June 2013, Vol. 240, No. 6

Features

Just What Is Forensic Materials Engineering?

The work of a forensic engineer can be exciting, challenging and rewarding; however, behind the glamorous veneer, it is high pressure, hard work, frequently requiring its practitioner to draw unpopular conclusions.

Thanks to TV shows such as CSI the role of the forensic scientist is well known. These investigators typically focus on understanding the scene of a crime (or accident). The forensic engineers work focuses on understanding the cause and sequence of events of industrial incidents or working to prevent future incidents from occurring. The forensic aspects of engineering are not new, in fact, the equivalent of modern forensic engineers have been investigating issues with engineering structures for as long as structures have been made.

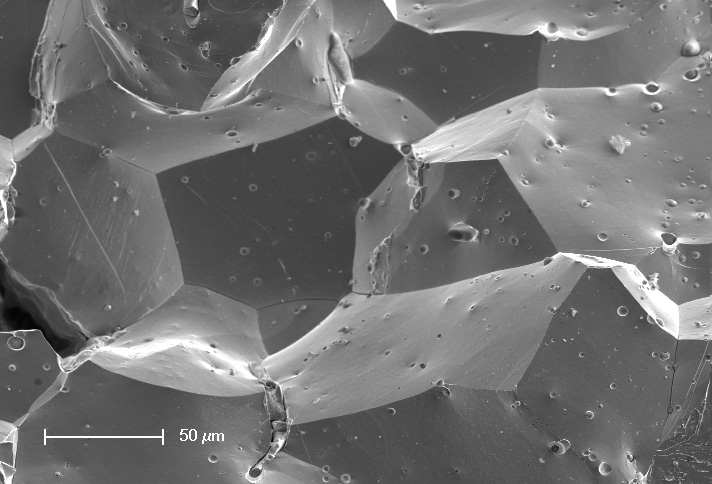

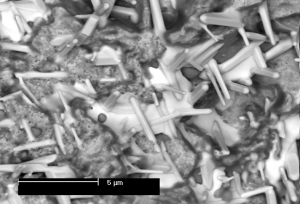

Many of early pioneers of the modern discipline cut their teeth investigating the failures such as the Dee railway bridge (1847) and the structure involved in the Tay Bridge Disaster (1879). These early investigations laid the foundations for the methodology, analytical tools and techniques such as fractography (Figures 1 and 2) and mechanical testing, which modern forensic investigators rely on.

Forensic engineering is considered by many to be the investigation of materials, products, structures or components that fail or do not function as intended – the results being used for legal proceedings. However, the role has expanded from simply providing support to the legal system. Today, forensic engineers are also called upon to add their expertise at other junctures, such as during the design process to help mitigate future issues, in production to help understand how changes may trigger or protect against future issues, and during maintenance to help detect problems before they arise.

Forensic engineers still investigate incidents and issues, but often the motivation is for internal learning, to enhance safety, to increase efficiency and to prevent similar issues from re-occurring, rather than purely to provide evidence to the courts.

People often ask why forensic materials engineers still have a job when we have so much historical knowledge of how materials perform in service. The truth is the world is a complex place filled with unknown variables that can dramatically influence the performance of a given material or system in service. Mother Nature tops the list with numerous examples of foiling the designer’s plan to beat her: icebergs sank the Titanic (the “unsinkable” ship), the Tacoma Bridge (Galloping Gertie) was twisted and undulated by eddying valley winds, and the nuclear power stations of Fukushima were beaten into submission by a tsunami.

All these were designed to beat nature – all failed. A lesser, but nonetheless significant and more common example is pipeline corrosion. It has been known for many years that steel pipelines corrode. We know what the causes are and we have a multitude of effective mitigation methods and corrosion rates that we factor in during the design process. However, anybody who has worked in the oil and gas sector is all too familiar with corrosion-related issues.

Corrosion can range from general corrosion, the only consequence of which is to require increased monitoring to localized corrosion, including pitting and preferential weld corrosion (Figure 3), which can results in catastrophic failures. What, then, is the problem? Did the designers not do their jobs properly? Perhaps the pipeline was not installed or fabricated properly, or materials used were out of specification, or water used for hydro-testing was not up to standard, or sacrificial anodes did not work well enough, cathodic protection system was ineffective, maintenance or inhibition treatments were not carried out properly?

The answer to these questions is “maybe.” It is the forensic materials engineer’s job to identify which of these, or more commonly, which combination of these causes was the problem. If these factors cannot be eliminated, then there are still other factors, including change in product characteristics, accidental effects, sabotage or even acts of God, which also need to be investigated.

What We Do?

The work of a forensic engineer in any discipline is demanding and extremely varied, so if you are happiest knowing exactly what you are going to be doing every day, then perhaps it is not a profession you should consider. If, for example, you hold a staff position as a forensic engineer, it will typically be with a large company, first-tier oil and gas companies being some of the largest employers.

Forensic materials engineers may find themselves working with the design team on a new project one day and carrying out sample collection from a routine maintenance shutdown the next. They could be giving high-level presentations to government officials in the morning, then grinding and polishing a pipe surface in the afternoon. Then, they may have to drop everything and take a helicopter to the site of an offshore incident.

The work of a consulting forensic engineer is equally diverse. Although consultants generally work on more issue-based projects than preventative projects, they can, at a moment’s notice, be sent anywhere in the world in response to an incident. The pace of work depends on the sector and the scale of the facilities being supported. It can be relaxed, with enough time to update one’s skill set. However, these times are commonly interspersed, at short notice, with periods of intense activity and extremely high-pressure projects.

If I had to generalize, I would say the work can be largely divided into the following broad categories:

• Providing expertise at the design stage to help mitigate the risk of issues occurring. Here experienced forensic materials engineers are at their most effective as they help prevent future incidents from occurring.

• Offering advice to production teams on how changes in the nature of the product, maintenance practices or other aspects that may affect the health of the system.

• Providing technical assistance and advice during maintenance and inspection periods to help identify unknown deposits or debris and understand the condition of the facility, which can act as an early warning system.

• Posting incident investigation of fires, explosions, mechanical failures, leaks, production loss, environmental contamination or the release of unknown substances.

• Investigating the failure of specific components – either onsite extraction and a full investigation, or just the laboratory-based activities. This type of project could involve fractography, positive materials identification, mechanical testing, debris or deposit analysis and a wide range of analytical techniques, possibly examining samples down to the atomic level.

• Providing metallurgical, mechanical, chemical or physical testing of new designs or the materials selected in simulated environments, and testing of novel processes before they are rolled out.

• Supplying process or project performance reviews, including scope, schedule, costs and design-deviation analysis, schedule-delay analysis, and review of construction and commissioning protocols or practices. All of these early stage evaluations can have a major effect on the performance of a system in service; therefore, the forensic materials engineer’s views are highly valuable to mitigate the risk of future incidents.

• Providing expert witness accounts of projects they have worked on or forensic analysis of other people’s works in litigation, warrantee claims, arbitrations, mediations or other court proceedings.

Where Do We Work?

The work of a forensic engineer is often sector specific, i.e., a forensic engineer who holds domain-specific knowledge in civil engineering will focus on issues associated with buildings, bridges or roads, etc. Those with subject-specific knowledge in, for example, materials, or more specifically corrosion, have the flexibility to work in a wider arena although a degree of sector-specific knowledge is also required. The oil and gas sector, marine, defense and aerospace are perhaps the largest employers of forensic engineers with materials and corrosion expertise. In this sector the forensic engineer is given the greatest opportunity to work on preventative and issue-related projects. Common sectors in which you may find forensic engineers include:

• Oil and gas

• Aerospace

• Defense

• Construction

• Insurance

• Nuclear

What Makes A Forensic Materials Engineer?

Forensic scientists, who commonly study a forensic science-focused degree at a university, are much less common than academic forensic engineering programmers. The main reason is that forensic engineers generally require a large body of experience to be effective. It is not common to gain a post as a forensic engineer directly upon graduation. It is much more common for a forensic engineer to have a higher degree, a string of professional qualifications, such as PE, CEng, NACE corrosion specialist, three or more jobs behind them and more than 20 years of experience before formally starting their career as a forensic engineer.

Forensic engineers need to have high-level subject expertise and a broad appreciation of the sector in which they practice. This is why the profession is something we have to aspire to and work toward, rather than something to take on early in our careers.

Just as important as academic qualifications and professional experience, the forensic materials engineer needs to possess a wide range of personal attributes to deal with the rigors of the work. Among the most important: high ethical standards, uncompromising objectivity, analytical and methodical personality, excellent communications skills, ability to translate complex ideas to a lay audience, flexibility to handle a wide range of projects, stamina to work to the requirements of a project, focus required to work on a wide range of project types and the resilience and strength of character needed to handle to criticisms and questioning.

Forensic Materials Investigation

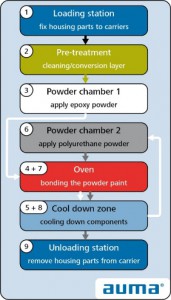

Vital to all branches of forensics is the importance of the investigative methods used and how evidence is collected, handled, analyzed and stored. At the most basic level, a forensic materials engineer will follow a procedure similar to the MTIS© forensic investigation procedure summarized in Figure 4. Each stage of the process relies heavily on established procedures, practices and methods. At every stage the methodology must be visible and understandable with all stakeholders able to trace the methods used to well-established practices such as those defined in recognized standards, including those produced by ASTM, BSI and API. This not only gives customers confidence in your findings, but protects your position should your findings be presented in a legal case.

Most experienced forensic engineers will engage in the investigation stage by first digesting the information in front of them. They will look, observe, identify, photograph, label, smell, touch and, otherwise, soak in what information is available before deciding a plan of attack. They will normally have a healthy fear of the next step, knowing that information could easily be lost if they move too quickly – a fear generated by years of making their own mistakes and getting reprimanded by more experienced investigators.

The process of collecting samples is what commonly triggers comments such as, “That’s what they did last night on CSI.” Although our tools are not quite as showy, and I don’t often wear Armani suits to collect samples from pipelines, we follow similar approaches. After the inspection stage in which everything is labeled and photographed, samples are collected. This can require the use of small brushes and a sample bag, tweezers and other types of probes. At this stage, more sophisticated tools can also be required, such as ultrasonic, boroscopy and radiography. Although it may surprise some, more often basic items, such as a hand lens, color charts or magnet can yield equally valuable information.

Characterization Of Evidence

Forensic corrosion engineers need expertise in a wide range of process-monitoring techniques such as corrosion coupons and sand probes. It is essential they are well-versed in the wide range of onsite, non-destructive techniques which can provide valuable insights. It is also essential that forensic materials engineers are equally at home in the analytical laboratory as in the field. They need a strong toolbox of characterization and testing techniques and the expertise to use them appropriately. A common mistake in the analytical lab is to put a sample in an expensive piece of equipment, press the needed buttons and accept what the machine returns at face value. The forensic materials engineer will not believe the data alone but will search for corroborating evidence and question the data before formulating a hypothesis.

A range of the most common characterizations methods include:

• Digital photography and image analysis

• Scanning electron microscope

• Energy dispersive X-ray analysis

• X-ray fluorescence

• X-ray diffraction

• Electron backscatter diffraction

• Mechanical testing capability

• Replication techniques (Figure 5)

• Optical microscopy and metallography

• Fractography (Figure 6) and failure investigation techniques

It is the appropriate application of these tools, which turns abstract samples into useful pieces of evidence, that can help the team piece together a given scenario and understand all the factors leading to the incident.

Analysis Of Findings

Collection of data and characterization of samples is important, and it must be done in a suitably rigorous manner. Apart from domain expertise and sector-specific experience, the forensic engineer should be well-versed in a wide range of techniques useful in understanding data in the context of the specific project. Tools such as fault tree analysis and failure mode effect analysis, can be used to understand data while statistical tools can be applied to understand the significance or importance of a given piece of data or hypothesis.

Many of these tools can be too linear and inflexible. When using them as a working mechanism, one must always keep active motors running in the background, driven on flexibility of thought. Questions, assumptions and postulations need to be answered and verified. Common sense is also vital. The second fundamental principle of forensic methods is “forensic materials engineers do not believe anything” – not the views of an individual, not a piece of data, not the opinion of an expert. All information must be collected, analyzed and validated against all available sources, including other pieces of information, the engineer’s background experience, available literature and views of other experts. Only then do we consider it to be evidence.

A senior member of a large organization once said in an important meeting to discuss the results of a failure investigation: “Don’t let the facts cloud intuitive judgment.” Most of those at the meeting sighed. He may not have been far from the correct approach. With experience comes knowledge that data can be easily misinterpreted. The data should point the way, but – if after 20 years of seeing similar occurrences – the facts are telling one story and your intuition is telling another, something may be wrong. You may be asking the wrong questions. If so, everything needs to be rechecked, revalidated and new questions formulated.

Forensic engineers have a range of prescribed methodologies to help analyze data. As an illustration, cracks were found in an offshore heat exchanger. The approach in Table 1 was devised to help interpret the findings:

This table was produced by using a technique put forward by Kaori Ishikawa and is usually called a fishbone diagram. Keeping it as a table, however, allows it to evolve and be dynamic throughout the investigation. Flexibility is in-built and allows addition or removal of information. As it grows, connections can be made between cells and lead to well-thought-out conclusions. Spider diagrams, or top-level mapping in process excellence terms, can also be used to great effect, building the diagram with arms and legs generated by questions and postulations awaiting verification. At all stages of developing these diagrams, you can still use defined analyses methods to help conclude a specific area of the investigation.

The conclusion of this investigation was that design, material and operating practices were all to blame – a multi-variable problem. A redesign was scheduled to improve geometry to reduce stress concentrations generated by poor operation on a material with a microstructure, consisting of low-fracture toughness elements.

Closing Comments

Forensic engineering is an exciting and rewarding profession; however, it requires broad-based experience and in-depth, domain-specific knowledge. The domains we work in, such as forensic materials engineering or forensic corrosion engineering, are challenging. The work provides a valuable service by increasing understanding and helping prevent future environmental disasters and loss of life.

Authors

Andrew Spowage holds a doctorate in engineering and heads the Mechanical Materials and Manufacturing Engineering Department of the University of Nottingham, Malaysia campus.

Eur.Ing. Nigel Brewitt (MMet, CEng, FIMMM, MIMM) Director. MTIS Sdn. Bhd, Nigel@mtis-malaysia.com

Comments