July 2018, Vol. 245, No. 7

Features

What a Gas Measurement Technician Needs to Know for Success

By James N. Witte, Staff Engineer, Southwest Research Institute

The position of measurement technician is one of the most important roles in the transmission pipeline operation. The measurement technician is an operator that is assigned the responsibility for the maintenance and operation of several gas metering and regulation stations in a defined geographic region.

Usually, there are several requirements that go along with this responsibility. This article discusses those requirements and the knowledge and skills that a measurement technician must possess to be successful.

Unlike many pipeline jobs, the measurement technician is required to work alone with responsibility for large geographic areas. Success in this role requires the focus and self-motivation to perform quality work and the expertise to maintain and safely operate metering stations.

Because technicians are often the only employees who interact regularly with customers, they often serve as the de facto company representative and must respond promptly and courteously to any concerns. As a result, the quality of a measurement technician’s training, performance and expressions of job satisfaction may influence how customers view the company and directly affect its operational goals, profitability and reputation.

The typical measurement technician is assigned responsibility for 25-35 metering stations in a service area and provided a vehicle with all the tools necessary for the job. The high-mileage associated with the job requires vehicle replacement approximately every three years, but these intervals can be shortened when corporate mergers result in larger geographic areas.

The technician must conduct tests of the meters on a scheduled basis. Often these require notice to a witness from another company in advance of the test. Everything that is done to affect the performance of a gas meter station must be documented and communicated to the main office on a timely basis.

Commercial transactions in the natural gas industry require a monthly accounting close, and the results of the meter tests and verifications must be reported with sufficient time to accommodate closing in order to avoid prior period adjustments (PPA). PPAs require corrections to financial transactions between two or more commercial entities and must be minimized, because these transactions must precisely equate to a pre-scheduled value.

Some company structures will differentiate the technician duties by making some responsible for only regulators and control valves. Also, there may be a separation of duties related to communications because that job may require special communications licensing and qualification.

In addition to maintaining the metering stations, the technician is also responsible for gas quality enforcement. Gas sampling to determine the composition of the gas and the concentrations of contaminants, such as hydrogen sulfide, water vapor, and other objectionable materials, is required to comply with applicable gas transportation tariffs. The technician must not only have knowledge of the gas quality test methods, but must also know the gas quality requirements in the tariff and gas contract.

Analysis and troubleshooting is important in this role, so a successful technician will have multi-disciplinary skills in electronics, mechanical engineering technology, mathematics and basic chemistry, as well as the ability to use computers, read schematics and engineering drawings, and comprehend technical manuals. The technician also is usually required to understand closed-loop control theory and how to tune the control loops for optimum performance.

Work Force Changes

The industry is presently going through a significant amount of knowledge change as technicians with 20-30 years of experience are retiring and being replaced by inexperienced new hires. This poses a challenge for pipeline companies, because problem-solving ability is essential to a measurement technician’s success, and this type of knowledge is typically gained through on-the-job experience.

Sometimes, the job transition to the new hire is done without a full transference of knowledge from the retiring technician. It is clear that results will vary depending on the focus of management to allow transition time for the on-boarding of the new technician and the beginning aptitude of the candidate technician. A suggested allowance for the transition is one year, with a lot of daily interface time with the experienced technician.

In addition to formal training, new measurement technicians must be willing to engage the seasoned technicians and learn from their experience. Of course, no technician will ever know it all, and it is important to learn through individual study and experience. But engaging senior technicians, engineers, software programmers and vendor technical representatives can accelerate applied knowledge.

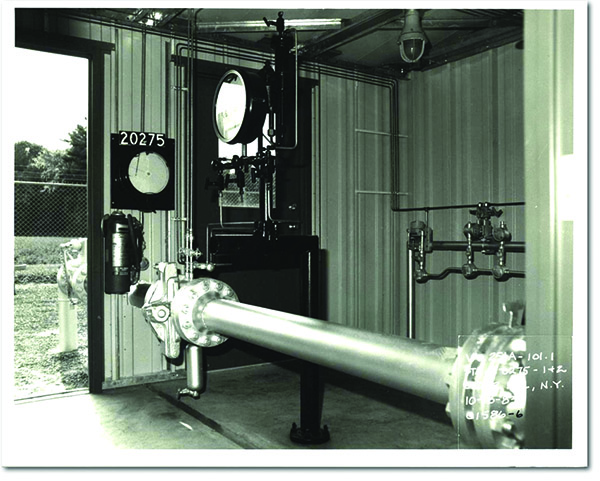

The Equipment

When today’s retirees first entered the workforce, technicians needed a strong knowledge of mechanical and pneumatic devices, and their most commonly used tools might have been an adjustable wrench or a screwdriver for making fine adjustments at metering and regulating stations. Today, the most used tool by a measurement technician is a laptop computer, as current pipeline operations incorporate a higher degree of electronic and computer-based field equipment.

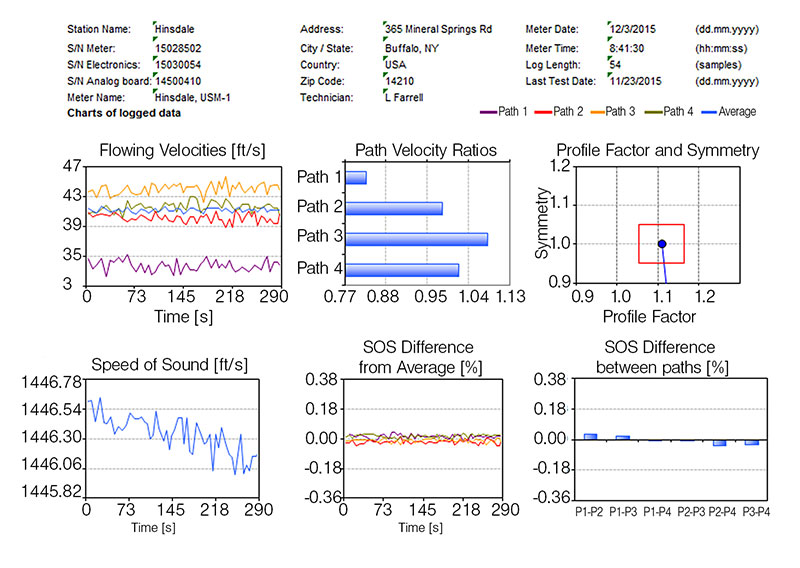

Today’s technician typically relies on corporate support groups, such as Supervisory Control and Data Acquisition (SCADA) and Corporate Measurement. They require custom analytical tools for data analysis, data archival, process trending, and application-specific software. Many of the newer technologies, such as ultrasonic flow meters, provide the opportunity to assess the operational health of the meter and produce custom reports. Interpretation of those reports is a very important skill for the technician to master.

The technology transition has been a constant challenge for the baby boomers. The older technicians might have often been intimidated by microprocessor-based equipment or might not have possessed good computer skills. In this regard, there is a great deal of contrast between the millennials’ willing acceptance of new technologies and that of the outgoing class of technicians.

The technician will have several metering stations with the newer technologies and several with some of the older technologies. This makes the job more challenging, since the technician will have to know how to operate, maintain, and troubleshoot both old and new equipment. The older equipment may require service parts that are no longer available, and it may be challenging for a new technician to determine where a predecessor stored the surplus parts.

Another challenge the new measurement technician must face is to learn and master operator interface software changes and flow computer software changes. Often, the software changes are made by a programmer who does not have to use the software or operate the equipment to which it interfaces.

An oldfashioned solution to this concern is to keep a notebook handy for reference; a best practice is to capture screen shots and assemble a step-by-step description of how to accomplish different tasks. This may speed up the recognition of items that have changed by software version.

Technician Training

In 2010, the Transmission Measurement Committee of the American Gas Association produced a white paper, “Natural Gas Measurement Technician Training and Development Guidelines.” This document attempted to capture the body of knowledge necessary to define a path to competency. It also presented an estimate of the number of hours required for training to occur expressed on a task basis. The information was presented in this manner to allow the path to competency to be customized based on the equipment that a technician would have to operate and maintain.

The basic knowledge level items were described as operate, maintain, or install. The advanced level items were described using the terms troubleshoot and repair. The requirements for complete competency, on the basis of the white paper, projected that some three to five years would be required to reach full competency. Competency was judged as the ability of the technician to execute the various tasks by himself without oversight by a supervisor or trainer.

Many companies are now requiring an associate degree in electrical technology or mechanical technology. Unfortunately, as already noted, the rest of the knowledge requirements for the job are just not taught in colleges. The additional knowledge allows the technician to understand how the meter station operates and to understand when problems might affect measurement accuracy. To a certain degree, the technician develops a deductive intuition when a problem is developing.

Other than task-oriented knowledge, the technician must also know and understand the requirements of all applicable industry metering standards and recommended practices. Many of these documents are named in contracts between the parties and gas transportation tariffs. The technician needs to read and understand these industry metering standards.

Every year, there are several regional schools in the United States that offer technical courses on a variety of gas measurement topics and hands-on training specific to equipment that the technician operates, including: the International School of Hydrocarbon Measurement, American School of Gas Measurement Technology, Appalachian Gas Measurement Short Course, Acadiana Gas Measurement Short Course and Western Gas Measurement Short Course.

The measurement equipment manufacturers also have some very good training classes in which they provide very detailed instructions on equipment operation, troubleshooting and repair.

Communications

The technician must communicate effectively with a number of people who have varying responsibilities and information needs. Internally, these include meter analysts, system balance analysts, corporate measurement engineers, gas control and project managers. It is important that the technician be able to describe through detailed written communication what an observed problem was, what actions were taken and what was the outcome of those actions.

Because measurement is the transactional basis, the technician cannot simply fix a problem without communicating the fact. All of the reporting must be complete and factual. Through effective communication, litigation between the companies may be avoided.

It is important that the technician communicate schedule changes to test witnesses when trouble happens. Otherwise, the witnesses will be needlessly wasting time waiting for a test that may not happen that day. This communication is appreciated by measurement technicians of all companies, and usually because of this, opportunities for learning occur through these verbal communications.

Recordkeeping

The measurement technician is involved with every aspect of recordkeeping as long as he has responsibility for the metering or regulating asset. The technician requests a meter number assignment prior to commissioning any new facility.

Upon station startup, his documentation is used to configure the new meter in the gas measurement system. He must fill out a report for any and all changes to the meter station, meter verifications, and customer-requested special tests.

The technician is also responsible for all of the documentation to support the required U.S. Department of Transportation (DOT) verifications of gas regulators, over-pressure protection devices and gas control system pressure measurement point-to-point readings.

The technician must be certain to be current with the necessary documentation. The current best practice is to use smart electronic forms that prompt the technician for the data input. Regardless of what activities are happening, the technician still has the obligation to complete the DOT inspections as scheduled.

Other Considerations

Industry associates were polled in preparation of this paper and provided quite a few opinions on the topic of what a gas measurement technician needs to know to be successful. Here are a few of the comments that were received:

- The technicians need to take pride in their work.

- The technician must stay current on new metering technologies. This is often done through attendance at any of the several industry gas measurement schools offered across the nation.

- They must read, read, read, and learn as much as they can. “The answer is in the manual.”

- Technicians will never know it all, so ask for training when needed.

- The measurement technician might be unrecognized in the company until trouble happens, but then becomes well-known throughout the company.

- When trouble happens, the technician is always the first to arrive at the meter station and the last to leave.

Conclusions

The gas measurement technician job is arguably the most important job on the pipeline. Through the technician’s efforts, the gas measurement is safe and accurate, system lost-and-unaccounted-for gas is minimal, and transactions occur daily with a high confidence in their integrity.

The knowledge base required for the measurement technician is very broad and challenging. Every day is a new learning opportunity for the technician, and no one is going to know it all.

To be successful, technicians must be honest, possess good analytical skills, learn how to troubleshoot, communicate completely and factually, and have a desire to be continually improving. They also need to seek out opportunities to learn more about the measurement technologies and processes of their company.

Acknowledgements: The author would like to recognize the knowledgeable and insightful contributions of the following individuals toward the preparation of this paper. These contributors are listed as follows: Phil Martin, Kinder Morgan; Joe North, Kinder Morgan; and David Woods, Southwestern Gas. P&GJ

Author:

James N. Witte is a graduate engineer with 30 years of natural gas and petroleum product measurement experience. He has been actively in the advancement of natural gas measurement practices through his leadership roles in the American Gas Association Transmission Measurement Committee and the Pipeline Research Council International Measurement Technical Committee. Witte currently serves as staff engineer for the Southwest Research Institute’s Fluids and Machinery Engineering Department, Mechanical Engineering Division, in San Antonio.

Comments