June 2023, Vol. 250, No. 6

Features

Software Adds Efficiency for Companies Transporting, Storing Hydrogen

By Rohan Awasthi and Martha Rendon, Emerson

(P&GJ) — Decarbonization is a critical challenge facing the world today, and the expansion of renewable energy sources is a key component of addressing this challenge. In the face of changing corporate and public goals with regards to the low-carbon energy transition and changing energy landscape, many companies are looking for opportunities to support more sustainable forms of energy.

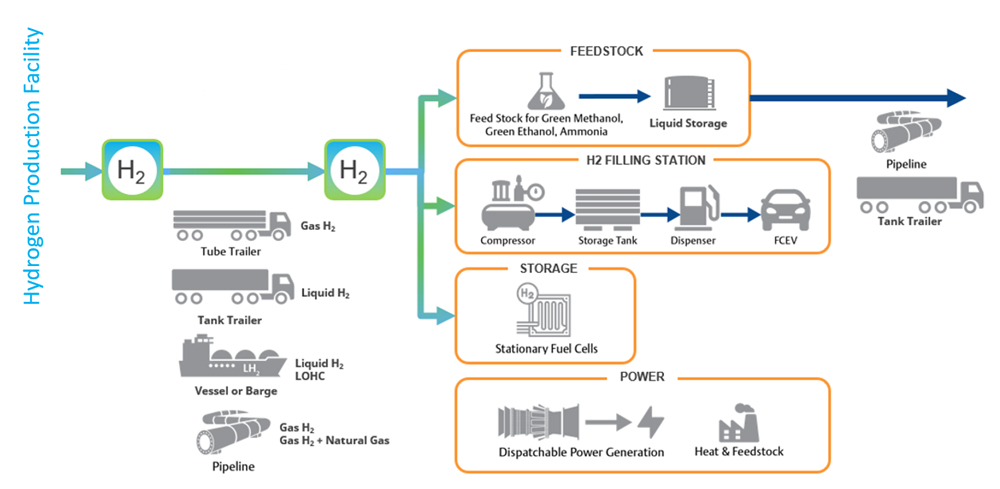

One of the more common ways this shift has manifested is that many companies have added hydrogen to their portfolios, leveraging the equipment they have in place to transport and store a more sustainable product.

However, as companies evolve operations to support more sustainable solutions like hydrogen, they quickly introduce more complexity across the value chain (Figure 1).

While gaseous hydrogen can be transported through existing pipelines used for natural gas transportation, it typically requires the development of large-volume transportation and storage methods that can support higher energy density. Storage of hydrogen as a liquid also requires cryogenic temperatures, another factor to consider.

Moreover, hydrogen is corrosive and tends to degrade pipelines, making it important to closely monitor for leaks and wear on the pipeline network.

The monitoring and maintenance necessary to manage the hydrogen value chain efficiently and cost-effectively from operations to commercial management requires modern technologies to reduce risk.

Software for leak detection, optimization, forecasting, scheduling, risk modeling, and order-to-cash that offer simulation, machine learning, and more are all key to an optimized value chain. However, to drive the most value, these systems should be part of a boundless automation vision, using technology across every domain to integrate operations and deliver contextualized, democratized data.

Such a foundation is difficult to accomplish with a wide array of disparate solutions linked by custom engineering, as this leads to high risk and costs. In addition, existing software solutions that are decades old are out-of-date and do not reflect current industry standards.

This issue is particularly problematic in hydrogen, which is an evolving economy with inevitable changes. Personnel will need to take the time to manually update the system wherever possible – a solution that requires staff with both free time and expertise.

A better solution is to move to a more cohesive software ecosystem where supervisory control and data acquisition (SCADA) systems are seamlessly integrated with applications designed to meet energy industry requirements.

By selecting flexible yet fit-for-purpose solutions, companies can more easily achieve greater long-term efficiency while requiring fewer changes operationally as hydrogen and other new products are introduced into their operations.

Automating Scheduling

Managing nominations efficiently is critical to a successful hydrogen value chain. Pipeline operators must be able to effectively plan and schedule nominations to ensure that contracts are met and customers are satisfied. However, inefficient management techniques make it difficult to obtain and analyze the data necessary to manage nominations.

A better approach is to use a modern capacity management system with the capability to model nomination requests and changes. Automated nomination and scheduling systems enable long-term capacity planning by utilizing real-time data to alert schedulers of outages and pullbacks.

Implementing this type of automated solution requires a significant amount of data to be properly delivered to the capacity management system. Therefore, selecting software that connects seamlessly to any SCADA system is needed to ensure proper data from all required systems is delivered at the right time.

An integrated approach allows the nomination software to generate a better model, that in turn enables more accurate scheduling. This level of automation leads directly to increased profitability by lowering total cost of operations, reducing emissions and energy consumption, and allowing for easier, more cost-effective maintenance without unplanned disruptions.

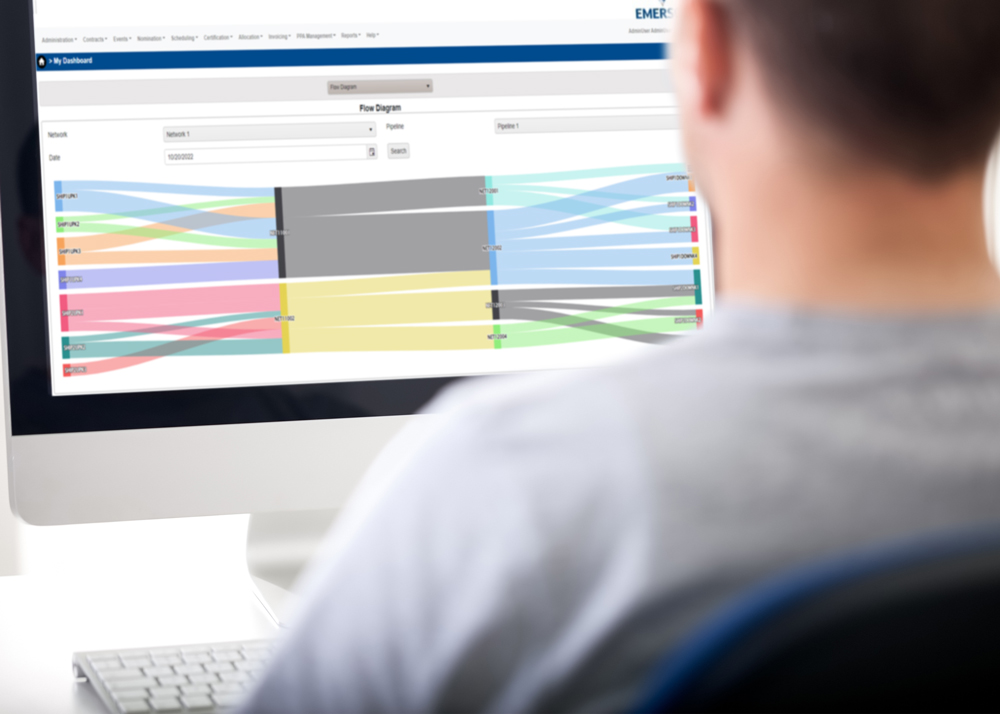

By enhancing the nomination process, pipeline companies also realize greater shipper satisfaction because pipeline operators can now easily communicate and share information with all their shippers and third parties, including producers, processors, transporters, and end users. This type of modern software is simple to set up and offers comprehensive web-enabled functionality to make key information available quickly and easily to internal and external users (Figure 2).

Terminal Operations

Liquified hydrogen poses challenges for terminal operators due to its hyper-cold requirements. As this new energy form begins to enter the landscape, operators with optimized operations will be better equipped to continuously satisfy the needs of a wider variety of customers.

With expanding global energy demands, there will be an increased urgency to meet these needs without delay, while managing the complexity of large, multi-modal terminal facilities.

To better manage individual customer needs, those same operators are simultaneously trying to reduce truck turnaround time, increase terminal throughput, maximize efficiency of loading bays, and manage the needs of carriers and drivers. And through it all, the company is likely also trying to reduce operating costs and increase revenue, while keeping safety incidents to an absolute minimum – a complex proposition at best.

Much of the data that is needed to manage all aspects of the operation is tied up in complex spreadsheets built long ago by a small group of experienced users. But today’s terminal operations are far more complicated than the operations of decades ago, and those spreadsheets are unwieldly, if they are still usable at all. Every entry on a spreadsheet is subject to error or inaccuracy, and because these entries are often connected by complex macros, one small error can cascade across a project and become a massive headache for operators down the line.

To avoid these problems and increase efficiency and revenue, forward-thinking terminals are using software to optimize and automate the loading process. Using this type of solution, information about terminal operations is centralized for easy visibility, yielding more intelligent planning and decision making.

Built-in tools are available and usable out-of-the-box to increase asset utilization and maximization of high-value tasks for onsite resources, while simultaneously increasing terminal throughput, with safe and accurate loading for every movement.

As with loading operations, scheduling within a terminal can be significantly enhanced with the right technology. Best-in-class terminal scheduling software uses digital twin simulation – a detailed replica of the facility with digital representations of critical physical elements – to help users automatically generate an actionable schedule to manage lines, tanks, valves, pumps, interconnections, and more.

Companies diversifying operations to move newer products like hydrogen will likely need to satisfy a larger pool of customers, each expecting efficiency, insights, and optimization. Software that centralizes data will allow terminal operators to meet these challenges by enhancing all aspects of product movement.

Order-to-Cash

The order-to-cash process for both pipeline and terminal operators is driven by regulations and laws. Because noncompliance can lead to penalties or contract disputes, it is essential that data can move efficiently and seamlessly from the company’s SCADA or terminal automation system (TAS) to its commercial management solutions.

In the most complicated scenarios, pipeline and terminal operators manage this data interaction via complex spreadsheets. Unsurprisingly, this leads to frequent data loss, or incorrect entries and tracking, resulting in inaccuracies.

Moreover, today’s operations are typically widespread and working with a fraction of the personnel they had only five or ten years ago. And the personnel they do have often lack tribal knowledge, making it more challenging and time consuming to use complex spreadsheets developed by their predecessors.

This type of system is further complicated when one of the macros in those spreadsheets breaks, and the person who originally created it is no longer with the company. Reverse-engineering manual solutions means spending significant time and effort on low-value tasks.

Companies leveraging modern software are streamlining the order-to-cash process and closing their books faster at month end. Advanced commercial management software is backed up by a full support system which can provide updated software to reflect the latest compliance standards to ensure contracts are properly managed, information is shared correctly, and contract requirements are met on time and to specification.

The most advanced solutions connect seamlessly to any SCADA system or TAS, as well as to an enterprise resource planning system. Users can easily bridge the gap between operational and commercial requirements to cohesively manage the entire process. By using order-to-cash software, companies can deliver improved customer satisfaction with expedited billing, approved accounting accuracy, and easier invoice management (Figure 3)

System Benefits

While many software solutions exist to solve the potential problems along the hydrogen value chain, the most successful organizations will focus on holistic solutions that interconnect and interoperate seamlessly. Not only do these software solutions need to easily communicate with the SCADA system or TAS, but they must also provide efficient and intuitive access to business systems in the cloud and on premises, such as enterprise resource planning software.

Those connections need to be reliable and secure, which is significantly easier with a single, modern, best-in-class software ecosystem that is seamlessly integrated by design. Such a solution eliminates the need for complex homebrew interfaces between systems that make it hard to maintain and update the entire system.

Moreover, because pipeline and terminal operations are no longer under the radar of cybersecurity bad actors, companies must implement strong cybersecurity solutions across their operations. Modern, integrated solutions improve cybersecurity across the enterprise – an essential consideration now that systems are connected to the cloud.

Today’s best solutions for managing the hydrogen value chain are built from the ground up with cybersecurity in mind. They offer system and organization controls (SOC) 1 and SOC 2 compliance – as well as Industrial Society of Automation ISASecure certification – to help ensure that all connections among management, enterprise, and SCADA systems or TAS are as secure as possible.

Preparing for Tomorrow

Today’s hydrogen operations are only beginning. As technologies evolve and demand increases, so too will the complexity of operations across the value chain. By moving to a holistic, integrated, cohesive solution with fit-for-purpose applications integrating seamlessly into SCADA, TAS and business systems, companies are improving efficiency, security, and performance, while simultaneously offsetting new challenges, such as staffing limitations and cybersecurity risks.

Today’s best-in-class solutions offer improvements out of the box, helping companies prepare their operations with modern technologies offering machine learning and artificial intelligence. These types of solutions drive the forecasting and performance improvements necessary to better compete in an evolving energy industry.

Authors: Rohan Awasthi is product manager of Emerson’s Synthesis Software and has deep expertise in commercial management of oil and gas pipelines and terminals. He brings 15 years of experience to his current role, and his responsibilities include product feature design, along with product roadmaps and managing product release lifecycles. Awasthi holds a master’s degree in chemical engineering from the Indian Institute of Technology in Kanpur and an MBA degree from Rice University.

Martha Rendon is senior product manager for Emerson’s Gas Management Solutions portfolio. She has over 20 years of experience of which 15 years have been in the energy sector, with a focus on globally deployed software projects, systems design, and product roadmap management. Rendon holds a bachelor of systems engineering computer science degree, and a master of organizational control business administration and management degree, both from EAFIT University in Medellín, Colombia.

Comments