June 2021, Vol. 248, No. 6

Features

Strategic Approach to Automated Leak, Rupture Detection

By Paul Dickerson, Global Products Leader, Emerson, and Phanindra Kanakamedala, Product Manager, Emerson

Remaining vigilant is the best approach when mitigating oil and gas pipeline leaks and ruptures, particularly with new legislation and other requirements that can lead to penalties and fines, not to mention the negative impact on a company’s image. In the past few years, the industry has seen a number of changes in how pipeline leak and rupture detection is being handled.

Governments worldwide are prioritizing the matter, given the impact of pipeline releases, including environmental impacts, emissions targets and the effect on the public. Examples of recent changes include updates to the United States’ Pipeline and Hazardous Materials Safety Administration (PHMSA) regulations and the new Protecting our Infrastructure of Pipelines and Enhancing Safety (PIPES) Act of 2020, both of which are imposing more stringent requirements.

There are many notable incidents of pipeline releases driving regulatory transformation. For example, due to an unrecognized leak, a liquids pipeline operator released over a million barrels of product into an environmentally sensitive area in 2020.

In 2019, a natural gas transmission line ruptured and an ensuing explosion destroyed nearby construction. This release was estimated to be over 90,000 cubic feet. Fortunately, there was no loss of life with either incident, which is often not the case with natural gas pipeline releases.

Accidental hits to pipelines can be catastrophic. Two workers were killed and several more sustained serious injuries when a backhoe struck a pipeline and caused a rupture in 2019. The bottom line is, with any unexpected pipeline release, there are often significant human, environmental and economic impacts.

While leak detection often is considered during pipeline inspections, consideration should be given to the automation of pipeline leak detection. This automation technology accelerates the time window in which a leak is detected, subsequently minimizing the consequences.

Pipeline Variations

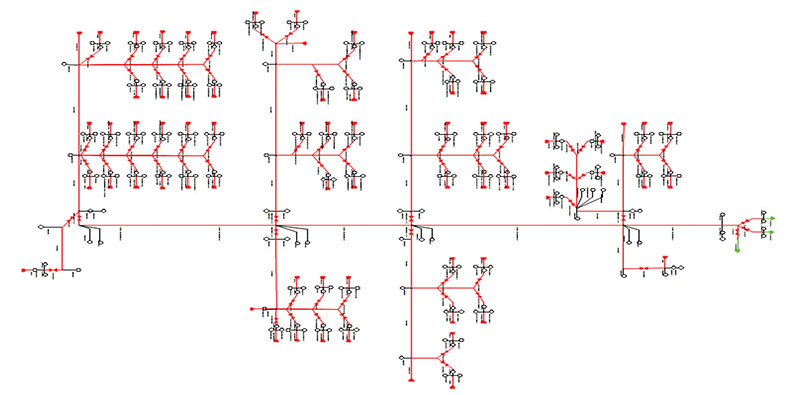

Pipelines, for the purpose of leak detection, can be categorized broadly by geometry, transported product and operational philosophy. For example, gas lines can be operated in either a gaseous phase or a dense phase, while liquid lines can be operated with or without slack conditions. All lines may be subject to elevation changes, or the geometry may generate complex meshed grids.

Operators also should consider factoring in the pipeline location. For example, as suburbs grow, there is encroachment on pipeline rights-of-way, which impacts the risk analysis that must be performed in the selection of an appropriate leak detection strategy.

It is important to factor in the pipeline parameters when selecting the type of automated leak detection solution, including the instrumentation and communications that will be required to ensure the best possible results.

Most pipeline systems will have necessary flow, pressure and temperature measurement installed, as well as a SCADA system or distributed control system (DCS) available for operational pipeline control. An automated pipeline leak detection solution normally can be integrated into these platforms with common data interfaces.

Detection Methods

There are many ways to detect leaks on a pipeline system. External methods tend to be periodic, including flyovers and visual inspections. These types of leak detection methods are ideally suited to identifying small volume leaks that may be released from a very small aperture, as in a failing O-ring on a valve, before they become a much larger issue.

Internal leak detection, in general, is much more automated and offers alarms and alerts much closer to real time. There are several methods of leak detection that can be applied, and the choice of technology can be adjusted to suit the needs of a particular pipeline depending on the system, legislation, operating philosophy, and budget.

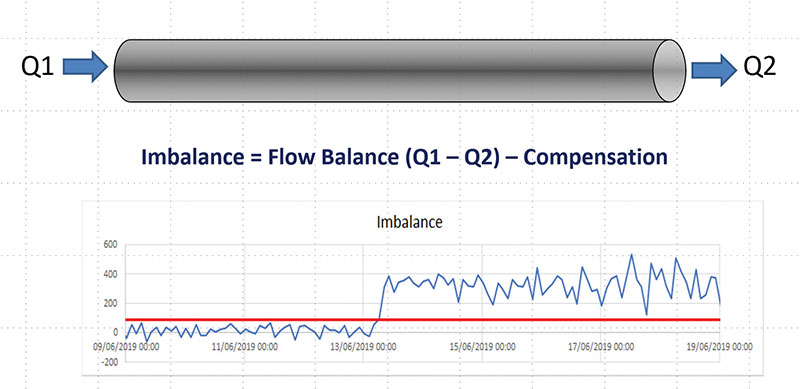

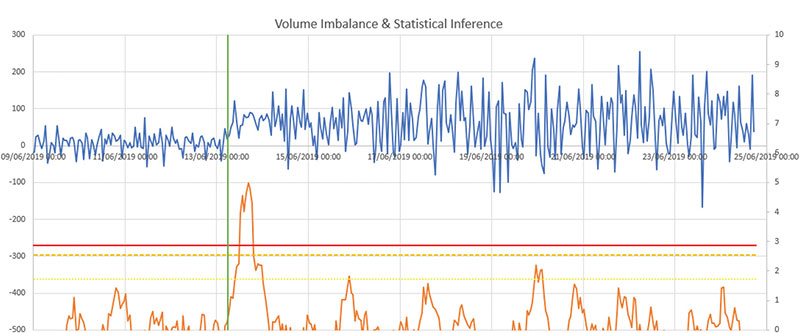

For the most part, internal leak detection methods fall into several categories: mass balance methods (mass balance, compensated mass balance and real time transient model [RTTM] compensated mass balance), statistical methods (statistical, artificial intelligence and machine learning, and pattern recognition), negative pressure wave (NPW) or monitoring methods (pressure/temperature, pressure point analysis, etc.)

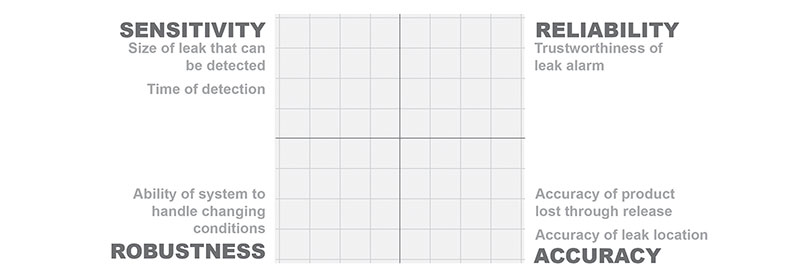

The type of leak detection method selected will vary depending on performance requirements, which often are categorized by the sensitivity of the system. This characterization is based on the system’s effectiveness in several categories: detection (the smallest leak that can be detected within a certain time frame), reliability (trustworthiness of the system), robustness (the ability to continue operating under changing process conditions) and accuracy (the ability to locate a leak once detected as well as automatically measure the volume that has been lost).

When deciding on a leak detection technology, it is helpful to create a matrix of the four primary performance requirements of the optimal system to help clarify and connect the requirements. Taking this step also helps to solidify the budget and implementation framework that will be required.

For example, if a very accurate location is required, the optimal solution will offer RTTM or negative pressure wave methods. If detecting very small leaks is critical, it is best to choose the RTTM or an appropriate statistical method. However, the technology to detect and locate very small leaks with the highest degree of accuracy via an automated leak detection strategy likely can be found within an RTTM-based system.

The installation of a leak detection system also requires a level of maintenance and upkeep. Pipeline physical properties change over time, and those changes need to be properly tuned into the leak detection system.

Systems Innovation

The landscape of automated leak detection is changing. Availability of new technology, such as Emerson’s more advanced pattern recognition, artificial intelligence and machine learning algorithms, which can inject self-learning adaptive methods, is paving the way for greater sensitivity, accuracy, and alarm management and attribution.

External methods also are moving closer to real-time detection of anomalies, including fiber optics, which has excellent instruction detection capabilities, or plume detection solutions for early warning within line of sight.

Additionally, the software needed to automate and alarm as well as attribute the alarm for these systems is migrating to the cloud. There are many benefits to this migration, including enhanced ease-of-use and accessibility of these systems.

A pipeline integrity management program that provides ongoing risk analysis is another opportunity to further safeguard operations. Advanced technologies such as Emerson’s high-consequence area (HCA) analysis and risk-modeling software allows users to assess high-consequence areas as well as model and prioritize risk by bringing together data from across the organization into a customizable risk-modeling environment.

Conclusion

As the global economy transforms to lower emission energy sources, one thing is clear – pipelines will become the backbone of infrastructure required for energy transportation.

Supporting our existing, aging pipeline systems today and investing in pipelines for future growth are part of the path to reduced emissions, environmental protection and shifting energy demand provisions.

In fact, some international economies are leading the way in hydrogen generation to support energy grids. With a lower energy density than natural gas, more pipeline capacity will be required to transport hydrogen to markets, and with that reality comes a greater risk of release.

The expectation is regulations and legislation will continue to be expanded, putting greater emphasis on automated leak detection and why it needs to be an integral part of a comprehensive pipeline management strategy.

Comments