April 2011 Vol. 238 No. 4

Features

New Challenges Drive R&D At National Grid

We all know the traditional drivers for gas operations R&D: 1) aging infrastructure, 2) better leak detection and repair, 3) trenchless technology, and 4) better methods of live inspection and repair. In more recent times, pipeline integrity and damage prevention concerns have been the focus of much innovation and materials research – primarily on plastic pipe. This has been and will continue to be a research goal.

But times are changing and the gas industry must react. Better yet, it must lead into new technology areas. Issues such as climate change and the changing gas supply picture are real and they are here now. National Grid is leading and driving innovation in these areas. National Grid is an international electricity and natural gas company. The company’s core business is the delivery of electricity and natural gas.

Climate Change Is Real

National Grid and others recognize that climate change is real and is most likely due to increased levels of manmade greenhouse gas (United Nations Intergovernmental Panel on Climate Change Reports 1990–2007). At National Grid we focus on climate change from two aspects: 1) how can we reduce our impact on the environment, and 2) how can we best deal with expected climate change effects and impacts to our business and our infrastructure.

Working through the NYSEARCH and Operations Technology Development (OTD) research consortia, the company is funding and driving research and new technology to address these issues.

The company is committed to measuring and reducing our own greenhouse gas (GHG) emissions. For a gas distribution system that commitment translates into reducing methane leakage from our piping network. But how much is actually leaking? Current methodology for calculating leakage is to apply 15-year-old emission factors (leakage per mile of pipe or per service) to the current inventory of pipe and services. But these leakage factors are based on a limited sampling program and do not take into account the improvements made to our systems over the past 15 years. They also don’t account for any leak-repair activities.

Working with OTD, a collaborative research organization representing gas utilities throughout North America, National Grid and others are updating the emission factors to more accurately represent the current state of our systems.

Plastic pipe manufacturing and joining techniques have vastly improved since these factors were developed, and the bulk of new piping added to distribution systems is plastic. The company believes that our plastic pipe network is not contributing as much to our carbon footprint as the factors may suggest, so the first phase of this research focuses on developing more accurate emission factors for plastic pipe. Future phases will look at other pipe materials such as cast iron and unprotected steel. Although we are removing these materials from our system we still want to produce a more accurate annual inventory.

Through NYSEARCH, the North American research organization administered by the Northeast Gas Association, the company is looking at improvements to live gas tapping operations to reduce the amount of blowing gas. In addition to reducing our impact to the environment, these improvements can eliminate the need for workers to don fresh air breathing apparatus while performing these operations.

But the natural gas distribution industry contributes less than 2% annually to U.S. greenhouse gas emissions (USEPA 2010 Greenhouse Gas Inventory). So even if the company does its part to measure and reduce its own emissions it is still faced with the future effects and impacts of climate change.

What are those effects? Working with NYSEARCH and other gas LDCs in the northeast U.S., the company sought answers to the following questions: 1) how will the climate change by the year 2025? By 2050? 2) How will this projected climate change translate into impacts to our natural gas infrastructure, and to our business (supply and demand patterns)? 3) How do we quantitatively evaluate the risk to our business and infrastructure? 4) What actions might we take to mitigate those risks?

URS Corp., under contract to NYSEARCH, recently completed a Phase I study examining these issues. URS summarized projected climate change effects, primarily sea level rise, average temperature, precipitation patterns and frequency of storms, under different GHG emission scenarios. (The more GHG emitted the more severe the climate impacts will be.)

Next, impacts on the business were listed, including potential impacts to supply, demand and infrastructure. Although a detailed risk analysis was not performed (that was beyond the scope of the Phase I effort) a framework or model for risk analyses was presented. Results of this Phase I work are broad – covering the territories of all the funders (seven LDCs covering the states of Pennsylvania, New York, Massachusetts and New Hampshire) – and National Grid is evaluating a future phase which would focus more directly on our service territory.

Our Changing Supply Picture

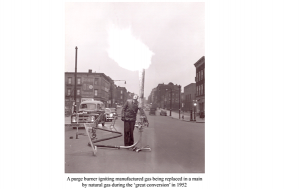

Our gas distribution industry is entering “the second great conversion.” The last major change to the industry’s supply picture occurred in the ’50s with the conversion from manufactured gas to pipeline gas from the Gulf region. We are now dealing with, and planning for gas supplies from the following diverse sources: 1) western Canada, 2) eastern Canada, 3) revaporized LNG from foreign sources, 4) shale gas from various sources throughout North America, and 5) renewable gas (biomethane) from various sources.

Heating value, heavy hydrocarbon content, increased concentration of nitrogen and other inerts, and trace constituent concentrations can be expected to vary, sometimes significantly from what we are used to seeing from our pipeline suppliers. National Grid wants answers to the following questions: 1) what is the effect of the changing supply picture on our infrastructure and its components? 2) What is the effect on residential appliances, many of which are at least 15-20 years old? 3) What standards ought to exist for renewable gas from dairy or wastewater streams?

The company is participating in and leading work across several fronts in this new important research topic.

A broad consortium of LDCs throughout North America is working through NYSEARCH to answer the question of gas composition effects on infrastructure components. Working with the Gas Technology Institute (GTI), the project team identified components of concern, mostly non-metallic materials that are found in gaskets, seals, diaphragms and o-rings. Next, a range of test gases was identified that represent current and expected supplies throughout all the project funders’ service territories.

Meeting the needs of all 16 project funders was challenging but consensus was reached and a test program was designed by GTI. Test gases were procured, suspect components were removed from the field by participating LDCs and testing is under way in GTI’s environmental testing facilities in Chicago. The test program cycles the components through a range of pressure, temperature and varying gas compositions to identify which materials may be susceptible to which gas compositions. The test program is still under way.

Again working with NYSEARCH and a broad industry consortium, National Grid and others want to determine whether changing gas supplies may have an effect on a broad population of installed (as is) residential appliances. A three-part paper and field study was crafted and, in the first phase, patterns of appliance types and installation and manufacturing practices for the study areas in question were analyzed.

The field-testing portion of the project involved an in situ analysis of more than 2,000 appliances for performance, and comprehensive follow-up lab testing on selected appliances fired with a range of test gases selected by the funders. Results from both these test programs will provide LDCs with a comprehensive knowledge base rooted in rigorous field and lab testing to allow intelligent choices in dealing with a wide range of expected future gas supplies. These choices could include 1) maintenance recommendations, 2) component removal or remediation, or 3) setting new supply tariff limits.

Another phenomenon that seems to be related to the increased use of non-traditional sources of natural gas is odor masking. Different from odor fade (which is a measurable reduction in the amount of odorant in a pipeline) odor masking is a physiological change in the ability to detect odorant because of interactions with various trace constituents in natural gas. In short, the characteristic odor of gas can disappear, only to reappear for reasons not completely understood. The National Institute of Standards (NIST) is starting some work to understand this phenomenon and, through the NYSEARCH consortium, National Grid and others will participate in and supplement this research with some specific testing.

The company and others are also working with GTI to more fully understand the odor fade phenomena. It is thought that new or non-traditional gas supplies could be contributing to odor fade incidents. A testing program at GTI will test for this as well as other contributing factors to odor fade occurrences.

Sustainable Gas

Sustainable gas, also known as renewable gas or biomethane, is pipeline-quality gas that is derived from various waste streams such as municipal solid waste, livestock manure, or agricultural waste. The company supports the concept of renewable gas because its use will reduce GHG emissions and contribute to diversity of supply. High-end estimates show that renewable gas could possibly meet up to 25% of the company’s natural gas demand. Research is under way on several fronts to address technical concerns related to the development and use of renewable gas. Although renewable gas has been used for electric power generation, the introduction of renewable gas at a burnertip in a home is a different matter; that gas needs to be of a quality fully interchangeable with pipeline natural gas. The company has been injecting renewable gas from a landfill for 30 years now, but the time has come for national standards to be developed.

Working across the industry, National Grid and others commissioned GTI to develop guidance documents on the use of sustainable gas in our distribution networks. GTI carefully studied renewable gas production from two separate and distinct feedstocks: dairy waste and municipal landfills.

Initially, the state-of-the-art in renewable gas production from dairy waste facilities was studied, both domestically and abroad. GTI then conducted comprehensive lab testing for more than 300 chemical species in renewable gas samples from two separate sites. Six biological assays were also conducted and determined that, with appropriate cleanup technologies, renewable gas from dairy waste streams can meet pipeline tariffs.

Similar work is under way to analyze gas streams from landfills. The range of constituents in landfill gas can be large. In fact, one industry observer has likened it to the periodic table! In addition to hydrocarbons, sulfur compounds and inerts, other constituents such as vinyl chlorides, siloxanes, ammonia, and bacteria, can be present.

Also, trace elements such as mercury and others can exist in microgram per cubic meter concentrations. Samples will be collected from landfills throughout the U.S. that are producing a high Btu gas for pipeline injection or transportation fuel. Again, the aim of this research is to prove that renewable gas from landfills can be safely introduced into distribution networks.

Based on the results of these two renewable gas projects, other work is being considered related to acceptable limits for siloxanes (silicon-based compounds that can clog heat exchanger components) and other trace constituents that could pose problems.

Natural gas is an environmentally friendly and domestically abundant energy source. Its use will increase as the nation takes action to reduce carbon emissions and achieve energy security. Research and technology development must expand and adapt so that our industry can contribute to meeting these dual goals. National Grid and our research partners are proud and excited to be part of this changing energy landscape.

Author:

Joseph M. Vitelli Jr. is a principal engineer in National Grid’s Gas Engineering Policy RD&D Group where he is involved in various operational technologies such as robots for inspecting unpiggable pipelines, new generation pipe locating technology, new pipe materials, new methods of pipe repair, development of new NDE methods for plastic pipe and other gas distribution technologies. He also is the “Climate Change” coordinator for the company’s U.S. gas distribution business. He has a bachelor’s degree in mechanical engineering from Manhattan College and a master’s degree in nuclear engineering from Polytechnic Institute of New York. He is a licensed New York State Professional Engineer. He can be reached at Joseph.VitelliJr@us.ngrid.com.

Comments