July 2012, Vol. 239 No. 7

Features

Coriolis Mass Flow Meters For Bulk Measurement

Accurate measurement of liquids is important for all oil and gas industry production or consumption sites. This is especially true for bulk transfer devices where large volumes of products are being moved and must be monitored, including crude oil pipelines, depots, gasoline and jet fuel tank farms, refineries and even cruise line terminals.

In the past, mass transfer was measured in batches with weigh scales or load cells. However installation, calibration, and maintenance of a scale or load cell are costly, difficult to do, time consuming, and don’t work for continuous processes. For these processes, such methods as orifice plates and magnetic flow tubes can measure volumetric flow, but additional instruments are needed to measure temperature and pressure to compensate for fluid density changes. Introducing additional instruments also introduces errors, which can result in an overall measurement error rate as high as 3%.

Now, several measurement standards are moving toward use of Coriolis mass flow meters, which can measure mass flow directly, at the same time as they measure temperature and density. What’s more, transfer measurement by mass is the most accurate method, since mass is independent of, and unaffected by, changing process fluid characteristics, including pressure, temperature, viscosity, conductivity, and gravity.

Among the Coriolis devices available, the straight tube design is being hailed as the most accurate and easiest to install and maintain. Especially for measurement skids, widely used in the oil and gas industry, the straight tube Coriolis meter can be a factor in minimizing skid size.

The Coriolis Effect

What is the effect and why does it help with bulk measurement? In physics, the Coriolis effect is a deflection of moving objects when they are viewed in a rotating reference frame. In a reference frame with clockwise rotation, the deflection is to the left of the motion of the object. In a reference frame with counter-clockwise rotation, the deflection is to the right. The mathematical expression for the Coriolis force appeared in an 1835 paper by the French scientist Gaspard Gustave Coriolis, in connection with the theory of water wheels. [1]

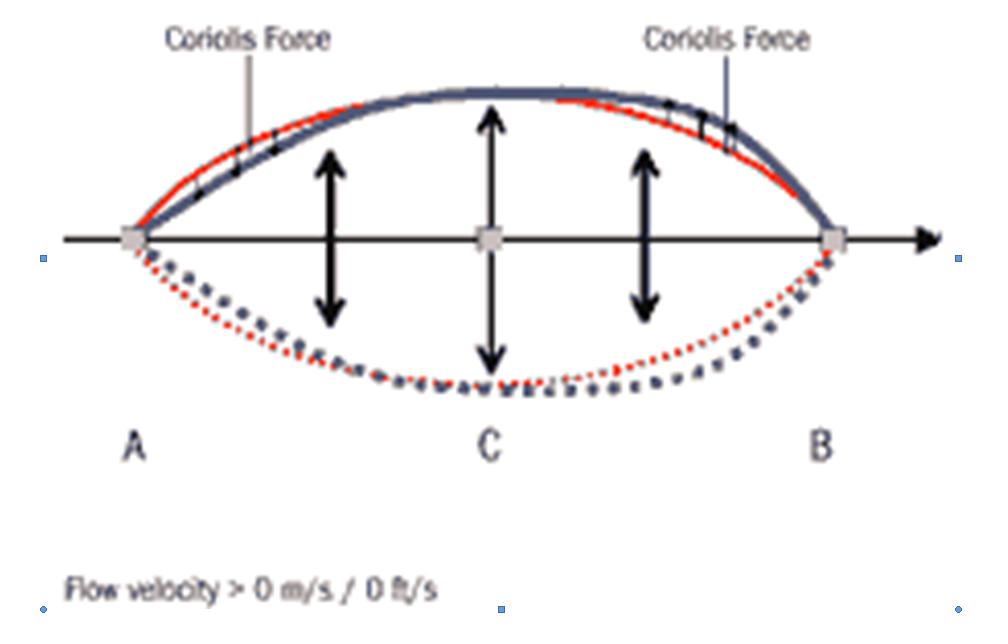

Figure 1 provides a simple overview of a Coriolis measuring system, which makes use of the effect by using a symmetrical design consisting of one or two measuring tubes, either straight or curved. [2] A driver sets the measuring tube (AB) into a uniform fundamental oscillation mode.

When the flow velocity (v) equals 0 meters/second/0 feet/second (0m/s/0ft/s), the Coriolis force (Fc) is also 0. At flowing conditions, when the flow velocity (v) > 0 m/s/0 ft/s, the fluid particles in the product are accelerated between points AC and decelerated between points CB.

The Coriolis force (Fc) is generated by the inertia of the fluid particles accelerated between points AC and of those decelerated between points CB.

This force causes an extremely slight distortion of the measuring tube that is superimposed on the fundamental component and is directly proportional to the mass flow rate. This distortion is picked up by special sensors. Since the oscillatory characteristics of the measuring tube are dependent on temperature, the temperature is measured continuously and the measured values corrected accordingly.

In a dual-tube Coriolis meter, a manifold splits the flow through each of the two tubes. The full flow always goes through the sensor. The two vibrating tubes rotate around the two fixed end points, creating a Coriolis effect when mass flows through.

Mechanical Meters

Measurement of petroleum fluids has been around for hundreds of years and has been performed fairly reliably with the use of a wide range of mechanical meters.

One significant drawback to mechanical meters is that they experience serious wear and tear, and can be plagued by high maintenance costs and the need for frequent replacement parts.

Mechanical meters have to be calibrated on a single grade, making recalibration, also known as meter proving, necessary each time a different product is measured. For example, suppose a facility is handling crude oil from Venezuela one day and from Texas on another day. Since these have a different fluid basis, the meter would have to be re-proved since the meter’s calibration factor is affected by a variety of fluid conditions, especially density. Custody system operators often need to use a prover for measuring one batch to another, reproving for every different fluid transaction.

All of this comes with a time and money cost. Usually, the facility operator outsources these activities, which adds to the cost of running the facility.

Advances in manufacturing technology have led to the recent ability to make Coriolis meters in larger sizes, making them viable for oil and gas applications that have heretofore been the domain of mechanical meters. Coriolis meters have no moving parts, so they have fewer parts to maintain. Also, unlike mechanical meter measurements that are used for custody transfer which have to be corrected using pressure and temperature compensation, the Coriolis meter measures product mass directly, independent of pressure and temperature.

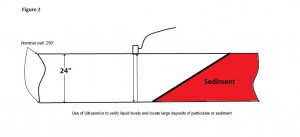

Direct mass flow measurement with Coriolis mass flow meters means that one flow meter with a single point of measurement can obtain multiple measured values, including mass flow and mass total, density and concentration, volume flow and volume total, and temperature. It also reduces overall costs because there is only a single instrument to buy and maintain, cables and power consumption are reduced, and controls are simplified. Figure 2 shows a graphic portrayal of a system that could be used for volumetric flow measurement.

Figure 2.

Reduced Pressure Drop

Reduction in pressure drop is one of the important differentiating factors between mechanical meters and Coriolis mass flow meters. Pushing fluids past a mechanical meter always creates a pressure drop which is not recoverable. Every time one imposes a pressure drop, it must be overcome with the use of a pump.

With a Coriolis mass flow meter, there will be no extra pressure drop across the meter. In most meters there are twin tubes and the only pressure drop is caused by splitting the flow into the two pipes inside the meter. Using the straight pipe Coriolis meter design creates less permanent pressure drop than the bent tube variety.

Accuracy is another important benefit gained with the use of the Coriolis meter. The vast majority of operators using mechanical flow meters are also running separate pressure and temperature meters. Say the mechanical flow meter exhibits a 0.5% accuracy error, the pressure meter also poses a 0.5% accuracy error, and the temperature meter a further 1%. When those values are combined in a flow corrector or computer, the overall calculated error rate could be 2% or higher. Plus, since each instrument drifts over time independently, accuracy would be further degraded, perhaps to as high as 3%. The Coriolis meter’s error rate is only 0.1 to 0.2% of rate, making it nominally five to ten times more accurate and its long-term drift is minimal as compared to devices with moving parts.

In addition, the Coriolis meter is easier to install and maintain. Especially for measurement skids that may have to fit into a relatively small footprint, the straight tube Coriolis meter takes up the smallest space with simple process piping. The straight tube design is considerably easier to clean than the bent tube version, which tends to get deposit build up on the tube, and much simpler than equivalent mechanical meters which would also require strainers and filters upstream. Figure 3 shows how the meter would fit into the measurement skid.

Figure 3.

A final benefit is the electronic controls, which provide more flexibility in terms of operational performance. Operators can view everything that is going on with the fluid, including volumetric flow, mass flow, density, and temperature. Most have options for multiple outputs, including digital converters that allow for direct MODBUS to see all the parameters. The available controls can ensure that the correct product is going through the meter, make sure product is drawn from the right tank, or tell the operator if the product is hotter or cooler than expected. More flexibility allows operators to maintain tighter control, which ultimately leads to less waste.

Ontario Refinery

At one petroleum refinery site in Ontario, Canada that produces refined gasoline, jet fuel and other petroleum products, the operators ship and meter product through a 5-km, 8-inch pipeline that connects to a major Canadian pipeline, which in turn delivers the product to the Greater Toronto area. They needed to measure the product leaving the plant site and the product going to the shipping pipeline, and wanted a density reading at the same time. The refinery ships different products through one line and had to confirm that they were shipping the correct product.

The pipeline was large, the available real estate in the existing location was limited, and they did not want to do a large-scale modification to install additional structural support for meters. They also wanted to limit pressure drop through the meter to avoid wasting energy and reduce the energy cost of running the pipeline.

The facility looked at various types of metering technologies, including ultrasonic, vortex shedding, and orifice plate meter, but ultimately chose a Coriolis mass flow meter, in part because they could get flow and density measurements from one device, making it possible to fit the device into their tight space.

Facility operators evaluated the use of both straight tube and bent tube Coriolis meters, and considered products available from several vendors. Cost of the two meter designs was equal, but installation costs for the straight tube meter were significantly lower. The straight tube design offered lower pressure drop and was less subject to plugging, but most importantly, it was simpler to install and took up less space than competitive options that were larger footprint devices.

They initially had reservations about selecting the straight tube design because bent tube is the more traditional choice and there is a larger installed base for that design. However, they ultimately chose a straight tube OPTIMASS 2000 Coriolis meter (Figure 4), based on the meter’s lower installation costs, combined with its high accuracy and linearity, as well as the longer than usual three-year warranty. In addition, the price included extensive onsite startup support. This support during the installation process was one factor that enabled the Canadian refinery to successfully install the straight tube Coriolis meter.

Figure 4(a)

Figure 4(b)

The refinery makes use of the communication options to monitor the meter remotely from a laptop. Also, the meter’s sensor has its own built- in smart sensor interface and on-board memory, so the electronic converter/transmitter can talk directly to the sensor digitally. As shown in Figure 4, the two installed devices are remote and segregated while sharing device configuration data, so if there is a problem with either the sensor or the transmitter, authorized technicians can replace one or the other independently and sensor calibration files or converter parameters can be uploaded from either device, adding to the meter’s reliability.

Custody Transfer

The evolution of the design of Coriolis mass flow meters means they can now compete better with traditional mechanical meters. For the bulk measurement of any fluid with a significant value, large diameter Coriolis mass flow meters offer more accurate and repeatable bulk fluid transfer measurement. Further, the straight tube Coriolis meter design offers the lowest pressure drop and highest accuracy.

References

[1] http://en.wikipedia.org/wiki/Coriolis_effect

[2] http://www.krohne.com/Measuring_Principle_Coriolis_Mass_Flowmeters_en.730.0.html, retrieved June 20, 2011

Comments