August 2022, Vol. 249, No. 8

Features

Spotlight on Mexico: Construction Begins on Tequila Valley Gas Pipeline

By Mauro Nogarin, P&GJ Correspondent, Latin America

(P&GJ) — Mexican’s Corporación CH4 S.A. will carry out the construction of the Camino Real de Tequila Gas Distribution System to distribute high- pressure natural gas to the industrial zone in Tequila.

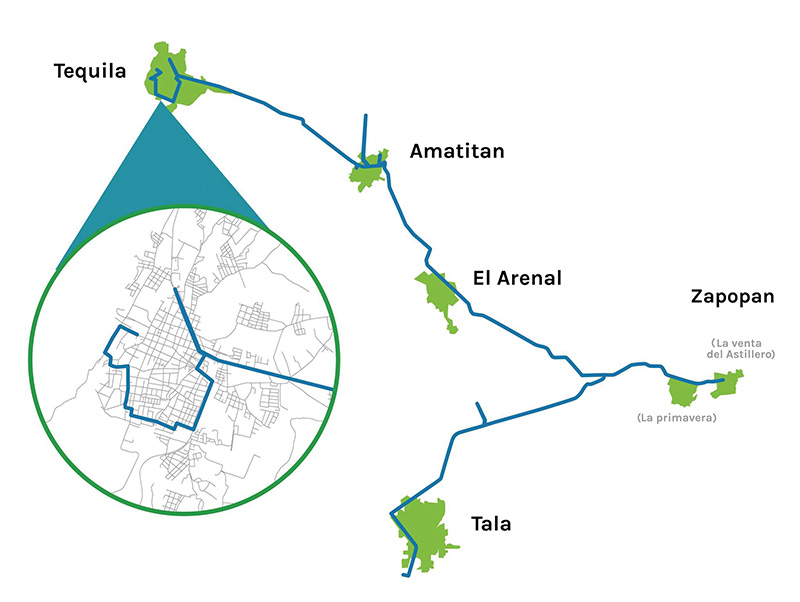

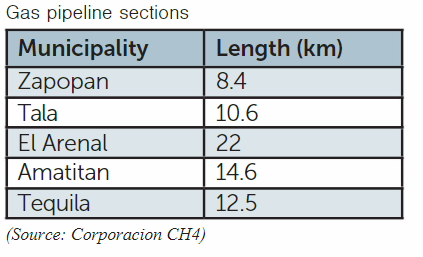

Sited in the Jalisco region, which includes the municipalities of Tequila, Amatitán, El Arenal, Tala and Zapopan, the pipeline will run along the right-of-way of the Guadalajara-Tepic Highway.

Construction begins at the beginning of April and will last seven months, with early operations planned for the beginning of October.

The useful life of the project is 20 years, but because of the nature of the project and its characteristics, the company may request an extension of its useful life, as long as the permits, requirements and procedures are within compliance requirements.

New infrastructure will traverse 42.5 miles (68.5 km) and cross 56 communities and municipalities. It will have distribution branches to private companies that are located along the highway.

The beginning of the distribution network will be at the Oleofinos manufacturing plant, through an 8-inch trunk system that will feed the transportation system. From there, it will go to the facilities of a city gate to regulate the pressure up to 299 psi (21 kg/cm2).

The main section of the gas pipeline will be an 8-inch pipe made of API 5L Grade B/X42 carbon steel with three-layer fusion-bonded epoxy (FBE) anti-corrosion protection.

For construction, engineers of CH4 Corporation will carry out the work in three stages: preparation of the site, construction of the infrastructure and the operation.

The pipeline will be used for the distribution of natural gas to companies in the Tequila industrial zone with a volume of 57,146 gallons per minute (311,500 m3/day) at an operating pressure of 299 psi and a temperature of up to 113 degrees Fahrenheit (45 degrees C).

The pipeline is designed in accordance with ASME B 31.8, the North American industrial standard and the official Mexican standard NOM-003-SECRE-2002 for calculating the thickness of the duct wall, based on the tangential stress and safety factors.

The pipeline will have material certifications with API 5L Grade B carbon steel with nominal diameters of 2, 3, 4 and 8 inches and a hydrostatic resistance of 35,500 psi (2,496 kg/cm2).

After the interconnection at the Oleofinos company, the gas is sent to the Gas Regulation and Measurement Station 1 for filtration, flow measurements and pressure regulation.

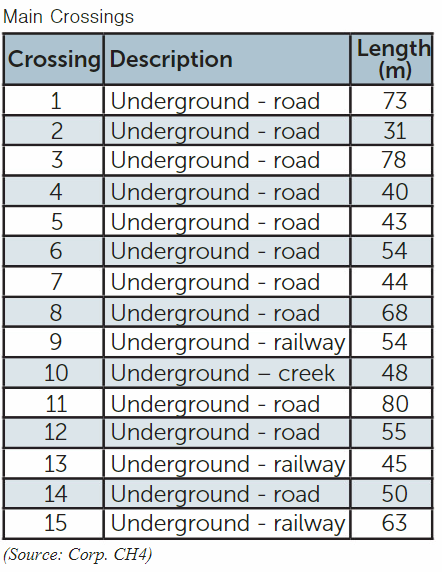

At all crossings, a mechanical protection system will be implemented to protect the pipeline against landslides, floods, unstable soils or landslides that may cause the pipeline to move or be subjected to abnormal loads.

When pipelines cross areas that are normally under water or in areas that are likely to be flooded, an anchor will be applied to prevent movement of the pipeline.

In addition, in general, a mechanical protection coating based on epoxy resin will be applied in the factory and shrink sleeves with a thermal adhesive highly resistant to ground movements will be used in the section joints.

Along the gas pipeline, there will be 14 sectioning valves with a diameter of 8 inches – full bore ball type – where each valve has a pneumatic actuator and a bypass valve to close the flow of natural gas.

The cathodic protection system will involve galvanic anodes or impressed current, in accordance with current regulations and the standards of the National Association of Corrosion Engineers.

Comments