July 2022, Vol. 249, No. 7

Features

Economic and ESG Cost of Lost and Unaccounted for Gas Errors

By Ernie Hauser, President, C-SMART Analytics

The industry-accepted lost and unaccounted for (LAUF) natural gas storage, processing and transportation averages 0.40% of throughput. LAUF is driven by myriad factors, including pneumatic device integrity and venting, but it is dominated by persistent measurement errors.

Root causes of measurement errors include obstructions, faulty or damaged equipment, and human errors introduced while performing routine maintenance. These events are common but occur randomly, with new events typically amounting to 0.1% of total throughput each month. Indeed, the routine nature of field maintenance only allows for meter inspection and analysis of data monthly or quarterly, a primary reason for the pervasive 0.40% industry average LAUF.

Field staff and back-office measurement teams are simply overwhelmed by the volume and velocity of supervisory control and data acquisition (SCADA) data sets, limiting their ability to analyze meters daily and leading organizations to adopt a more general, and less sensitive, system balancing approach for LAUF, which allows errors to persist for 90 days or more before resolution can be found.

Amid strong natural gas demand and favorable pricing, LAUF has a significant financial impact with the industry losing approximately $3.5 billion per year at today’s natural gas prices. For a service provider that flows 500,000 Mscf per day, underreported volume translates to a $3.6 million annual financial loss.

Over the past two years, the environmental, social, and governance (ESG) conversation has matured. Government policy, Wall Street, private equity and industry leadership are now hyper-focused on Scope 1 greenhouse gas reduction with Scope 2 expected to place an even heavier reporting burden on midstream companies. Companies must now optimize on both financial and ESG cost dimensions. Adding complexity, the International Energy Agency (IEA) asserts that the industry has underestimated methane emissions by 70%.

While most approaches to this problem are centered on new technology to monitor and measure emissions in real time, deployment of these solutions, and the attendant accuracy of the measured results, will take time to develop. In the meantime, to benchmark their performance against ESG goals, the industry must improve their volume flow measurement accuracy and factor out LAUF errors to deepen our understanding of carbon intensity.

In addition to the $3.5 billion annual loss, the industry carries a potentially massive emissions liability at the accepted 0.40% LAUF, when volume flow measurement errors cannot be distinguished from potential emissions. This underscores the need to eliminate LAUF errors to determine an organization’s true carbon intensity baseline liability if midstream is expected to demonstrate emissions reduction. Unlike the future deployments of new technologies for measurement of emissions on the horizon, the capability to significantly lower LAUF is already proven and can be deployed immediately.

Management by Exception

Digital transformation and the Internet of Things (IoT) have brought rapid change to natural gas measurement with the introduction of ultrasonic meters (USMs), flow computers and connected gas chromatographs, exponentially increasing the availability of diagnostics data.

Despite these digital advances, the technology and data are largely underutilized. Manual data curation and analysis impede timely diagnosis of gas measurement errors at a time when teams have the unprecedented opportunity to prioritize meter troubleshooting based on real-time and continuous monitoring of remote measurement stations.

For measurement assurance, the status quo of monitoring and responding to equipment problems through rigid, scheduled maintenance exposes organizations to higher operating costs (e.g., large staffs or third-party technicians and consultants), financial risk from under- or overreported volumes, operational inefficiencies and carbon intensity uncertainty.

The cloud, edge computing and augmented intelligence are bringing much-needed automation and analytics to gas measurement, enabling teams to monitor and manage equipment by exception and dispatch field staff to the highest priority errors at metering stations.

As a result, Augmented Intelligence and IoT Technology (AIIT) have successfully shifted the paradigm from scheduled maintenance and manual analysis to real-time optimization of gas measurement assurance, enabling errors to be rapidly diagnosed and resolved in a matter of hours compared to scheduled inspections that take weeks or months and, even then, may not catch or correctly diagnose LAUF errors.

AIIT empowers organizations to proactively manage meter maintenance by exception, reduce unnecessary scheduling of limited field resources and address the financial and ESG costs associated with LAUF.

Early adopters of AIIT have leveraged C-SMART Analytics, a pioneer in gas measurement, analytics and diagnostics. The following sections present case studies that demonstrate and quantify the financial and ESG impact of LAUF and the role of AIIT and C-SMART Analytics in addressing the industry’s LAUF challenges.

Case Study 1

Leveraging the C-SMART Analytics AIIT monitoring solution, a midstream company operates multiple custody transfer measurement stations in Texas. The company switched from scheduled inspection of its metering stations every month to a management by exception approach to maintenance.

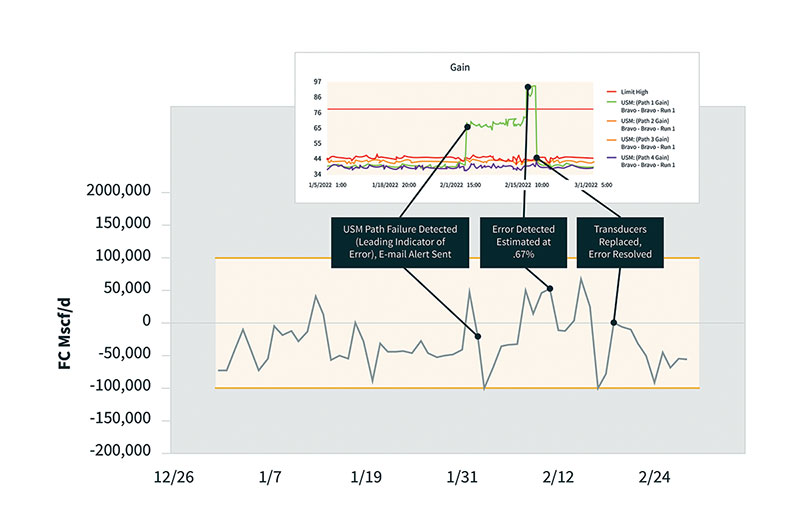

C-SMART Analytics automatically detected a potential error with a USM’s flow measurement. USMs use an array of ultrasonic transducers to measure the gas velocity in specific sections of the pipe.

These individual measurements are integrated into an average velocity measurement and, in turn, a flow rate. C-SMART detected that one of the measurements was intermittently in error, enabling the midstream company to rapidly dispatch field staff, who replaced the specific transducers in question. During the failure, the meter over-registered by 5,700 Mscf/d.

Gone undetected, the error would have resulted in overpayments of $22,800 per day at $4/Mscf, requiring extensive prior period adjustments if and when finally addressed. Importantly, the extent of such LAUF errors creates carbon intensity uncertainty by overreporting the company’s potential ESG liability.

Case Study 2

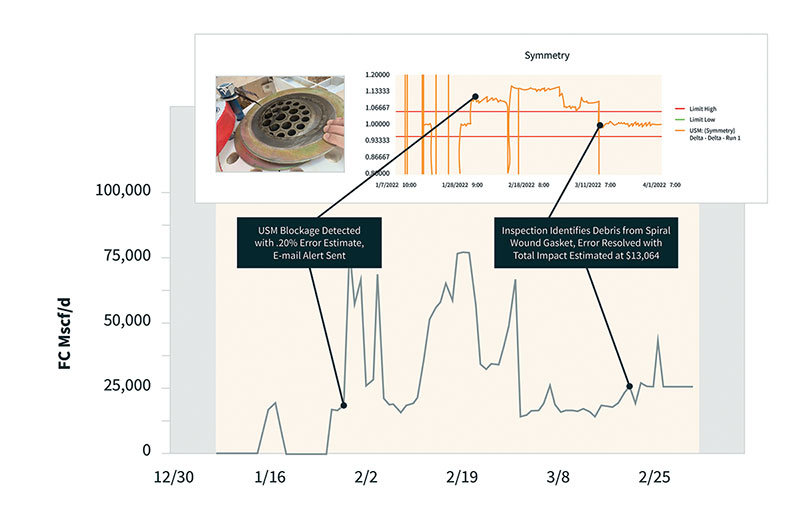

A pipeline operator in Oklahoma encountered a blocked USM when the velocity of gas flowing through it increased, splitting off part of a spiral-wound gasket. The debris became lodged against the USM flow conditioner impeding the meter’s ability to accurately measure the gas stream and causing volumes to be underreported.

Leveraging C-SMART Analytics and AIIT, the USM blockage was automatically detected, and a real-time alert was sent to the operator’s measurement team recommending an internal inspection of the meter tube. The AIIT solution estimated the LAUF error at 0.20% per day, resulting in a loss of $13,064 at $4/Mscf. This LAUF error could also overreport the operator’s potential emissions liability by 2,654 Mscf.

Due to winter operational issues, the error lasted for six weeks before maintenance could be performed. However, the root cause of the LAUF error and duration were automatically captured by C-SMART Analytics’ AIIT measurement diagnostics, enabling gas volumes to be reconciled and providing the operator with valuable insights to address similar issues in the future and ensure the event is resolved.

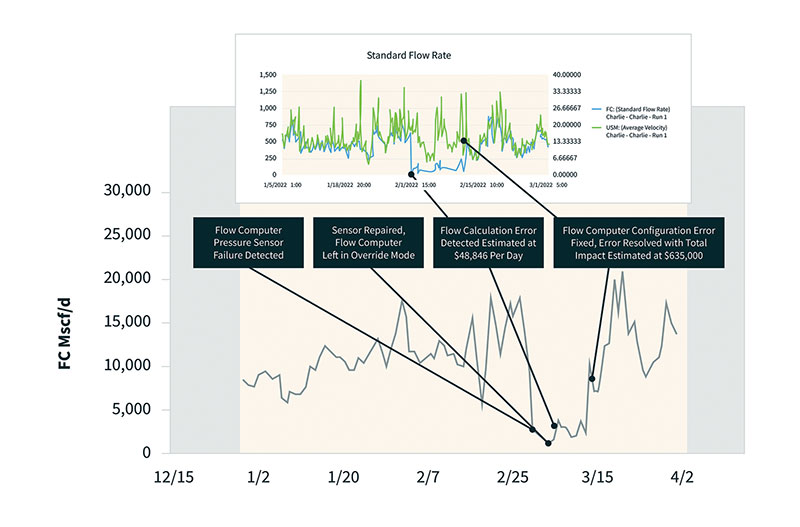

Case Study 3

The following illustrates how manual meter inspections can ironically lead to LAUF errors and the value of continuous, automated monitoring of metering stations. With C-SMART Analytics providing real-time diagnostics for its processing facility, a Texas-based operator was immediately alerted when a flow computer pressure sensor failed on a USM. The company’s field operations team replaced the pressure sensor within 24 hours of the failure, but in the process of repairing the meter the technician accidentally left the flow computer’s pressure measurement in override mode at a constant psig.

The AIIT monitoring system detected a flow measurement calculation error following the pressure sensor repair, prompting the service provider to return to the meter location and correct the flow computer configuration error. Gone undetected, the financial impact from the LAUF error is estimated at $48,846 per day at $4 natural gas pricing while overreporting potential emissions and ESG liability by 9,769 Mscf per day.

LAUF Correction

Net-zero policies and global alignment on greenhouse gas reduction are leading investors and stakeholders up and down the value chain to a clear consensus on emissions reduction. LAUF measurement errors are standing in the way of truly understanding the industry’s carbon intensity and actual ESG liability at a time when individual organizations will be expected to provide reliable emissions reporting.

The arrival of AIIT is well timed to help factor out measurement uncertainty and provide ESG stakeholders with the most reliable carbon intensity data as Scope 1 reduction focus accelerates.

Additional ESG benefits of AIIT include:

- Enabling organizations to stop reacting to ESG with a proactive layer of verification and validation

- Preventing “phantom emissions”/false positives that are actually measurement errors

- Identifying LAUF errors in a timely manner and eliminating unnecessary employee hours and travel, thereby reducing vehicle emissions and safety issues

- Supporting auditing of the gas stream with defensible data for auditing of fugitive emissions

- Establishing credible baseline and supporting Responsibly Sourced Gas certification

Conclusion

AIIT has shifted the paradigm of scheduled meter maintenance and manual analysis to maintenance by exception, eliminating the need to send personnel to metering facilities regularly that are operating correctly.

At the same time meter analytics and diagnostics harness the full power of today’s connected measurement equipment to deliver insights in real time that prevent costly errors. AIIT is assisting midstream companies in eliminating LAUF errors that uplift corporate margins through quantifiable measurement improvement, acceleration of meter repair and productivity gains as staff switch from routine inspection routes to prioritized maintenance activities.

Beyond mitigating financial risks, AIIT enables organizations to accurately determine their carbon intensity baseline as the industry focuses on improving ESG. Given the importance of natural gas to the new energy mix, gas measurement accuracy and confidence in data are even more critical moving into the future.

Author: Ernie Hauser Ernie Hauser, president of C-SMART Analytics, has more than 30 years of experience in the design, sales and manufacture of ultrasonic flowmeters. He has been a significant contributor to innovations in measurement, including contributions to numerous USM patents, the introduction of the 8-path meter to oil and gas applications, and the creation of the Measurement Uncertainty Recapture (MUR) Uprate market for nuclear power plants worldwide.

Comments