Building, monitoring and maintaining the necessary infrastructure adds significant costs3. For carbon capture to become viable at scale, storage is unlikely to present the most economical or practical long-term solution.

Utilization can be a better option. Applying circular economy principles and reusing CO2 in other industrial processes clearly supports the spirit and intent of the Paris Agreement by making CCUS more sustainable.

Plus, there are established markets for CO2, including carbonated drinks, food packaging and fire suppression, as well as emerging markets, such as the production of eFuels. Crucially, this means that captured CO2 becomes a value stream rather than a financial burden for carbon-intensive industries4.

Whether you are designing a carbon capture system with an aim of storage or utilization, the quality of the captured CO2 is critical for success, and this is where filtration comes into its own. Filtration not only removes contaminants to deliver the desired final product quality, but it also protects processing equipment and improves operational efficiency.

Let’s examine in more detail how filtration is applied in the distinct phases of carbon capture, as defined by the National Energy Technology Laboratory (NETL)5.

Filtration During Capture

CCUS projects primarily focus on capturing CO2 emissions from point sources. It is currently more cost-effective to capture the gas directly from concentrated exhaust streams rather than from the ambient air. Correctly applied, filtration maintains carbon capture system efficiency and delivers the CO2 to downstream processes with minimal contamination.

- Post-combustion filtration

Chemical absorption is the most mature technology for post-combustion capture. This process uses solvents, such as amines, to selectively absorb CO2 from the flue gas. It is commonly deployed in power plants, cement production, and other industries that burn hydrocarbons to produce energy. The CO2-laden solvent is heated to release the captured CO2, which is then compressed for transportation or storage.

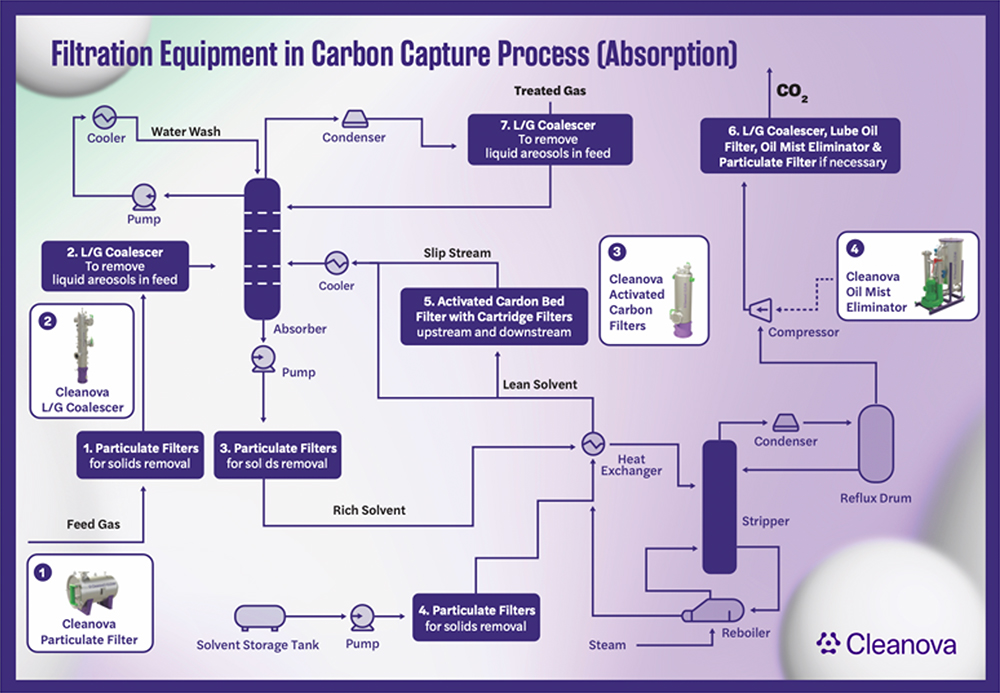

Figure 1 illustrates the primary points where filtration should be applied in a solvent absorption system. It is important to prevent any contamination reaching the top of the absorber column, because it will directly impact the quality of the CO2 and may lead to inefficient CO2 capture. High-capacity particulate filters are applied to remove contaminants from both feed gas and downsteam processes.

Coalescers protect the solvent from impurities in the flue gas that can cause fouling, foaming and solvent degradation: phenomena that result in a lower per-unit CO2 capture rate and exhausted CO2 escaping into the atmosphere. Activated carbon filtration is important in removing residual organics and hydrocarbons, for many of the same reasons. Oil mist eliminators ensure that only clean and oil-free air is exhausted by rotating equipment, in compliance with air quality standards.

Figure 1: Filtration equipment in the absorption carbon capture process

- Pre-combustion capture

Carbon dioxide can also be separated from the fuel before combustion occurs, using the pre-combustion capture method. This technique is commonly used in integrated gasification combined cycle (IGCC) plants, where fossil fuels are converted into syngas (a mixture of carbon monoxide, hydrogen and CO2).

The carbon monoxide reacts with steam in a process known as the phase shift reaction, which increases the concentration of hydrogen and CO2 in the gas mixture. The CO2 is then separated, allowing the hydrogen to be used as a clean fuel.

Pre-combustion capture requires filtration to remove impurities, such as sulphur compounds, particulates and moisture, from the syngas before CO2 separation. Membrane technologies, pressure swing adsorption (PSA), and solid sorbents are often used for CO2 removal in pre-combustion systems.

- Oxy-combustion capture

Oxy-combustion involves burning fossil fuels in an environment of pure oxygen (O2) instead of air. This reduces the presence of nitrogen in the flue gas, leaving primarily CO2 and water vapor as combustion byproducts. The water vapor can be easily condensed, leaving a highly concentrated stream of CO2.

The key component of an oxy-combustion system is the air separation unit (ASU), which generates the pure oxygen required. Filters are essential for removing impurities from the incoming air to protect the ASU and ensure efficient oxygen production.

- Direct air capture

Direct air capture (DAC) is a relatively new technique. This non-combustion form of carbon capture enables CO2 to be removed directly from atmospheric air. Solid DAC relies on sorbent materials with an affinity towards CO2 and uses a cycle system of adsorption and desorption. Liquid DAC uses solvents in a process based on absorption and regeneration loops.

The similarities between DAC and conventional carbon capture methods facilitate the transfer of existing filtration technologies into DAC processes, for filtering the incoming air, maintaining solvent purity and removing residual liquids before the air is released back into the atmosphere.

“Supercritical” Phase

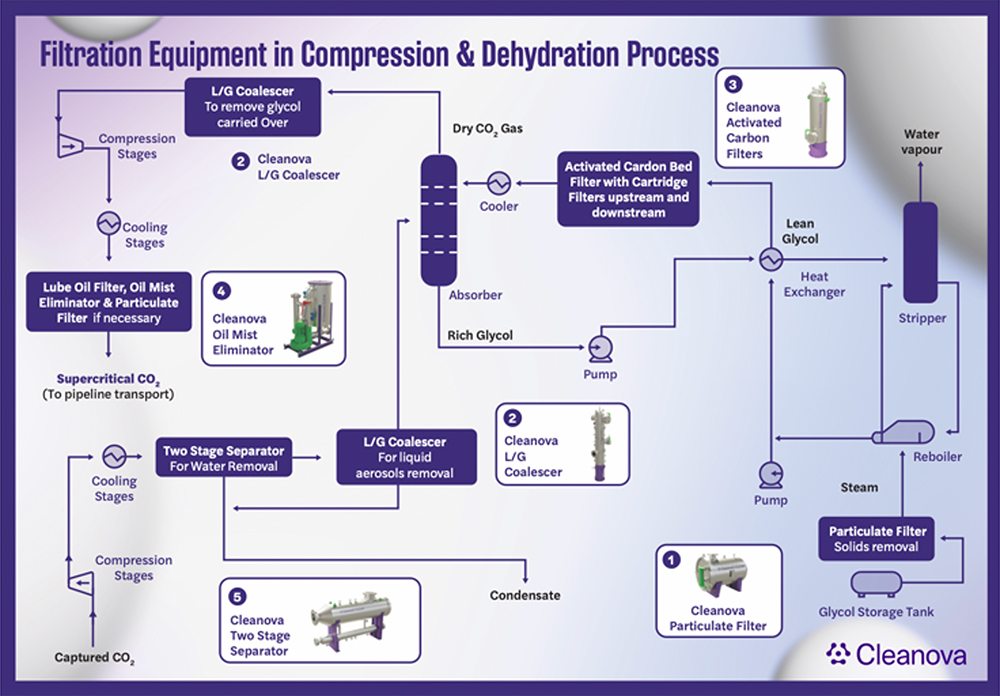

After CO2 has been captured, it is dehydrated and compressed to high pressure for transport and storage. This is known as the “Supercritical” or “Dense Phase” state. Filtration is essential for efficiency and safety during this process.

Contaminants, such as water, lube oil, oxygen and hydrogen sulphide (H₂S) present in the CO2, can threaten pipeline integrity by causing corrosion or pipeline blockages. Solid corrosion products and pipe scale can also be carried downstream, fouling critical equipment such as control valves, metering stations and high-pressure injection pumps.

This increases maintenance costs and can involve equipment replacement or unscheduled downtime. Solid contaminants can also plug permeable storage reservoir pore structures, requiring increased energy for CO2 injection and limiting the amount of available reservoir storage capacity.

Figure 2 illustrates where filtration should be applied during the supercritical phase. In selecting filters and separators for dense phase CO2 applications, substantial care must be taken over which materials are used, how filter sizing is performed and the correct filtration rating. To protect reservoirs, the filter rating must be selected based on the reservoir permeability and approximate pore diameter.

Advances in CCUS Filtration

While on a rapid development track, the CCUS sector is far from mature and focused primarily on finding new CCUS technologies and materials. The challenge for filtration specialists is to leverage the proven benefits of technologies that have been used reliably for many years in conventional natural gas applications and redesign these to meet the requirements of CCUS applications.

Cleanova’s UNIQ-MAX filter technology has been developed to address the problems that arise in absorption-based CCUS systems where high levels of particulate contaminants can impede the effectiveness of the amine and lead to clogging of downstream process equipment. UNIQ-MAX filters provide a market-leading solid removal capacity per unit area and are configurable across a wide range of filtration efficiencies (1–100µ).

The technology is absolute rated and tailored to protect a range of physical solvent processes, including monoethanolamine and diethanolamine (MEA/DEA), Selexo and Purisol, which are currently gaining traction for pre-combustion carbon capture. In parallel, UNIQ-MAX filtration is highly effective in high pressure supercritical CO2 injection applications where low particle concentrations are critical to the efficient sequestration of the gas in depleted rock formations.

But better filtration equipment alone will not solve the challenges of decarbonizing industrial processes using CCUS. No “standard” design for CCUS exists, and each application will have unique process challenges. Identifying the best filtration solution therefore requires system designers and filtration experts to work together in a new way.

Cleanova.C-CLEAN provides tailored filtration solutions designed for each carbon capture process, based on the chosen method, load quantities, type of contaminants, CO2 concentration, pressure and temperature. The aim is to collaborate with CCUS operators from the earliest concept stages, because considering filtration requirements from the outset, and within the context of the entire system design and business model, will yield the best results.

Last Word

The successful adaptation of existing technologies, such as filtration, to meet the specific requirements of CCUS operations is an ongoing process, and early collaboration is crucial to the success of our decarbonization journey.

This article is based on the whitepaper “Carbon capture, utilization and storage: a filtration perspective”, which can be downloaded here: https://www.cleanova.com/ccuswhitepaper/

References

Comments