February 2019, Vol. 246, No. 2

Features

Pipeline Management Office Proves Beneficial to Pipeline Digs

By Richie Ngo, Supervisor of Project and Program Management, Gas Transmission Systems (GTS)

The Digs Project Management Office (PMO) is often referred to as the “Big PMO” because of its sheer volume of work and its potential effect to the pipeline assets and its stakeholders.

Take maximum allowable working pressure (MAOP) validation as an example. Performing direct assessments to verify a pipeline’s MAOP is not new, but as federal regulations become more stringent, the volume of digs will increase significantly, and operators need to keep up with the pace.

Over the past six years, I’ve worked on over 1,000 digs – small excavations, for the sole purpose of performing direct assessments and material validation. Due to the small scope of an individual dig project, it is fast-paced, usually lasting one to three weeks in construction.

Why Dig?

Per ASME B31.8S, direct assessments are performed to investigate and mitigate time dependent, and time independent threats, along with human error. Examples include external corrosion, internal corrosion, and stress corrosion cracking direct assessments, in-line inspection direct examinations, casing mitigation, material verification, MAOP validation and weld verification.

A dig starts off as purely investigative but may result in a repair method as simple as recoating the pipeline, or as invasive as requiring an outage to replace the affected pipeline section. Therefore, digs need to be planned carefully to minimize effects to the pipeline’s continued safe operation and service continuity.

With the increased demand for direct assessments, a systemic approach is necessary to perform large volumes of digs without losing sight of the detailed analyses required. This is where a PMO can be especially beneficial.

In traditional project management, we work in sequence: initiate, plan, execute, monitor and control, close. When one process is complete, only then can the next one begin. Here requirements are fixed, only cost and time vary.

A PMO, on the other hand, uses a parallel mode that allows companies to manage not by a central line of control, but by groups or functional teams. The scope of Digs is much smaller in comparison to a strength test, ILI or replacement. Accordingly, many digs projects on the same pipeline asset are forced to react to the waves of the bigger projects and can result in massive rescheduling if not planned effectively. The PMO allows us to be proactive and determine when to properly execute the work not just by providing more visibility, but by creating an environment of teamwork and ownership.

Imagine the decisions you can make when you have the breadth of knowledge represented by all subject matter experts in one room. Functional teams have the authority to make on-the-spot decisions and solve issues to avoid wasting time and effort. Being closely involved in the process, the combined functional knowledge within the PMO helps it tackle most of the challenges that generally hinder progress.

Unless there is a need to make extreme decisions, team members rarely need to bring matters to their manager. Thus, decisions are made and implemented quickly. In a typical Digs PMO meeting, we cover over 50 digs in just one hour! We focus only on the critical path items for each dig. If the dig is on track toward meeting its next milestone, we move on to the next dig, period.

Priority Factors

Express lanes at the supermarket are a simple and effective way to alleviate congested lines: less items to buy, the quicker the line moves. When planning to execute a large volume of digs at one time, it can become increasingly challenging to prioritize, but the challenge can be alleviated using something similar to an express lane.

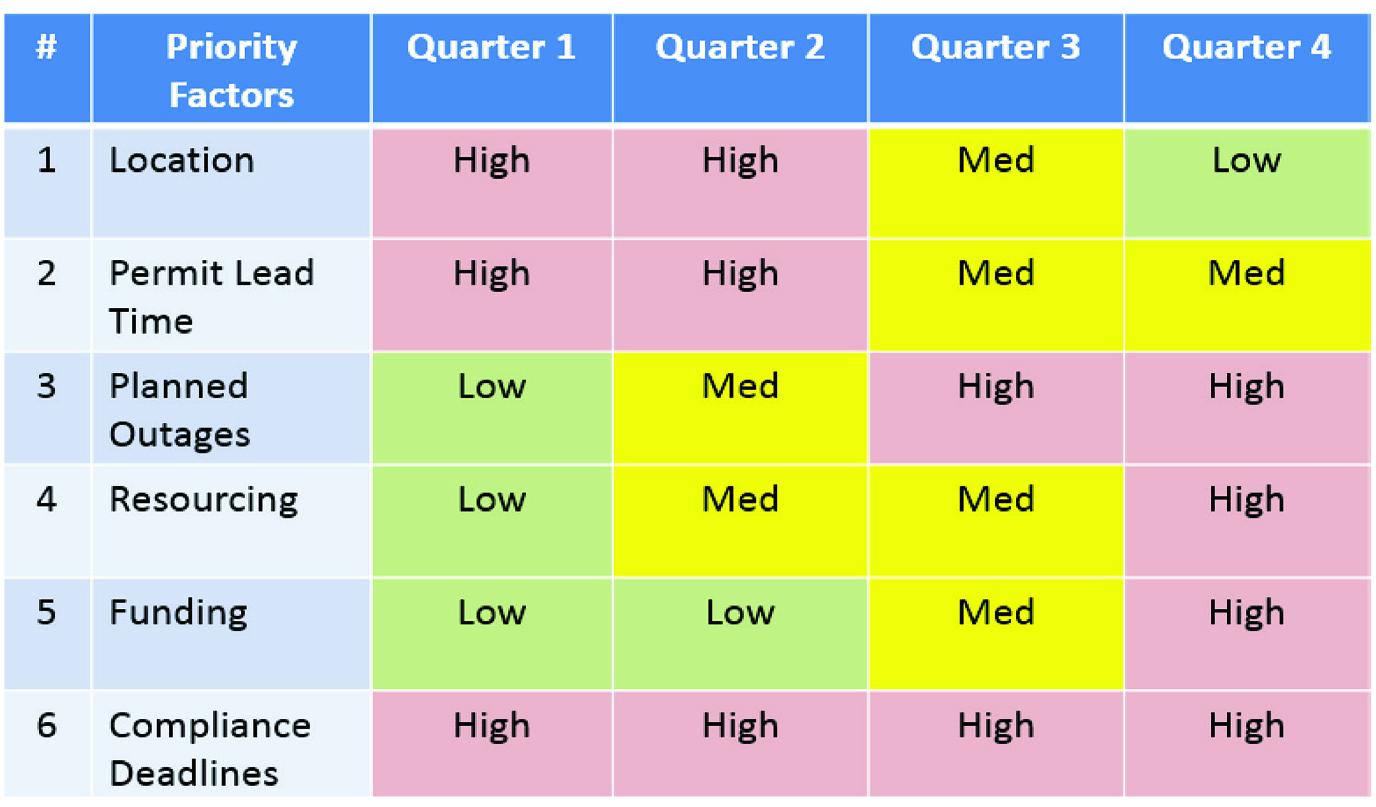

The top six priority factors that impact schedule are: location, permit lead time, planned outages, resourcing, funding and compliance deadlines. The priority of these factors will be based on their impact to other digs within the PMO and projects outside the PMO that affect the same assets and resources.

How these priorities change over time:

- Quarter 1: You’re planning the work before any digs are executed, so try to bundle them geographically. Perhaps it rains a lot this time of year, so let’s work on digs expected to have little to no groundwater first, in locations less susceptible to wet conditions, such as pavement, or are known to have less permeable soils.

- Quarter 2: The weather is clearing, and you’re receiving more digs systemwide. It is now possible to bundle longer lead permits together, so they are ready to execute prior to compliance deadlines.

- Quarter 3: Most of the digs needed to execute this year have been received and a full understanding of their effect is known. The effect of planned outages from other workstreams should be the focus. Plan around them, be attentive toward digs that require outages and plan those strategically. If those digs turn into immediates requiring a temporary pressure reduction, we can incorporate it into the system with minor impact on other outages that have been planned for months.

- Quarter 4: The last stretch of digs that need to be executed is at hand. Look closely at all execution resources such as pipeline engineers, construction, inspection and direct assessment teams. Can the work be allocated so it is normalized throughout the teams at an aggregated level? Don’t overload one construction crew when another crew is available and looking for work.

Depending on the time of year, the factors that drive the work will change in priority.

First, an emphasis is placed on planning work by location and permit lead time. This emphasis changes toward outages, resources and funding approaching at the end of the year. Of course, meeting compliance deadlines is always the highest in priority.

Then there’s the “Code Red! We just got these digs, but we needed them done yesterday!” Although nerve-racking, the same principles apply. These digs can still be executed successfully, because we’ve created a PMO in which we can relay the urgency in timely fashion, follow measurable objectives to meet collective goals and have appropriate leadership backing for our decisions.

Hopefully, you can see the benefits of having a PMO, but it’s not perfect. Here are some challenges from my own personal experiences. Some we resolved one year only to have them recur the next. Others may have been due to a change in leadership or program direction.

Digs PMO ≠ other PMO: Although it is convenient to take existing processes and procedures from other successful PMOs and apply them to the Digs PMO, not all PMOs are created equal.

This goes back to the PMO mandate. Why was it created in the first place? More likely than not, the mandate will not align with other PMOs as it is subject to interpretation by leadership. Take earned value management as an example. Using earned value management can be a great way to measure project performance and progress, but if it takes one to two weeks to compute earned value, you may already be done with the digs project. It’s like completing a project and later creating the project budget.

Generating digs with appropriate lead time: Digs may not be generated with enough time or information prior to the desired deadline to execute the work. This is not sustainable and may infringe on the success of other projects affecting the same assets and resources.

Timely cut-outs generated from digs: Digs are purely investigative, but sometimes, you come across digs that expose serious issues, and a decision is made to cut out and replace that section of pipe. When should you cut it out? How does it impact the system? What about funding and permitting?

Without proper planning on the front end, execution suffers on the back end. Is it worth the time, effort, and money to creating contingency projects ahead of time? Maybe not at the beginning of the year (see table), but contingency plans may be necessary in the third or fourth quarter.

Unnecessary standby resources: The last thing you want is onsite resources waiting for a decision. Having one crew move from one dig to the next minimizes standby costs. To achieve this requires proper construction management so crews can move effectively to the next dig without waiting.

By ensuring this, we can save in upwards of 75% of mobilization and stand-by costs. What if one dig is needed and the next closest dig is 100 miles away? Should we wait until there are more digs close by? What if this dig has an earlier compliance date than the rest?

Conclusion

The Digs PMO has proved to be a valuable tool for pipeline operators because it (a) consolidates all phases of the integrity verification process, (b) increases visibility and communications between affected workstreams, and (c) minimizes redundancies with projects inside and outside the PMO.

A PMO isn’t just about setting up a framework that allows for efficient and effective project management. It’s also about creating a company culture that is transparent from the top-down and bottom-up. By understanding the overall organizational priority and having visibility into each other’s strengths and weaknesses, we’re able to foster an environment of openness, teamwork and collaboration that leads to more successful projects at the end of the day. P&GJ

Author: Richie Ngo joined GTS in 2012 and has extensive experience in process improvement and developing the Digs Project Management Office (PMO).

Comments