September 2015, Vol. 242, No. 9

Features

Orifice, Ultrasonic Meters in Wet Gas Flow Service

Natural gas producers regularly have to meter wet gas flow. Separator systems or multiphase wet gas meters are beneficial but the economic reality of many applications is that standard gas meters must be used. Hence, understanding the wet gas performance of gas meters is important.

Wet gas flow is a very adverse flow condition. However, operators want the problem solved and manufacturers want to persuade operators that their meter copes with wet gas. A can do attitude pervades. But in truth wet gas flow seriously degrades all gas meter design performance specifications. In this article we look at the known wet gas performance of orifice and ultrasonic meters.

Orifice Meters, Wet Gas Flow

Years of testing show the orifice meter to have a very reproducible and predictable wet gas flow performance. Concerns that the orifice plate may “dam” liquid or cause an unsteady DP signal have proven unfounded.

CEESI videos of wet gas flow through orifice meters show that an orifice plate does not dam liquid. Figure 1 shows a still from video of stratified flow of natural gas and light liquid hydrocarbon flowing left to right through an 8-inch, 0.6 beta orifice plate. No damming was evident during the 30-minute tests.

Without the plate present, a stratified wet gas flow has a liquid depth. With the plate present, this liquid depth showed no significant change over time. Furthermore, it was evident that rather than damming, the stratified liquid rose up through the orifice (Figure 1). This stratified liquid can leave a “tide mark” on the upstream face of a plate, but this is only an indication that stratified flow (of a given liquid depth) approached the plate; it does not mean the plate dammed the liquid.

The CEESI videos showed liquid entrained downstream in the recirculation area. Whereas there has been concern that this could cause DP instability, this has been shown to not be a significant problem. Wet gas increases the DP signal (causing the over-reading) and also increases the DP standard deviation (i.e. fluctuation around the average).

However, although wet gas flow DP has a significantly higher standard deviation than the dry gas flow DPs, massed orifice meter wet gas data sets have shown that the average DP is still repeatable and reproducible. Stability of the DP and liquid damming is not a problem for orifice meters in wet gas flow service.

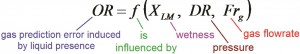

ISO TR 11583 [1] and ISO TR 12748 [2] show an orifice meter wet gas flow correction factor. This correction factor effectively says:

This ISO gas meter wet gas correction factor is the most comprehensive yet produced. The Achilles heel, as with all gas meter wet gas correction factors, is the requirement for the liquid flow rate to be found from an external source.

This is a real practical problem, but it is the reality of using any gas meter for wet gas service. There are ways of estimating the liquid flow rate, e.g. tracer dilution and test-separator histories, but these methods are only truly valid at the time of the measurement. Liquid flow can change between checks and therefore gas meter liquid loading monitoring systems are desirable.

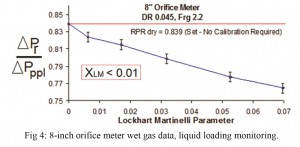

Prognosis (Lewis [3]) is a simple and effective proprietary orifice meter diagnostic/liquid-loading monitoring system. Figure 3 shows the Prognosis setup. Two additional DPs are read, the recovered and permanent pressure loss (PPL). Figure 4 shows sample wet gas data from an 8” orifice meter at CEESI. The recovered to PPL DP ratio is sensitive to wet gas. A reduction in this ratio, combined with increasing DP standard deviations, signifies increasing wet gas liquid loading. This technique can identify wet gas at XLM ? 0.01.

Ultrasonic Meters, Wet Gas Flow

There are multiple ultrasonic meter (USM) designs. There is sporadically published wet gas research on USMs, although this research is type-dependent. However, the limited published information shows common wet gas traits between different designs. It is therefore generally valid to discuss one USM and treat the results as generally valid for USMs as a group. There is as yet no published USM wet gas correction factor.

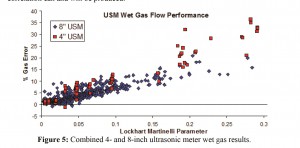

It is sometimes claimed that USMs work well with wet gas flow. This statement means the meter continues to read a signal. However, this signal is adversely affected by wet gas flow. USMs, like all gas meters, cannot correctly measure the gas flow of a wet gas flow. Figure 5 shows CEESI wet gas data recorded from modern 4- and 8-inch Westinghouse USMs. The USMs have an over-reading that is related to the Lockhart Martinelli parameter (i.e. the wetness).

There is a significant amount of scatter. Unlike the orifice meter, this is unrepeatable scatter and not the predictable effects of pressure and gas flow rate. Such results explain in part why no USM wet gas correlation has yet been produced. A wet gas correlation is a statement that industry truly understands a meter’s wet gas performance to the point that correct performance predictions can be made. If and when a USM is shown to have reproducible wet gas performance, a wet gas correlation can and will be produced.

USMs have a well-established general diagnostic system. Manufacturers have suggested that path performance, path speed of sound (SOS), path turbulence, symmetry and profile factor are the best diagnostics to “see” wet gas flow. Figures 6 through 9 show these diagnostics sensitivity to wet gas flow. These 8-inch USM diagnostic results are from the same wet gas flow conditions as the 8-inch orifice meter diagnostics shown in Figure 6.

The performance diagnostics indicates a problem when path 4’s performance drops noticeably at XLM > 0.015. The SOS diagnostics indicates a problem when path 4’s performance drops noticeably at XLM > 0.02, just below the path fails. The turbulence of all paths has no clear relationship with wet gas until path 4 fails at XLM > 0.03. The most obvious (and best) indication of wet gas comes from a symmetry vs. Profile Factor plot. This shows an abnormal flow condition by about XLM > 0.01. Hence, the USM diagnostic suite indicates something is wrong by a wetness of XLM > 0.01.

The USM diagnostic suite will indicate something is wrong by XLM > 0.01, but it is a generic alarm, not wet gas specific. Nevertheless, the USM diagnostics do alert the operator to a problem, and could potentially help monitor wetness. The USM diagnostic suite begins to show a distinct pattern that can indicate wet gas as the specific problem as Path 3’s performance begins to drop at XLM > 0.03.

Conclusions

Wet gas flow has adverse effects on all gas meters. Both orifice meters and USM have degraded performance in wet gas applications.

Wet gas causes the orifice meter to significantly over-read the gas flow. However, this over-reading is predictable and for a known liquid flow rate an ISO-published correction factor can correct the gas flow rate prediction to 2% at 95% confidence. Furthermore, an orifice meter liquid monitoring system is available that can specifically identify wet gas flow by XLM ? 0.01.

Wet gas causes the ultrasonic meter to significantly over-read the gas flow. To date, no ultrasonic meter correction factor has been published. However, the USM diagnostic system is capable of identifying a generic problem exists by a wetness of XLM ? 0.01.

References

1. ISO TC30 TR 11583, “Measurement of Wet Gas Flow by Means of Pressure Differential Devices Inserted in Circular Cross-Sectional Conduits.”

2. ISO TC193 TR 12748, “Natural Gas – Wet Gas Flow Measurement in Natural Gas Operations.”

3. Lewis K., “The Response of Differential Pressure Meters and their Diagnostic System to Wet Natural Gas Flow,” Canadian School of Hydrocarbon Measurement, Calgary, March 2014.

Figure 2: Massed 2- to 4-inch orifice meter wet gas data with & without the ISO correlaton.

Comments