December 2013, Vol. 240 No. 12

Features

PECO Ramping Up Replacement Of Distribution, Service Lines

With about 1,700 miles of its12,000 miles of natural gas distribution and service lines made of cast iron, wrought iron, ductile iron and bare steel, PECO has undertaken an aggressive $34 million a year replacement program.

“Our gas distribution system continues to perform well,” said Ron Bradley, PECO vice president of gas operations. “As part of our efforts to ensure continued reliable service, we have accelerated our work.”

The company, which serves close to 500,000 gas customers in southeastern Pennsylvania, about 90% of whom are residential, expects to increase main replacement from 14 miles to 30 miles per year and bare steel service replacement from 1,800 to 4,000 services per year.

PECO’s long-term infrastructure improvement plan was approved by the state’s PUC in May with the10-year initiative boosting the company’s projected capital investment in the modernization effort by $20 million a year.

With the effort, the company expects to replace all of its aging mains within 34 years and all bare steel service lines within 10 years, accelerating the work by about 50 years. In 2013, PECO replaced 32 miles of existing natural gas main, which is roughly double the amount it replaced annually in previous years. The company has also replaced 3,100 service lines so far.

With densely populated communities among its service areas, PECO is acutely aware of the need to limit the construction’s impact on local traffic and businesses. To that end, the company often finds itself scheduling work around significant local events.

“We don’t want to interrupt parades or soap box derbies,” said Bradley, a 29-year veteran of the natural gas, electric and generation industry. “You want to be invisible as a utility as best you can.”

PECO, according to Bradley, took a “big picture look” at its service areas as well, in order to coordinate efforts with other utilities’ planning work, thereby limiting the overall inconvenience to “one excavation, one repair” as often as possible. Additionally, construction crews will use directional drilling for main replacement and core drilling for service replacement when feasible, and other equipment to limit excavations and avoid digging up sidewalks.

“We discuss our project plans with local townships and municipalities and even our customers as appropriate to ensure we are minimizing our impact as much as possible on the local community,” Bradley said.

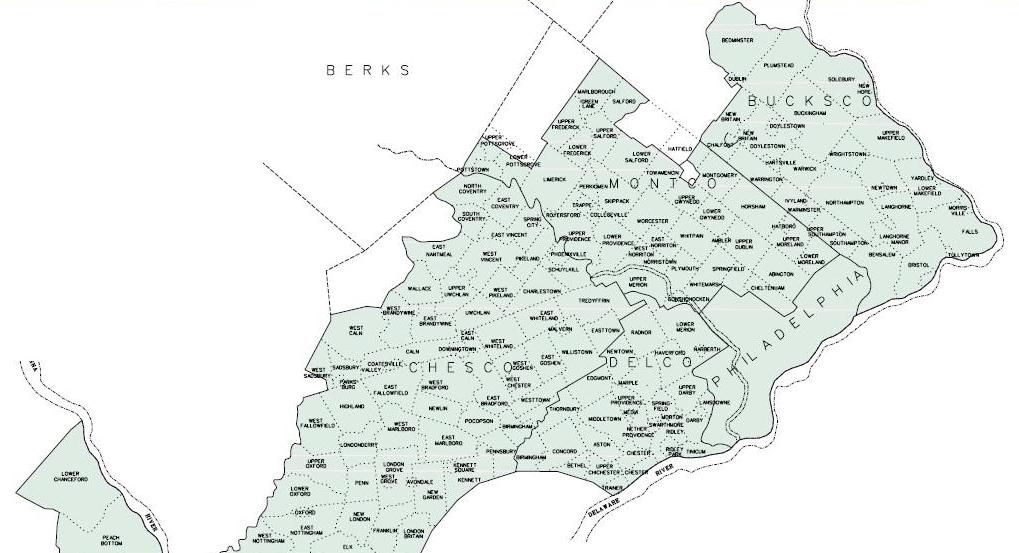

While PECO, which delivered 76.5 Bcf of natural gas in 2012, provides service in the counties surrounding Philadelphia – Bucks, Chester, Delaware, Montgomery and a small portion of Lancaster – it does not serve Philadelphia County. However, the company does deliver electric service to the surrounding counties and Philadelphia County.

PECO will work closely with its sister utility, BGE, in Baltimore, as well as other utilities, to identify a best practices approach to the large effort being undertaken. The company plans to work with several different local contractors during the effort.

The company has not yet filed for reimbursement for modernization investment through the state PUC, but PECO believes its program will be less costly to its customers than the repair costs they would eventually incur from an outdated system.

In June 2011, Bradley participated in a PUC roundtable discussion about strategies and options for gas infrastructure. It was at this time he outlined the company’s planned approach toward modernizing its system.

Bradley, an engineer with a bachelor’s degree from Widener University in Chester, PA and a master’s degree in management from Penn State, began working for PECO in 1984 and has held various leadership positions at the company. Those include gas corrosion manager and generating station manager. He described this eclectic combination of work experience at the combo utility by saying “you tend to tap dance across various jobs.”

Experience at one of his former positions, vice president of Support Services, has proved invaluable to Bradley concerning PECO’s top priority – safety. It was in this capacity that he was responsible for the well-being of the employees and the communities they serve.

“I’ve always focused on the safe performance of our employees and the safety of our customers. To that end, PECO has an exceptional safety program from an organizational standpoint,” Bradley said. “Safety is a focus that permeates through the entire company. It’s a key emphasis for every employee, every day.”

PECO’s commitment to a “safety first” approach was lauded by the American Gas Association (AGA) at the organization’s operations conference in May when the company was awarded the prestigious Safety Achievement Award for experiencing the lowest DART (days away, restricted and transferred) incident rate among large electric and natural gas utilities in 2012.

“America’s natural gas delivery system is the safest, most reliable energy delivery system in the nation,” AGA President & CEO Dave McCurdy, said of PECO at the Orlando gathering. “This is due to the hard work and dedication of the employees of our local natural gas utilities.”

PECO’s Gas Division recorded only two employee injury incidents requiring OSHA reporting in 2012 and one incident resulting in days away from work or restricted work activity. PECO employs about 300 employees in its gas delivery and gas plant operations.

Further Expansion

In addition to the need to replace aging infrastructure, PECO is expanding to provide natural gas to underserved areas through three growth initiatives:

• PECO Smart Natural Gas Conversion, which focuses on helping residential customers convert to natural gas from another energy source. These customers are within close proximity of an existing natural gas main, simplifying the conversion process.

• Commercial conversions, designed to convert large commercial customers to natural gas from another energy source.

• CNG vehicles initiative to convert cars and trucks to natural gas.

PECO already has a number of workers among its 2,100 total employees who are cross-trained for both its gas and electric (which serves 1.6 million customers) segments. This allows the company to dispatch its energy technicians to whichever segment has the highest workload.

“We are constantly assessing our gas system and its capacity for customers,” said Bradley. “More and more customers want to connect to the system due to low commodity price. It’s a big deal to get gas to underserved areas.”

The company, which was incorporated in 1902, traces its roots to The Brush Electric Light Company of Philadelphia, formed in 1881, having originated with the work Thomas Edison.

By Michael Reed, Managing Editor

Comments