June 2020, Vol. 247, No. 6

Tech Notes

Living Live, Leak Free with HDPE Hot-Tap Solution

High-density polyethylene (HDPE) pipe has been touted for its leak-free and long service life properties for decades. When gas and water service companies add new mains and service lines, these piping systems can remain entirely HDPE and leak-free with hot tap tools.

The main benefit to this alternative procedure is the ability to add new service lines to live gas and water lines without any disruption of service. In the past, entire systems would be shut down any time a gas distribution or water utility needed to expand their systems.

For gas companies, stopping the flow meant the release of gas and methane emissions into the atmosphere not to mention the disruption of service to their customers and costs associated with the loss of product.

But with the aid of hot tap tools, water customers can still drink from the tap, take a shower and do the dishes. Gas customers can stay warm and cook on their stoves simultaneously as these new lines are being installed.

Safety of the operators and the environment is of the utmost importance when hot tapping new lines. But with proper training, well-maintained fusion equipment and adherence to the pipe manufacturer’s guidelines, hot tapping is a safe and time-proven solution.

Hot-Tapping Process

McElroy designs hot-tap tools that have been widely used in the field since the 1970s in addition to other fusion tools that make hot tapping a trouble-free process.

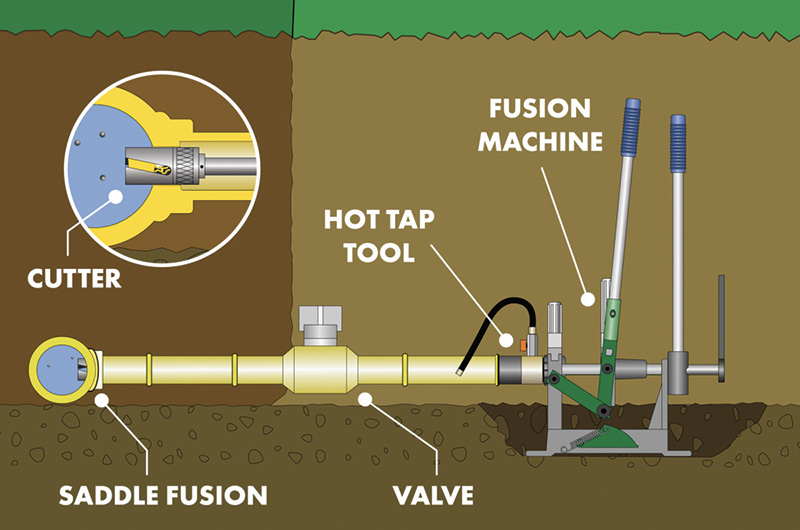

The process starts with a saddle fusion. A branch saddle is fused onto the main pipe using a sidewall fusion machine such as a McElroy Sidewinder, which is designed to fuse branches, tapping tees and service fittings onto mains from 1 ¼- to 4-inch IPS.

Measurements are now taken of the overall length and the pipe and ball valve are fused onto the saddle. Next, the hot tap is fused from the ball valve.

While the valve is open, the cutter of the hot-tap tool is driven through the valve and branch saddle and up to the outer diameter of the main pipe using a small, manual butt-fusion machine, such as a McElroy 2LC or Pit Bull 14 fusion machine. As the cutter is driven through the outside diameter of the pipe, the shavings and plug are completely retained which keeps the main free of debris.

After pulling the cutter back through the valve, the valve is closed. The hot tap tool is then cut from the valve after purging the gas or water from the assembly.

The process is completed after the service line is butt fused to the valve. Now the valve can be opened, and a leak-free, long-life system has been created without ever having interrupted the flow of gas.

Testing Tools

Pressure testing HDPE piping systems is also a quick and easy process. McElroy’s test caps are designed to pressure test one section of pipe at a time without having to wait for a completed system to be installed.

Installation of the test cap is as simple as sliding the pipe ring over the end of the pipe and allowing the o ring seal to seal against the pipe. Once fitting onto the pipe, the system can be pressure tested. Always bleed all pressure from the test line before removing the test cap.

Once the gauge reads zero psi, the test caps can be removed. These testing caps are not designed to be used as a permanent cap. Cut and discard the pipe to a length of at least 1-inch beyond the farthest position that the pipe ring was situated.

The test caps can be used repeatedly but should be inspected before each use. All grease, oil and foreign material should be removed from the grip plates. Test caps should be stored in an area that is free from dirt and residual materials.

Comments