November 2022, Vol. 249, No. 11

Features

Last Line of Defense: Assessing Safety During PE Pipe Isolation

By Ryan Ragsdale, Senior Product Manager, Hot Tapping and Plugging Technology, T.D. Williamson, USA

(P&GJ) — Risk is an everyday part of life for pipeline operators, and controlling risk is a full-time job. Regardless of the operation, risk mitigation relies on many of the same things, including having the right equipment in the right hands, along with comprehensive policies, procedures and training. Yet even with the best procedures in place, individuals are often the last line of defense. Any lapse in human judgment can be the difference between an operation going smoothly and unwittingly introducing a future potential integrity issue.

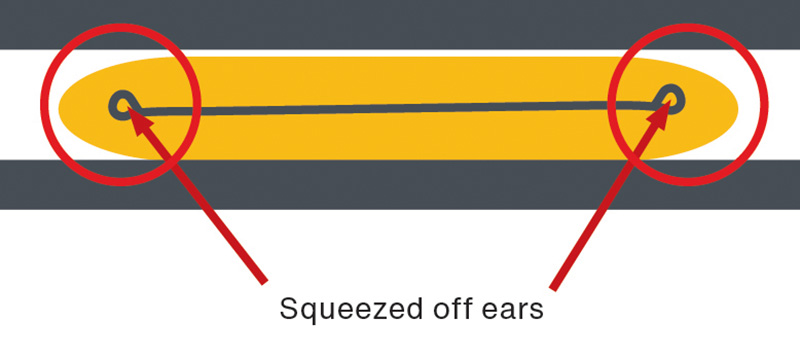

Consider how this might play out during a squeeze off, the most common way to isolate PE pipes.

Squeezing involves using hydraulics or mechanical tools to compress the pipe between two parallel, rounded bars. The process has been applied safely in gas distribution networks for decades, but there’s a caveat: The technician must be careful to follow the prescribed procedure. Any deviation, either by accident or inattention, can negatively affect pipeline integrity, people and the environment.

Fortunately, to date there have been few field reports of squeezing causing PE pipe failure.

Squeezing Older Pipe Can Reduce Useful Life

The industry widely acknowledges that for pre-1983 pipe, squeezing should be considered an unacceptable practice. The concern is that squeezing older pipe can increase the possibility of slow crack growth (SCG) propagation in the stress-concentrated area where the squeeze-off tool is positioned on the pipe. SCG can significantly lower the pipe’s life expectancy.

The U.S. Department of Transportation (DOT) has issued several safety advisories (ADB-99-01, ADB-99-02, ADB-0-07) notifying operators that common PE pipes manufactured prior to 1983 (specifically Century Pipe, low-ductile Aldyl A and PE 3306) are susceptible to SCG propagation, which can be accelerated through squeezing activities.

For newer pipe manufactured using a controlled polymer branching, though, the likelihood of SCG from squeezing is much lower. That’s because the manufacturing process generates a higher density pipe with longer Pennsylvania Edge-Notch Tensile (PENT) test results, meaning it has a longer estimated life and is less susceptible to cracking.

There are certain guidelines operators can follow to reduce the risk of squeezing newer pipes even more, however:

- To maintain the integrity of the pipe, follow proper squeeze procedures per ASTM International F1041.

This includes using the appropriate rate of compression (no more than 5.08 centimeters or 2 inches per minute) and release (no more than 1.27 centimeters or 0.5 inches per minute) as well as the correct squeeze stops to avoid over-squeezing. To avoid damaging the pipe, squeezing should be done only when temperatures are above freezing.

Citing test results and third-party data, most pipe manufacturers and squeeze tool manufacturers warn against deviating from the procedure and include this notice in their operating manuals and on their websites: “If the operator does not follow the approved procedure during a squeeze off, presume the pipe is damaged and replaced or remove from service.”

- Use tools that comply with ASTM International F1563.

ASTM International F1563 covers the physical requirements for tools used to squeeze-off PE gas pipe and tubing.

There is no data suggesting that squeezing newer pipe increases the risk of an incident or decreases asset life when it is done according to those requirements and recommendations.

But just to be sure, T.D. Williamson (TDW), the global pipeline solutions provider, decided to put squeezing to the test.

Proving the Importance of Proper Procedure

TDW engineers performed various squeeze offs on 4-inch medium density polyethylene (MDPE) pipe and evaluated the impact on the pipe using microscopy.

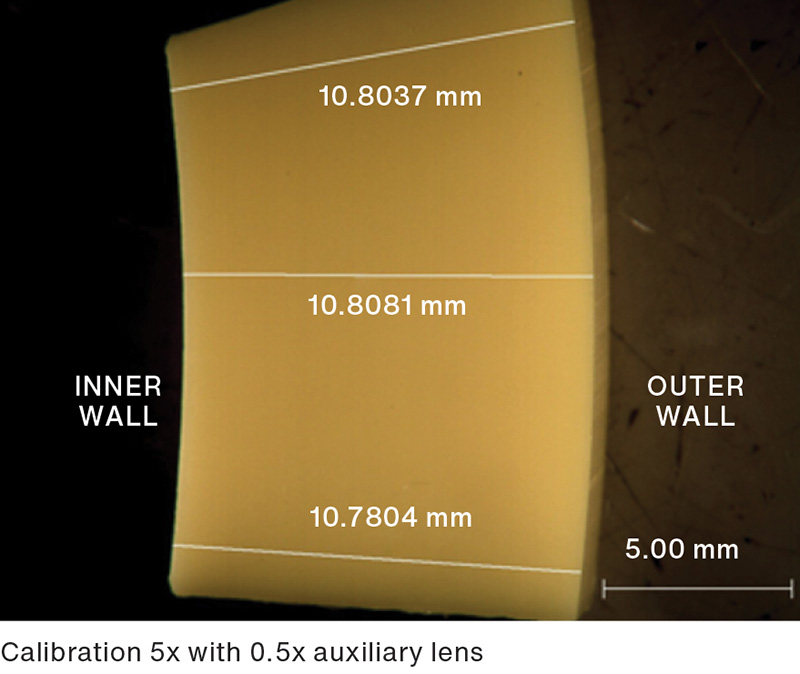

The test began with an ASTM International F1041-compliant squeeze. Before squeezing, the pipe had exceptionally smooth inner and outer walls and no visible deformities. The wall thickness, roughly 10.8 mm (0.425 in), was fairly consistent throughout. Consistent pipe wall thickness is critical to the structural integrity of the pipeline. Any significant decrease in wall thickness could constitute a weakness in the pressure properties and shorten the life of the pipeline.

After the ASTM International F1041-compliant squeeze, there was a small amount of deformation on the inner wall and an approximately 3.7% decrease in wall thickness from about 10.8 mm (0.425 in) to 10.4 mm (0.39 in). There was nothing to suggest the pipe suffered significant damage.

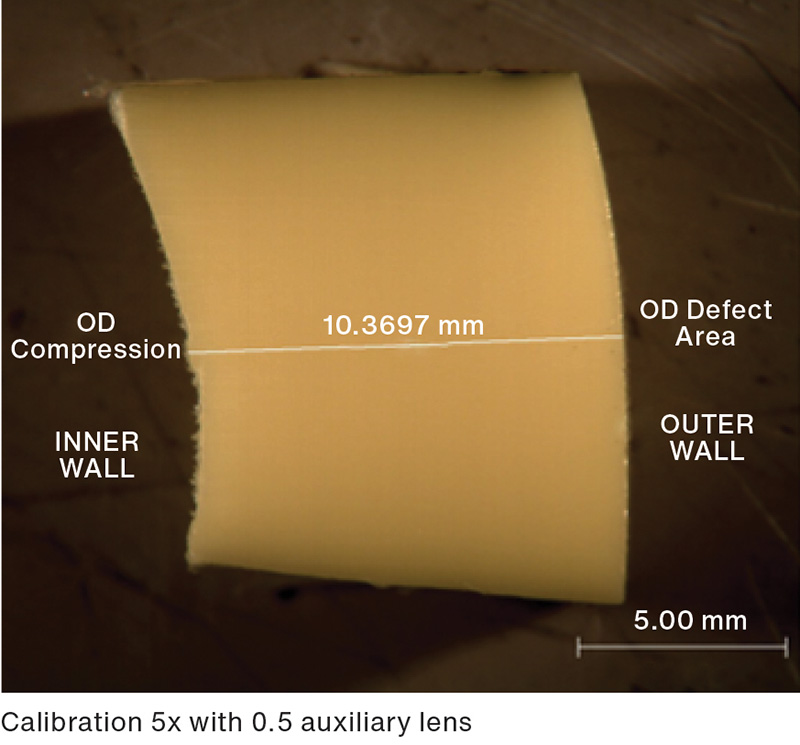

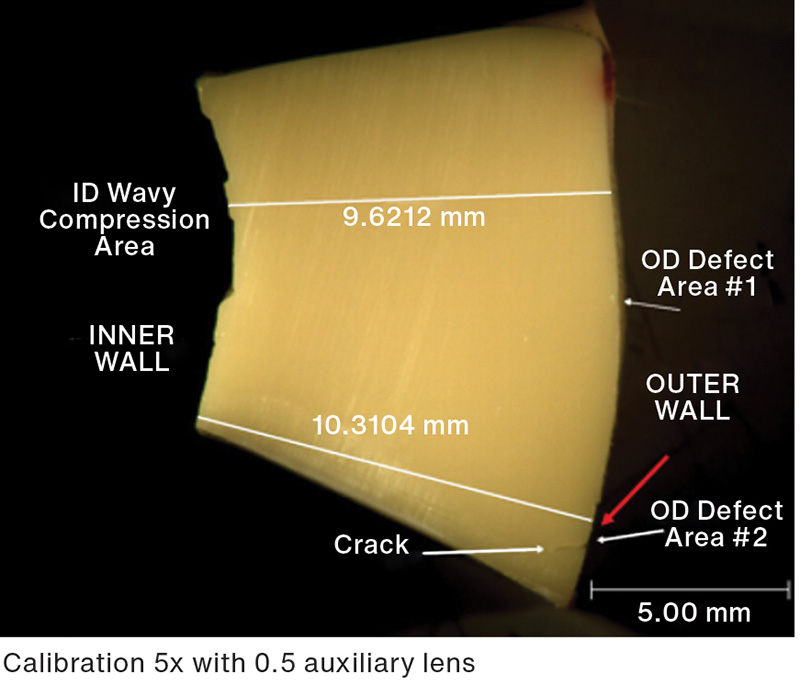

Next, TDW performed a non-compliant procedure on a different piece of the same type of pipe. Engineers squeezed and released the pipe twice as fast as prescribed.

This time, the results were quite different from the first test.

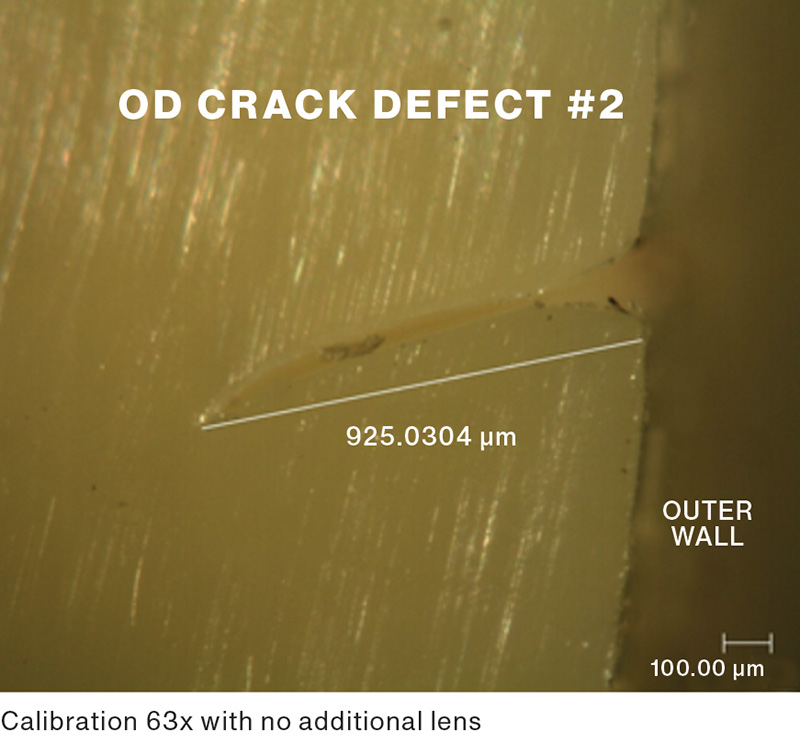

For one thing, there was significant plastic deformation on the inner wall of the pipe as well as a 3.8 cm-long (1.5 in) crack on the outer wall. The crack was approximately 1 mm (0.04 in) deep, or about 8.5% of the total wall thickness.

In addition, the pipe’s wall thickness had decreased about 11%, from close to 10.8 mm (0.425 in) to 9.6 mm (0.375 in).

Given this outcome, should squeezing be considered an unsafe practice?

Absolutely not.

However, this test confirms that following the proper squeezing procedure is critical to the safety, integrity and life of the pipeline. It is up to the technician to perform the proper procedure, but training people to do the right thing the right way may not always lead to the expected outcome.

Engineered Solutions

The squeezing procedure is somewhat tedious and requires diligence to execute properly. It can be easy to unknowingly deviate from the proper procedure. The technician must be consciously monitoring timing during the squeeze and the release, and it can be easy to get distracted and lose track of the process. It is also possible for the worker to use the incorrect stops on the squeeze machine, which could result in an improper squeeze-off.

Currently, certain squeeze tools have controls that eliminate some of the procedural risks, but not all of them.

For operators looking to further eliminate or reduce the risk associated with relying on human behaviors, there is another option: using an engineered physical solution.

Engineered physical solutions have been proven more effective at mitigating or eliminating risks compared to other efforts, including enhancing work practices or depending on human behaviors. According to TDW Sr. Director, Hot Tapping and Plugging (HT&P) Product Line, Ed Guidry, that means it’s generally better to apply a physical change or engineering control to a product than to simply assume that workers will follow a procedure.

“As a service provider and original equipment manufacturer, our goal is always to eliminate or reduce risk whenever possible, and local distribution companies are no different,” Guidry said. “When we have the opportunity to move further up the strength of defenses risk model TDW uses and reduce risk by adding engineering controls, we absolutely want to do that.”

For PE isolation or branching, a line stop fitting is a good example of an engineered solution. Here’s why:

- The fusion process used to attach the fitting to the pipeline increases pressure properties and tensile strength of the pipe.

Interweaving the PE molecules makes the fused area as strong as, if not stronger than, the pipe itself. Once the fusion is complete, the fused area is leak proof. The fitting and the pipe become one and no gas can escape.

PE fitting manufacturers perform destructive testing as part of their design and manufacturing quality processes. They use a hydraulic machine to attempt to forcefully remove the fitting from the pipeline after the fusion is complete, and what they find is that the pipe will break before the fusion is torn away from the pipe.

- Scanning the fitting’s bar codes ensures a successful fusion.

After installing the fitting, the technician scans its bar code. Scanning tells the fusion machine which voltage and amperage to send to the fitting to ensure a successful fusion.

- Recorded results of the fusion process confirm success.

The fusion machine generates a report indicating whether the fusion was successful or there was an error.

- Pressure testing prior to any tapping procedure mitigates risk even more.

Although fusion quality issues are unlikely, testing with a test cap before proceeding with the tapping operation will alert the technician to any problems. If a quality issue is detected, the technician can fuse a new fitting upstream and cut out the bad fitting during the HT&P operation. The key value is that the technician can mitigate the issue before tapping the pipe.

Using an engineered solution doesn’t eliminate the need for proper procedures, of course. In this case, the pipe must be prepared before the fitting can be successfully fused onto it. Preparation includes peeling or scraping the pipe with an approved tool to remove any oxidation on its outer most layers. This is a fairly straightforward step that is neither complicated nor difficult to perform.

Thorough preparation should not be ignored; if the pipe is not peeled before fusion, it is usually because the operator has made an intentional decision to skip this step. This is in contrast to deviating from the prescribed procedure in a squeeze operation, which is more likely to be unintentional. Intentional actions are much easier to correct and control than unintentional actions.

Regardless of the level of pre-fusion preparation, the pressure test with the test cap will uncover issues to be corrected before the fitting is used in an HT&P operation.

Suitable Replacement

To allow an operator to perform PE isolation and branching activities through a fitting easily and safely, TDW developed the POLYSTOPP® Quick Connect system. It incorporates multiple engineered safety features to keep the technician from using the equipment incorrectly. For example, the tapping machine is designed with a positive stop that makes it impossible for the technician to accidentally tap through the bottom of the pipe.

In addition, redundant safety rings and locking collars prevent pipeline damage or personal injury should the technician deviate from the proper operating procedure. If the technician forgets to blow down the housing before removing the tapping, plugging or completion machine, a safety feature ensures equipment position is maintained, thus protecting the operator.

As effective as the POLYSTOPP Quick Connect system is, Guidry said that in the end, the primary concern should be the fitting, since that is what becomes a permanent part of the pipeline. And because the fitting is an engineered solution, it can be considered a suitable replacement for line squeezing.

“Since risk is all around us, safety and quality are our primary mandates,” Guidry said. “By performing isolations with engineered solutions like the POLYSTOPP Quick Connect system, our customers can be assured that they will meet safety requirements and, more importantly, eliminate the risk of pipe damage and offer their teams the security of a truly safe work environment.”

Author: Ryan Ragsdale is a senior product manager, who has been with TDW for eight years and currently oversees TDW’s Isolation portfolio. He is responsible for the strategic positioning and execution of multiple TDW products and is currently leading the design of several products for the gas distribution industry. Most recently, he is overseeing the ProStopp DS and the POLYSTOPP Quick Connect product launches. Ragsdale has a bachelor’s degree and an MBA from Northeastern State University in Oklahoma.

Comments