June 2024, Vol. 251, No. 6

Features

Ensuring Hydrogen-Blend Pipeline Integrity: The Role of In-Line Inspection

By Jeff Sutherland, Products Portfolio Leader, Baker Hughes

[Editor’s note: This is the first part of a two-part article.]

As the globe targets reductions in carbon emissions, the envisaged use of hydrogen as a primary energy medium for nations is underway. Like other energy sources, hydrogen will need to be generated, stored, transported and finally, consumed.

Pipelines are a highly cost-effective method of transportation, and existing pipeline infrastructures are being assessed for their suitability to transport hydrogen around the globe, either as blended within natural gas transport or as pure hydrogen.

The nature of natural hydrogen itself, as an energy medium, brings new considerations in its handling throughout its lifecycle. The use of pipelines as a means of primary H2 transportation directly infers alternative and additional requirements for public safety and pipeline integrity beyond the natural gas hydrocarbon infrastructures of the last 80 years.

There is anticipation within governmental and industry groups to convert and utilize substantial portions of the existing hydrocarbon infrastructure for hydrogen.

Pipeline integrity principles and knowledge — in both conversion of service, as well as ongoing maintenance — may be directly applied in many cases, while others may be adopted with some specific validation. For the purposes here, these principles include threat management practices and known techniques for detection, mitigation, prioritization leading to mitigation (or removal) of a threat.

Such practices also include forecasting pipeline integrity at future points in time, namely through methods for time-dependent flaw growth and remaining life predictions. A primary method in quantitatively assessing both current and forecasting future pipeline integrity states is In-line Inspection (ILI).

We outline this paper in terms of pipeline integrity, threat management practices and the use of ILI within some stated presumptions for the cases of mass-transport of hydrogen in pipelines.

Hydrogen Lifecycle in Energy Infrastructures

The production of hydrogen to date has been for industrial purposes and consumption, including fundamental production of modern chemicals and metals as widely used by society.

A hydrogen-based infrastructure for energy presumes to displace hydrocarbon fuels as a primary distributed source, Figure 1.

Hydrogen does not occur naturally in abundance and would have to be generated either through electrolysis or potentially through chemical processes, such as methane reforming.

Globally, each nation and region have generated similar strategies for clean energy and the role of hydrogen. Each broadly considers generation capacity, role in distribution and usage of hydrogen, in the context of current energy sources and availability. Each strategy also highlights the needs for significant investments in the transition.

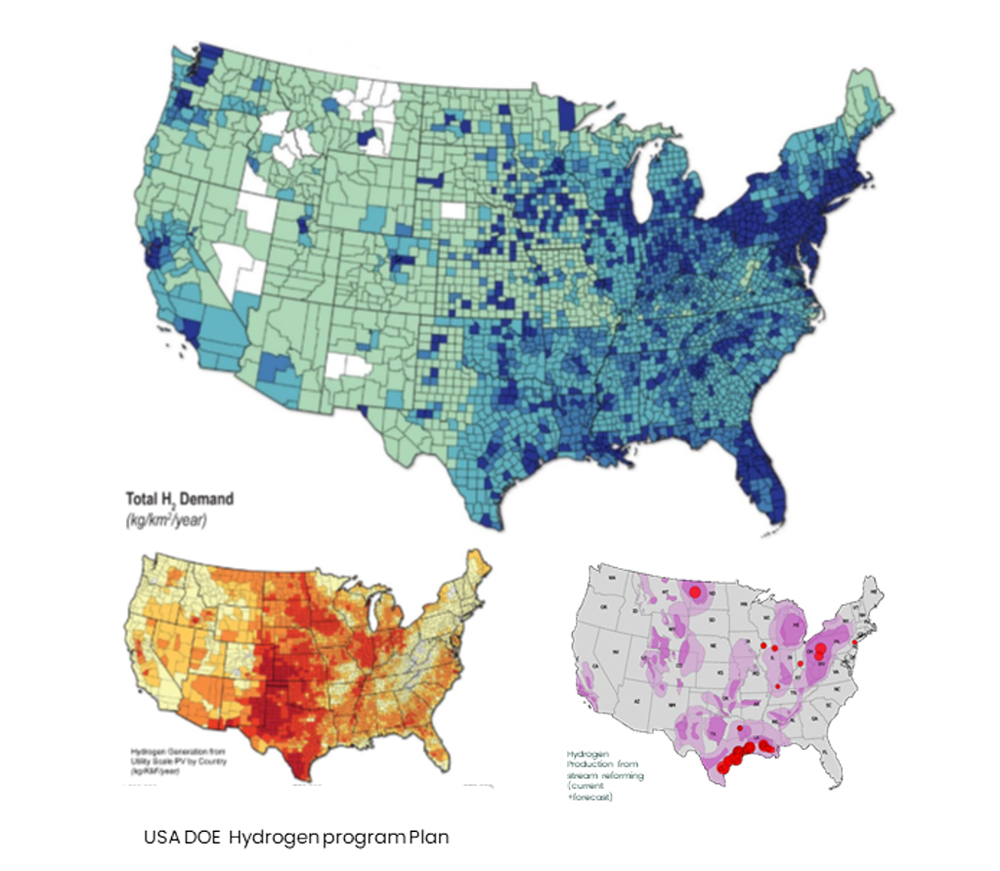

For the United States, the Department of Energy (DOE) has created a strategic program and roadmap for the generation, distribution and use of hydrogen as a primary energy source. [Ref 35,36]. It presumes growth of hydrogen production through assumed future capacities of hydrogen generation through “green” renewables, “blue” reforming and other phased means. It also addresses and presumes a role for Carbon Capture, which is expected to require its own pipeline network for CO2 capture and sequestration. Most prominently, it highlights the need for both social acceptance and broad infrastructure investments.

In 2019, Australia released its hydrogen strategy, which looks at both national energy interests and options for energy infrastructure. [Ref 37]. Australia’s strategy and plan also highlights the possibility of net hydrogen export for international energy markets.

Canada’s hydrogen strategy was published in Dec 2020 [Ref 38], from their Department of Natural Resources. While it addresses similar topics of national energy interests and requirements, it focuses highly on transition opportunities based in existing production industries and energy sectors.

Europe has outlined goals for energy transition, summarized as the EU Hydrogen Backbone [Ref 1]. The infrastructure of this backbone presumes reuse and conversion of its widespread current natural gas infrastructure of transportation pipelines and distribution networks. It also envisages means for Hydrogen storage, including repurposing of existing natural salt caverns as used for hydrocarbons, as well as reinjection of carbon by-products back into depleted hydrocarbon fields (such as under the North Sea).

Depending on the approach and scale to be adopted in generation and usage, a new parallel role has also emerged for Carbon Capture, where carbon emissions by-products (CO, CO2) are to be captured at points of emissions vs being released. Captured by-products will also need their own infrastructure of transport and sequestration, of which pipelines are expected to play a role. [Ref 2,3,4,5].

Such use of Carbon Capture is expected in the definition of blue hydrogen production scenarios, where H2 generation, such as from methane reforming, produces carbon by-products to be captured. It also is expected for any scenarios where emissions from current electrical power generation have carbon by-products (so as to include CO2 transport from combustion to final sequestration).

Descriptors for sources of hydrogen generation have adopted a color spectrum terminology (Figure 3).

The role of transmission pipelines will continue to evolve, including as a means of interim storage, as pipeline networks are redirected according to new generation sources, consumption needs and roles in carbon capture (current hydrocarbon reservoir locations are not presumed to be the same as future hydrogen generation locations) [Ref 6].

As the generation of hydrogen scales up, initial methods considered included blending of hydrogen gas with natural gas, which includes during transport within pipelines [Ref 1,5]. Reported experiences and practices today recommend treating the situation of hydrogen blends as a conversion of service for a pipeline [Ref 6,7,8,9], including an assessment of threats that the presence of hydrogen brings.

Fundamental considerations in a conversion of service are:

- Line pipe materials and assessment for compatibility

- Weld materials and assessment for compatibility

- Compressor stations and components

- Valves and components

- Gaskets (such as at flanges or other joining points)

- Potential threat populations, such as from prior history and integrity programs

- Pipe routing (reclassification of class location, due to population and surroundings of pipeline)

- Preparation, testing, drying to ensure removal of water content with H2 (or C02) present.

In lower H2 gas concentrations within a primarily natural gas fluid, studies have highlighted minor operational differences. In high concentrations, including the 100% hydrogen case, the thermal content of hydrogen gas as well as compressibility has caused studies to infer that higher pressures and higher flow speeds will be required to meet the same energy flow of current natural gas pipeline delivery [Ref 12].

Presumed new pressure levels and operational practices will evolve, though also in accordance with safety considerations. Evolving standards like ASME recommend assuming higher class locations for hydrogen pipelines, as well as specific integrity management processes to consider and factor embrittlement effects on materials (in both line pipe, welds and other components) [Ref 7].

For completeness, some initiatives have started to investigate hydrogen transport and storage in an alternative form, such as ammonia. Ammonia pipelines exist in limited forms today but may be considered as their own type of hazardous material transport pipeline (high corrosivity, toxicity) and thus are not considered here.

Pipeline Integrity

To start with an initial and somewhat alternative premise, for the context of threats for blended hydrogen pipelines, an assumption can be made that threats are any forms of stress concentrators. This premise would include such stress concentrators as classical physical flaws, but they also may be generalized to any localized region where a change in its mechanical or metallurgical properties has occurred.

With hydrogen transportation, the inclusion of threats for areas with atypical compositional or metallurgical properties may need to be considered, even though they are not considered active threats with current hydrocarbon pipeline integrity practices.

Examples include features such as an arc burn, produced by accidental contact with a welding electrode, or a grinding burn, produced by excessive force on a grinding wheel during maintenance. They may also include more distinctive conditions — such as manufacturing impurities (inclusions, laminations) in line pipe — identified as sites for hydrogen permeation and concentration.

The integrity discussion below presumes that there are existing populations of all threats in some form in the pipeline that are unknown until quantified and calibrated through various means (typically from ILI, but also pressure testing or direct assessment/examination modeling).

With geometric, time-dependent flaws, conventional integrity practices would confer a “critical flaw” size that is deemed potentially injurious in near to medium term [Ref 9,10,11]. This approach is applicable for time dependent threats, but cracking will take the focus here. Critical flaw sizes may be determined for given line pipe by establishing a safe pressure target, setting properties assumptions of the strength of materials and using expected operating conditions.

With these criteria and by working through the relevant failure assessment methodology, a flaw can be categorized into an equivalent flaw size as “critical.” Hence, it is presumed that definitions and conditions for tolerable flaw criteria will also achieve consensus amongst stakeholders, while likely being more stringent than today.

The presumption of additional conservatism over equivalent hydrocarbon pipelines, such as for crack and time dependent features in the near term, due to hydrogen embrittlement of the materials, would lead to smaller critical flaw sizes and related acceptability levels (if any) of remaining flaws. If also combined with the potential accelerated growth rates of time-dependent flaws, such exercises then present a need for earliest detection, preferably for smallest features, through regular monitoring activities.

Growth modeling of a flaw itself, with an assumption of simultaneous crack initiation and growth in parallel with the flaw, becomes a tangible scenario. This would include not only corrosion, cracking, deformation and combinations of these, but it would also include external forces (changing over time) coincident with conventional, time-dependent flaws and for regions of alternate material properties.

Susceptibility, Confirmation

The impact of introducing hydrogen into carbon steel pipelines is currently under significant investigation, to establish practical and effective operational conditions and criteria. Understanding a pipeline’s susceptibility to hydrogen induced effects, logically, is recommended to come from conversion-of-service activities or from within fundamental design activities, where a threat/risk model for a given pipeline would be established [Ref 6].

The conditions for susceptibility will have their basis in the threats addressed in natural gas pipeline practices and experiences. This includes known damage mechanisms, such as cracking, corrosion, mechanical damage, deformation and external forces.

If susceptibility for hydrogen embrittlement is treated simply as a “Yes” or “No” for a given location, then the following procedures apply:

- If no, then operators may presume no immediate concern but should engage for longer term monitoring activities, to ensure some level of detection for an initiation at a future time. Scope and threat conditions may be expanded.

- If yes, then operators may presume a given baseline for the pipeline state and an assumed accelerated pace of deterioration for damage mechanisms. Then, integrity planning would factor into an immediate response and mitigation, with lower acceptability thresholds.

Susceptibility considerations must include monitoring for the presence of water (aqueous Hydrogen), as it would be considered a primary factor in steel permeation and embrittlement [Ref 7,11].

An assumption is that the presence of any stress concentrator areas will be immediately addressed, given presumed higher safety protocols and a lower acceptable tolerance for any potential injurious anomalies. In context, such practices and tolerability have similarities in integrity management for sour service and specialty service pipelines.

For “low” count populations of potential flaws, immediate remediation programs to address all reported threats are practical and cost-effective for risk mitigation.

For “high” count populations of potential flaws, additional means of assessments and validation are required to establish criticality and injuriousness within a risk mitigation prioritization framework, which may still involve remediation of all reported threats [Ref 13].

Quantification, Location

Monitoring activities are presumed to include practices such as those from current natural gas practices and procedures. But distinct among those is use of ILI, as a foundational and quantitative dataset across threat types [Ref 6,7]. In previous work [Ref 14], guidance was provided in the form of recommended elements for a reliable assessment based in ILI inspection, including those for future forecasting and remaining life prediction. With some adaptation to terminologies used here, these were:

- A reliable measurement performance for detecting, discriminating and sizing flaws and potential stress concentrators.

- An excavation program with accurate field and laboratory direct observation, to evaluate threat types, calibrate risk/susceptibility models, catalogue characterization of flaws in the pipeline and determine ILI tool predictive performance. This process includes updates to operator practices and threat modeling, as well as providing reliable data feedback to the ILI vendor for improvements — particularly for non-conventional flaws and conditions.

Comprehensive flaw assessment methodologies — particularly fracture mechanics-based methods with representative material properties data — ought to be used for prioritizing excavations and future life cycle/re-inspection intervals prediction.

Damage Mechanisms

Cracking

Practices for crack management threats were initiated for liquid lines, where pressure-cycling and material fatigue are prominent. It quickly evolved to gas pipelines as well, with external cracking mechanisms being formally classified (SCC – Stress Corrosion Cracking), in addition to being independent of internal pipeline product.

CEPA [Ref 15] and API 1176 [Ref 11] address multiple forms of cracking that have factored hydrogen into different cracking formation mechanisms. It is presumed that flexure stress (fatigue) is present in the presence of initiators or impurities in the line pipe material (or weld) as a concentrator site for hydrogen, which leads to cracking.

A very fundamental point is the notion of the crack feature as a material “discontinuity,” especially with a population of those features present in the pipeline as “growing discontinuities.” With this point in mind, see Figure 4 for a crack growth lifecycle. Modeling of cracking growth presumes a multi-stage “bathtub” behavior, as originally stated by Perkins and adopted by CEPA and API [Ref. 15, 11].

For external cracking and initiation, current cracking (SCC) stage timing remains as is for current hydrocarbon pipelines. For hydrogen influences as the internal source, it is (conservatively) assumed that an acceleration through the stages will occur as compared to hydrocarbon influences, as hydrogen may permeate within the material (as line pipe or weld) from the inside to the outside.

In comparison, SCC (external) conditions for Stage 1 are typically mediated through corrosion control practices. However, crack initiation may still occur.

Of note is Stage 2, where crack growth is “mechanically driven” and assumed in the presence of hydrogen embrittlement. Key conditions include stress-dependent loading interactions and frequency, where the crack is growing at its fastest rate. Growth mechanism modeling may factor in the localized stress state at a crack tip.

By Stage 3, rapid crack growth of sizable cracks occurs, and failure is imminent. Remediation and integrity management measures are expected to be taken prior to reaching this stage.

In context, H2 has always been a factor in SCC susceptibility, particularly for aqueous hydrogen, but with SCC, it presumes direct contact of the external surface of the pipe with the presence of water. Crack threats are categorized broadly within environmental cracking (including Hydrogen-induced cracking), fatigue cracking and SCC. API outlines an inclusive list of conditions (all must be present) for H2 effects to be applicable. These are: poor coating state, water presence (internal or external), high CP potentials, known high hardness material values and higher observed crack growth [Ref 11].

Cracking definitions have typically been defined around the formation mechanism of the cracking, as it evolved out of the susceptibility model for conditions to be monitored. However, the physical embodiment of the crack itself is what factors into the (fracture mechanics) assessment for integrity [Ref 18].

Recent efforts in the transition to hydrogen pipelines have focused on the threat of cracking, due to the potential embrittlement of the material caused by the presence of hydrogen itself. Comprehensive fracture mechanics methods consider pipeline material properties, with material toughness being a primary factor for and influence on the sensitivity of results and the determination of severity and risk.

One study, looking specifically at the EU gas transmission network, concluded that around 70% of European pipelines are API 5L Gr. B, X46 or X52 — steel grades that are expected to show good compatibility with hydrogen transport without modification [Ref 16].

However, findings by Sandia National Laboratories, on behalf of the U.S. Department of Energy, reported that the deterioration of fracture resistance in pipeline steel is unrelated to the concentration of the hydrogen blend in the pipeline. At a given pressure, the proportion of fracture resistance lost at 1% H2 blend was also like that for 100% H2 [Ref 17].

At any time through the pipeline operating life, there is the potential for conditions to initiate for cracking; hence, susceptibility assessment and active monitoring have been recommended practices.

Editor’s note: This paper was first published at the 36th Pipeline Pigging and Integrity Management Conference, February 2024. Organized by Clarion Technical Conferences. Used with permission.

Comments