September 2014, Vol. 241, No. 9

Features

Best Estimates: Developing New Quantification Protocol For Methane Emissions Reduction

Aggressive efforts are underway to reduce methane emissions from the natural gas sector and the industry is working on technologies and approaches for mitigating emissions. But it also must improve the way emissions are quantified. By establishing reasonable baselines, utilities will be able to provide more accurate reports about their emissions profiles and implement mitigation and reduction programs. GTI and its industry partners are working to update those baselines now.

As the role of natural gas grows in importance as a segment of the nation’s energy portfolio, the natural gas industry is stepping up its efforts to reduce methane emissions. Going forward, however, the industry faces significant challenges in determining how leaks are measured and quantified, as well as in determining how data will be used to drive leak-mitigation strategies.

“It’s important for us to help the industry better quantify its methane emissions profile and incorporate this data into an overall mitigation strategy that puts safety and the environment at the top of the priority list,” said Paul Armstrong, director, business development at Gas Technology Institute (GTI), a leading research and development organization serving energy industries. “GTI understands that this is a critical issue for the natural gas industry as a whole and that each industry sector has its own unique challenges that must be addressed.”

The Big Picture

Reduction of methane emissions has become a high-profile national issue, with many environmental groups and government agencies calling for action. Most recently, the Obama administration announced a new “Strategy to Reduce Methane Emissions” as part of its Climate Action Plan. A number of environmental advocates and federal agencies – including the EPA, Department of Energy (DOE), and Department of Transportation (DOT) – are already working to execute the strategy.

For example, the EPA is proposing the Gold Star Program, an addition to its successful Natural Gas STAR Program, which will recognize operators that implement protocols to further reduce methane emissions “through available, cost-effective technologies.” The agency also recently released a series of white papers focused on potentially significant sources of emissions in the oil and gas sector.

GTI is working closely with the EPA’s Greenhouse Gas Inventory reporting program to encourage adoption of updated emission factors (EFs) that resulted from recent field projects. Additionally, GTI has participated as a panelist at the request of the DOE in stakeholder roundtables which will set the stage for the nation’s emissions reduction agenda and strategy.

GTI is also involved in the development of technologies to support emission-reduction strategies through collaboration with industry partners. Most recently, the DOE’s ARPA-E (Advanced Research Projects-Energy) program announced its new MONITOR program, which will fund the development of low-cost, highly sensitive systems for detecting and measuring methane associated with the production and transportation of oil and natural gas.

What’s Happening In The Distribution Sector?

When it comes to methane emissions from the natural gas value chain, how does the distribution sector stack up? The EPA estimates an effective natural gas emissions rate-per-unit of natural gas production of 1.5%. According to the EPA and the Energy Information Agency (EIA), only 0.3% of those emissions (20%) are from systems operated by local distribution companies (LDCs). Yet, even though they represent a relatively small percentage of total industry emissions, utilities are actively seeking ways to reduce their emissions.

For the industry to accurately quantify its emissions footprint, it will be important to improve the quality of data used to calculate those emissions. Traditionally, in their methane emissions reports to the EPA, natural gas utilities have used national emission factors (EFs) derived from a GRI-EPA study published in 1996.

While that study was one of the first industry efforts to develop a national methane emissions inventory, it was not intended to be used by individual companies in their reporting. According to Pamela Lacey, senior environmental lawyer at the American Gas Association (AGA), the study “served its purpose at that time, but procedures and equipment have changed significantly since then. The old study no longer provides an accurate picture of current practices and emissions.”

And because each system is different, “the actual emissions of any one system might be higher or lower than what the existing calculations would lead you to believe,” said Kristine Wiley, senior scientist at GTI.

Improving Emissions Estimates For Distribution Systems

Since 2009, GTI has taken the lead in addressing the gaps in determining a real emissions baseline for the distribution sector, leading a multi-phase project designed to develop a methodology that can provide a greater level of accuracy. “Our research focuses on measurements from gas distribution systems – specifically, leaks from main and service pipelines,” said Armstrong.

“We’re trying to improve the accuracy of reporting methane emissions with this series of projects,” said Wiley, who leads GTI’s methane emissions initiative.

The first phase of the project, completed in 2010, focused on developing a new field technique to measure emissions. Researchers field-tested and validated a new approach to measuring methane emissions at the surface using the Hi-Flow Sampler, a portable device that provides real-time measurements of gas flow rates and concentrations in a captured enclosure. The GTI team evaluated surface measurements in various site conditions, correlating them to belowground measurements in isolated pipe segments. By enabling aboveground measurements, the Hi-Flow Sampler provides greater efficiency for collecting additional data.

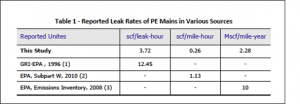

In the second phase of the project, the GTI team set out to update the national EF for plastic pipe. Expanding the dataset beyond that of the original 1996 GRI study, the GTI testing program provided a new national EF estimate of 3.72 scf/leak-hour for PE mains, lower than the historic GRI-EPA EF estimate of 12.45 scf/leak-hour. The project demonstrated that the actual EF for PE pipe is about 70% lower than the earlier estimate (in scf/leak-year) and is much more representative of plastic distribution systems.

“It is also an example of how obtaining current data and using a bottoms-up approach is very important when quantifying emissions and identifying mitigation strategies for reducing emissions,” said Wiley.

The team converted the EF estimate to a mile-year basis for a direct comparison to data in the EPA GHG inventory, as shown in the table below.

Emissions are measured in terms of the average amount of a pollutant or material discharged into the atmosphere by a particular process or equipment (e.g.,2.28 Mscf/mile/year for PE mains).

A New Methodology

Subsequent phases of the project continued the field test program for cast iron and unprotected steel pipe. Larger sample sizes help to ensure statistical accuracy, so there is an ongoing need to continue to expand the volume of data. Now, the GTI team is looking to develop a new methodology for implementing revised EFs.

“In addition to updating the existing EFs, we’ll be working to launch a new approach that will enable operators to create utility-specific emission estimates based on their own leak data instead of the national estimates,” said Wiley. “Operators would use the utility’s leak database to more precisely define their emissions profiles. It’s a completely different way of looking at the issue versus the existing ‘miles of pipe’ approach.”

GTI’s focus is on developing a methodology based on the actual number of leaks in a system versus total miles of pipeline. Until now, methane emissions have been quantified by multiplying the EF (for leaks by pipe type) by a “national activity factor” – or a national average of leaks per mile for the given pipe type, an approach similar to that used in the 1996 EPA/GRI study.

“Using total miles is a simpler approach for calculating emissions on a national basis, but it does not acknowledge the efforts of utilities that have implemented aggressive leak repair or rehabilitation programs,” said Wiley.

Instead, the current GTI project aims to develop utility-specific activity factors that use actual leak, repair, and duration records to provide an estimate of the utility’s actual number of leaks. “We believe that this new methodology would provide a good measure for baseline and incremental improvement at the utility level.”

National Grid, an energy delivery company serving customers in the Northeast and a leader in the carbon management arena, recognizes the need for new EFs and a new methodology for calculating methane emissions. “With the current method of calculating emissions, we’re getting no credit for leak repair, lining, or joint rehabilitation,” said Bob Wilson, Director, Gas Materials and Standards at National Grid.

National Grid has set a corporate target to reduce GHG emissions that are a direct result of its operations by 80% by 2050. “With new measurement techniques for accurate quantification of methane emissions that result from the current GTI project, we will be able to more accurately target those actions that will drive us toward meeting that goal,” Wilson added.

Moving Forward

In the final phase of the project, the GTI team will focus on implementation of the new EFs and improving estimates for activity data. In the proposed methodology, activity data may be based on miles of pipeline (as used by the EPA) or on annual leaks records for each utility. The team will address implementation of activity data on a per-leak basis, using existing utility leak records.

“Our goal is to help utilities determine the best approach for integrating these new measurement protocols into their current practices and the level of detail needed for estimating their total annual emissions,” said Wiley.

Another goal of the final project phase is to garner regulatory acceptance of the new methane emissions quantification methods for use by utilities in complying with EPA reporting requirements and compliance with other emission regulations. This will include communicating with various stakeholders such as trade organizations and environmental groups.

“Determining practical strategies for incorporating these proposed improvements in the emission estimation calculations by utilities – and attaining regulatory acceptance -is the last step in the process of helping utilities fully benefit from this multi-phased research effort,” said Wiley.

Leading The Way To The Future

The issue of reducing GHG emissions is a major environmental concern for both the country and the natural gas industry. As such, it will require close collaboration among industry partners if the industry is to improve methods for quantification and to develop technologies and processes for detection, prevention, and mitigation of methane emissions.

Among the ways that GTI is working with industry partners is a joint conference on methane emissions that GTI will co-host with the Houston Advanced Research Center (HARC) in September. “We have also engaged with other organizations to develop smart monitoring systems for methane leaks – for both utility and residential applications,” said Wiley. “And we’re working to provide utilities with more real-time information to enhance safety for customers and communities.”

Clearly, there is much more work to be done. “We are not done yet, but we are well on our way to demonstrating the environmental benefits of using natural gas to serve the nation’s energy needs,” said Lacey.

Editor’s Note: GTI’s CH4 Connections Conference will take place September 23-24, 2014 in The Woodlands, TX. For more information visit www.gastechnology.org/ch4.

Comments