September 2010 Vol. 237 No. 9

What's New

New Products: September 2010

Descriptions and details of new products offered from Burckhardt Compression, Bishop Lifting Products, TechCorr, Sick Maihak, Inc., CRC-Evans, Flowserve, Lincoln Electric, R&M Energy Systems, BFX Equity Partners, Dresser Pipeline Solutions, Hammersmith Mfg., Flow Management Devices, American Public Gas Association, Sullair Corporation and Huntingdon Fusion Techniques.

Burckhardt Compression

Burckhardt Compression has announced that, due to the unique labyrinth sealing technology of its Laby®-GI compressor and its small footprint, Burckhardt Compression has been awarded an order by TS LNG BV to deliver a Laby®-GI Booster Compressor for the Gate LNG import terminal in Rotterdam-Maasvlakte, The Netherlands. The order is for additional high-pressure compression within the existing LNG import terminal. The responsible contractor for the order is TS LNG BV composed of Techint, Italy, and SENER, Spain.

The compressor will feed the natural gas into the pipeline with 83 bar pressure. The compressor has a unique labyrinth sealing system on piston and piston rod gland that allows oil-free and contact-free compression for minimum wear and tear. On top, due to limited space TS LNG BV preferred the compact vertical design of the Laby®-GI Compressor. Delivery is scheduled to be in Q2 2011. 41-(0)52-262-55 00, www.burckhardtcompression.com.

Bishop Lifting Products

Bishop Lifting Products, Inc. announced completion of construction of its 3.3-million-pound (1,500-metric-ton) proof tester. With an overall length of 323 feet, and an inside pulling length of around 275 feet, it is said to be the most technically advanced proof tester built. Designed and fabricated by Chant Engineering and Bishop Lifting, it is termed a first-of-a-kind 3-in-1 testing machine for proof testing slings, crane blocks, spreader bars, oilfield equipment and rigging gear. David Bishop, CEO, managed the testing equipment expansion project. Pictured: Randy Brown (left), Mike Davenport, Harold King, Jeff Bishop, Phil Chant and David Bishop. 713-674-2266, 800-972-1041, sales@lifting.com, www.lifting.com.

TechCorr

TechCorr’s SpiderWrap® is for such pipe wrap uses as reinforcement, corrosion protection, abrasion protection, impact protection, and – in certain instances – leak repair. It is a water-activated, resin-impregnated fiberglass fabric, made in varying lengths and widths to accommodate all pipe sizes and wall thicknesses. It is nontoxic, easy to apply and suitable for a variety of pipeline applications. The company says it is a fast, efficient, economical, easy-to-use alternative to any other repair product or replacement. In most applications, the need for pressure reduction is minimized and downtime is eliminated. 713-524-2768, 877-562-0912, www.techcorr.com.

Sick Maihak, Inc.

Sick Maihak offers a 12-page brochure “FLOWSIC600 Ultrasonic Gas Flow Meter For Custody Transfer and Process Applications.” The company says that its many years of experience and continuous improvement of the measuring technique have led to a new generation of ultrasonic gas flow meters. The brochure says the new 2-48-inch, ANSI 150…2500 meter’s compact design uses a patented concealed transducer cable system that provides added meter integrity and low maintenance. The meter can be equipped with up to eight non-reflective, chordal measuring paths. It offers integrated real-time meter health monitoring with user programming of diagnostics and three logbooks (alarms, warnings and parameter changes). 281-436-5100, information@sick.com, www.flowsic600.com.

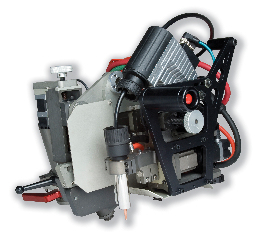

CRC-Evans Automatic Welding

CRC-Evans announces that it has integrated CMT (cold metal transfer) technology with its P450 automatic welding machine, creating new parameters of quality and speed for work on small-diameter pipe. This exclusive equipment offers advanced capabilities that make a significant difference in productivity for offshore projects. The CMT robotic technology controls all functions digitally with advanced software that instantly processes welding data. Equipped with continuous digital feedback, CMT boosts response time for the power supply and executes precise control of the AC servo wire feed motor. 5G and 2G root bead passes are completed rapidly and perfectly. No copper backup clamp is required. The company terms the technology as being “game-changing for small-diameter offshore and spoolbase pipeline operations.” 832-249-3100, www.crc-evans.com.

Flowserve Corp.

Flowserve Corp., a provider of flow control products and services, has introduced the Flowserve Worcester Series 608 three-piece ball valve, which is said to provide high-cycle life, durability and increased plant uptime for customers in the oil sands industry. “Worcester Series 608 valves offer extended service life and superior seat and seal design, which reduce total cost of ownership and help increase plant uptime,” said Brian Hood, Product Manager, Flowserve Flow Control Division. The valves feature an optimized stem design and live-loaded stem seals, which meet the requirements of API 608 and increase mean time between failures (MTBF). The Worcester flexible lip-seat design provides extended cycle life. 800-225-6989, www.flowserve.com.

Lincoln Electric

Lincoln Electric has introduced new Pipeliner® 80Ni1 MIG (GMAW) wire to its line of Pipeliner consumables developed to meet the rigorous demands of the global pipe welding industry. It is designed for semi-automatic or automatic welding of root, hot, fill and cap passes on up to X80 grade pipe and root passes on up to X100 grade pipe. It is said to be capable of producing impact properties of 69–95 J at -50°C (-58°F) to meet the demands of tough pipeline jobs. This new wire increases productivity with enhanced arc characteristics and provides optimal wire placement for narrow groove joint configurations. All Pipeliner® products feature ProTech® foil bag packaging to ensure reliable performance and are manufactured to lot control standards and tested per AWS A5.01, Class S4 Schedule H. www.lincolnelectric.com. www.lincolnelectric.com, Bulletin C1.100.4.

R&M Energy Systems

R&M Energy Systems offers its latest, most technically advanced solution for pipeline and vessel closures. Marketed under the SENTRY® brand name, the non-threaded, internal door closure features an innovative one-piece seal that provides many features and benefits not available in other closure types. Some features include: 1) molded in all sizes with no vulcanized splices, 2) available in FKM (Viton), EDR FKM (Viton) or HNBR low temperature materials, 3) installation of the one-piece replacement seal is quicker and easier, and 4) an anti-extrusion spring is molded into the seal. All pressure-retaining components are manufactured from ASME SA-designated materials. An improved hinge arrangement and a unique means of holding the locking segments in the open position make closure operation smooth. 403-264-2995, 936-890-1064, E-mail: fmg.marketing@robn.com.

BFX Equity Partners, LLC

BFX Equity announced its assimilation of natural gas leaders in fabrication, midstream and gas processing. The firm says it provides a single source for all oil and natural gas operations related to ASME manufacturing, gathering, treating, gas processing and transport, as well as plant acquisition and refurbishing. Its subsidiary companies are BFX Fabrication, BFX Midstream and BFX Process. BFX Fabrication manufactures ASME code vessels for gas processing and gathering companies as well as noise abatement acoustical panels. BFX Midstream is a team of design, construction and operations veterans for projects that require moving gas or oil to market. BFX Process is a source for refurbished plants and all aspects of removal, installation and repair of processing and treating vessels. J.W. Varner, 469-916-5775, www.bfxco.com.

Dresser Pipeline Solutions

Dresser® announced the availability of its new Piping Specialties Style 220 low-profile repair sleeve. This sleeve is the result of what the company terms its unique manufacturing capabilities combined with an existing product, creating a repair solution that reduces labor and material costs in the field. The new sleeve can be used on gas and liquid transmission pipeline repairs, allowing for full encirclement repair over past repairs or pipeline damage. Its innovative design replaces the wedding band oversleeve design, requiring 10 welds, with the Style 220 low profile sleeve requiring only four welds. This new sleeve does not require backing strips under longitudinal seams. With only two halves requiring four welds, crews can install three times the number of repair sleeves per day, when compared to other repair methods. Jolie Onuffer, 877-704-3737, www.dresser.com.

Hammersmith Mfg.

Hammersmith Mfg. introduces The FlexxRight Mini, described as a new, dynamic and patent-pending excavation bucket for the pipeline and utility location and inspection, excavation and site prep industry. The excavation bucket is described as flexible, safe and strong. It is targeted at compact and mini-excavators weighing 6 metric tons or less, the bucket is available in an 18-inch diameter size. It is described as a flexible bucket with a penetrating profile, a non-marking body design, tremendous strength and service, exceptional maneuverability and a universal coupling system. Excavate and locate safely and with ease. Eliminate expensive damage, reduce costs and dig safer. http://www.flexxright.com, http://www.hammersmithmfg.com.

Flow Management Devices

Flow Management Devices (Flow MD) is rapidly expanding products and services for flow provers: It offers seals and repair parts for all brands of captive displacement provers. In addition to providing state-certified water draws and service for captive displacement Provers, FlowMD is offering replacement seal kits and other repair parts for FlowMD, Honeywell Calibron and Daniel captive displacement provers. Alex Ignatian, Flow Management Devices Managing Partner, completed a demonstration tour through eastern U.S. and Canada consisting of a fully operational trailer-mounted FlowMD FMD-015 prover capable of proving a Coriolis meter and or PD meter. Potential customers had the opportunity to witness all the technologically superior features of the FlowMD prover, including the quiet operation and the volume verification system. A western tour in under way. 602-233-9885, www.flowmd.com.

American Public Gas Association

American Public Gas Association (APGA) Security and Integrity Foundation (SIF) released its simple, handy, risk-based integrity management plan (SHRIMP) for utilities to use to create written distribution integrity management programs (DIMP) plans required by new federal pipeline safety regulations. APGA said all utilities must have written plans no later than Aug. 2, 2011. SHRIMP is an online program that uses a question-and-answer process to collect information about the design, construction, operation and maintenance history of distribution systems. Based on the answers provided by the user, SHRIMP assesses and ranks eight different threats to distribution integrity and records that information into the written plan that is created specifically for each user’s system. Threats are ranked using a risk ranking index model developed specifically for SHRIMP. SHRIMP offers menus of possible additional actions to reduce risks to the system as well as performance measures to monitor the effectiveness of the plans at reducing those risks. Also, where operators have existing programs addressing any threat, SHRIMP allows the user to incorporate these programs into the DIMP plan. The end result is a complete written plan that addresses all the requirements of the regulation. 202-370-6211, www.apgasif.org.

Sullair Corporation

Sullair says at center stage in the company’s booth at the 2010 Global Petroleum Show in Calgary was its 1525XH cfm crash-framed compressor. This 25,000-pound offering will be significant in applications involving pipeline dewatering and testing, onshore controlled pressure drilling, offshore drilling and as primary feed air provider to nitrogen processing units. The compressor is powered by a 6-cylinder Caterpillar C-18 Twin-Turbo diesel engine that delivers 700 hp and employs low emission engine technology to comply with Tier 3 and Stage 3 emission legislation. It utilizes Sullair’s heavy-duty, two-stage air end, which incorporates time-proven spiral-valve technology to achieve maximum performance. Sullair shared its space with Dahlson Industries Ltd., a Calgary-based firm (http://dahlsonindustries.com/) that designed and fabricated the crash frame on the compressor and then delivered it to the show. Kyle Smith, 219-861-5227, www.sullair.com.

Huntingdon Fusion Techniques

Huntingdon Fusion Techniques reports its Argweld® Quick Purge™ systems have been improved significantly. A new argon purging valve arrangement has been incorporated which is optimized for all different pipe diameters. The old adjustment system has been eliminated, so trial setting is no longer necessary thus saving more time on each weld. To help welders identify the location of the purge systems below the weld joint, where it is normally dark, a high-visibility “Glo Strip” has been incorporated centrally between the dams. The firm says this ensures accuracy of positioning. Huntingdon says major international pipework fabricators, including Bechtel Corp. and Chicago Bridge & Iron, have applauded the cost and time benefits accruing from the use of Quick Purge. http://www.huntingdonfusion.com.

Comments