July 2024, Vol. 251, No. 7

Features

Bridging the Skills Gap: A Comprehensive Guide for Measurement Technicians

By Brad Massey, Technical Systems Specialist, Mustang Sampling

As retirement brought on by the Great Crew Change cycles out a large portion of experts, companies are faced with hiring a new generation of workers. Within the industry, most employees are over 55 or under 35 years of age, creating a significant skills gap within the workforce. The measurement sector is not immune to these knowledge gaps.

The problem is that many measurement technicians learn their skills on the job through troubleshooting and hands-on experience, making it difficult to fill the skills gap without proper mentorship and training. Additionally, due to cultural shifts in the last decade, it has become more difficult to attract and retain skilled measurement technicians.

To combat this issue, companies are targeting outside industries and more diverse workers with competitive compensation and flexible schedules.

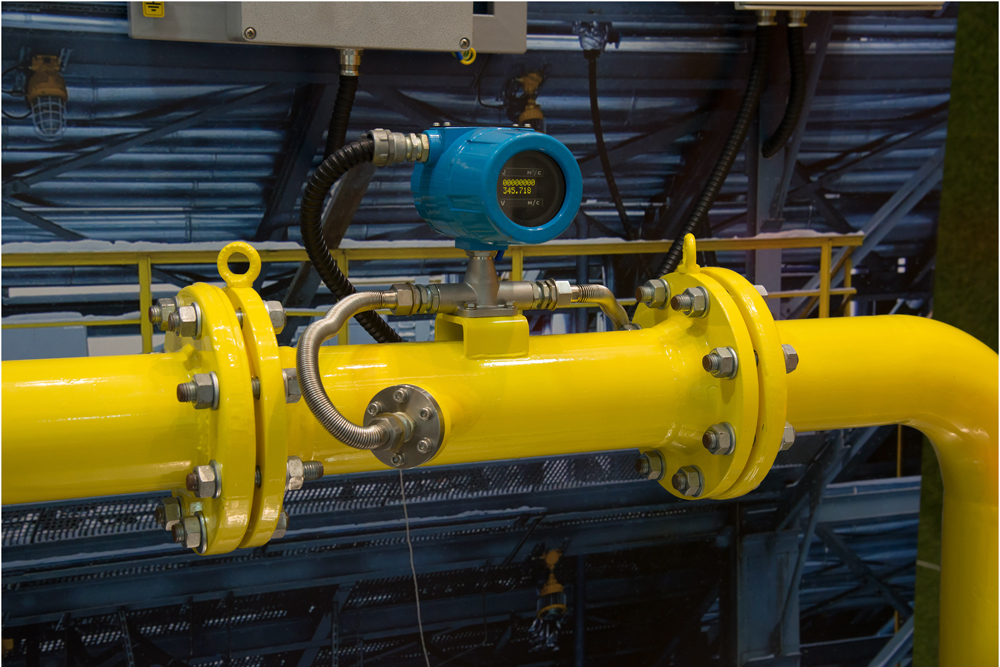

In preparation for the influx of new talent, it’s important to be transparent about what a measurement technician's role entails. A measurement technician is vital to pipeline operations, as they are responsible for the maintenance and operation of gas metering and regulation stations.

Because of this responsibility, they are faced with several requirements to be able to complete their tasks effectively. They are responsible for testing and calibrating meters, gas sampling, analysis and troubleshooting. All of this is done to support commercial transactions and prevent lost and unaccounted for (LAUF) gas.

Understand Fundamentals

Understanding the fundamentals of measurement is an overlooked area of a measurement technician’s job. When new technicians start, it’s possible that companies prioritize getting them in the field and working, instead of spending time teaching the basics.

Measurement can be a complex subject, and not properly understanding how it works can lead to mismeasurement. By taking the time to learn this information, the measurement technician can be set up for success in their career.

Adapt to Changes

Throughout a measurement technician’s career, the industry will grow and transition. Technology advancements are prime examples. Those retiring today started with mechanical chart recorders, which have transitioned to flow computers tied to SCADA and gas accounting systems.

Even measurement devices have transitioned from positive displacement (PD) and orifice meters to ultrasonic and Coriolis meters. Technology is only predicted to evolve further, as A.I. becomes more integrated within the industry through the development of smart meter technology.

To be successful, it’s important that a measurement technician becomes proficient at operating and maintaining equipment. This includes not only knowing the equipment itself but also staying updated on industry standards. New technicians are expected to have baseline computer knowledge to execute their tasks.

Navigate Repetitive Tasks

A technician’s job can become quite repetitive, as measurement equipment is tested on a scheduled basis. However, measurement is based on transactions requiring documentation, so work must always be conducted accurately to prevent financial losses. Therefore, a technician should remain attentive to avoid errors.

Preventative Maintenance

For those interested in efficiency, there is a growing aspiration to transition from scheduled maintenance to predictive and prescriptive methods eventually. This shift emphasizes the need for more focused and purposeful work. These procedural changes will encourage technicians to investigate data clues to find potential problems.

For a new technician just starting out, it’s difficult for them to know how to preemptively troubleshoot issues. To get to this point in their career, technicians should take time to learn from mistakes: learn what went wrong, why things are not working and how to improve next time. As this happens, the technician will learn how to do things better and further understand how to prevent mistakes from happening.

Communication Skills

Communication with others is at the core of a measurement technician's job. Since measurement centers around financial transactions and is judged by LAUF metrics, technicians must be able to communicate problems and suggest solutions when problems are small. Communication typically happens between customers, operational personnel and gas controllers.

Developing and learning proper communication may be time-consuming, but it will ultimately result in more accuracy.

Learning Opportunities

A measurement technician’s development does not stop after landing the job. As most of the knowledge required for the job isn’t intuitive, it’s important that technicians seek continuous learning opportunities.

There are several measurement-specific short courses offered in person by institutes, such as the International School of Hydrocarbon Measurement, Appalachian Gas Measurement Short Course, American School of Gas Measurement & Technology and Western Gas Measurement Short Course.

Companies can also develop in-house training programs, utilizing internal resources or industry-supported training. This training can be tailored to company-specific processes. Blended structure programs typically perform the best, as they allow the student to apply concepts learned in the classroom.

Organizations like the Gas Training Association provide curriculums created by measurement subject matter experts (SMEs) that companies can adjust to fit their needs.

Vendors provide resources such as “lunch and learns” and equipment manuals. Other available resources include publications from associations like the American Gas Association, American Petroleum Institute, Pipeline Research Council International and the Southern Gas Association.

Advice For New Technicians …

Regardless of your starting level as a measurement technician, here are a few tips that can help you be successful in your career.

- Find Your Inspiration: Find a role that inspires you every day and develop a long-term plan for how to get there. Then, find a way to make progress (either big or small) to reach that goal. Don’t stress over having it all figured out in one day.

- Learn from Experience: Listen to experienced workers while you have the chance, but don’t hesitate to validate the lessons you have learned to make sure they fit with your company.

- Stay Proactive: Don’t become idle. Keep finding ways to grow and learn within your job. When faced with free time on the job, ask for resources that provide information and training.

A measurement technician’s role can be demanding, as it requires a blend of hands-on skills, technological proficiency, and effective communication. As the industry continues to navigate the Great Crew Change, the challenge of fulfilling skill gaps can become more pronounced.

By positioning new measurement technicians for success from the start of their careers, it will be easier to meet that challenge.

Comments