November 2023, Vol. 250, No. 11

Features

Guyana Moving Toward New Offshore Gas Pipeline in Liza Offshore Fields

By Mauro Nogarin, P&GJ Latin America Correspondent

(P&GJ) — With the Gas To Energy project, the government of Guyana will — for the first time — produce energy using the associated natural gas produced in the Liza offshore fields of the Stabroek Block.

The company Esso Exploration and Production Guyana Limited (EEPGL) — at the request of the government — has been commissioned to design this project that consists of the construction and operation of a gas pipeline, connecting the FPSO vessels Liza Phase 1 and Liza Phase 2 to the LNG and NGL processing plant located on the mainland.

The pipeline will transport up to 50 MMcfgd to the plant location, where it will be depressurized, dehydrated, separated as propane, butane and pentanes plus and treated, according to the technical specifications established by Guyana Ministry of Energy.

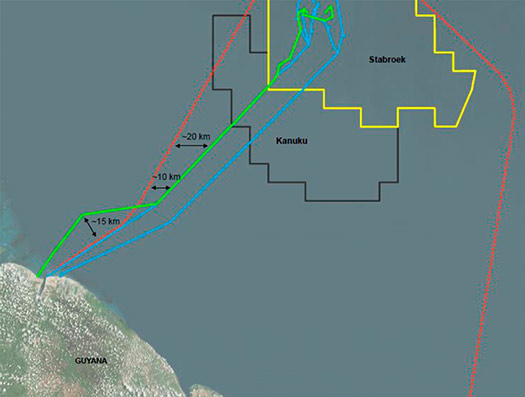

The offshore pipeline is 137 miles (220 km) long, running from new subsea connections at the Destiny and Unity FPSOs to an onshore location, west of the mouth of the Demerara River.

The onshore pipeline extends another 16 miles (25 km), from the onshore connection point to the NGL plant. The NGL plant and associated infrastructure is located 14 miles (23 km) upstream from the mouth of the Demerara River, on its western bank.

The project, as presented by the consortium to the Environmental Protection Agency (EPA), showed the gas pipeline to be 12.75 inches in diameter, reaching from the existing offshore gas production facilities to the Guyana coast and on to the plant processing the LNG.

The section, as indicated by the government of Guyana, has an ROW of about (200 meters) of the ROW for the established offshore route, while the nominal area of temporary work space required during the construction of the onshore gas pipeline will be about 75 feet (23 meters) wide, which will result in a temporary construction site of about 148 acres (60 hectares).

The offshore pipeline’s contract for management, engineering and installation of the gas pipeline has been awarded to Subsea 7 and Van Oord, and it will be carried out at a depth of (1,450 meters).

The pipeline will be welded offshore, using an installation vessel and then laid on the seabed from the offshore connection point, with the FPSOs up to the 65-foot (20-meter) bathymetric contour, where the “nearshore area” begins. In the nearshore area, a trench will be excavated, and the pipeline will be laid in the trench, which will then be backfilled. In the last few miles near shore, the pipeline may be installed using horizontal directional drilling (HDD).

During pre-commissioning, the pipeline will be flooded, cleaned, gauged, hydrostatically tested, dewatered. Inert gas will be introduced to produce non-ignitable atmosphere. During commissioning, the natural gas stream will be introduced into the pipeline system, in preparation for start-up activities.

The pipeline will be operated with the rest of the facilities, in accordance with the developed operating procedures, including maintenance and inspection pigging procedures.

The mainland connection point will be located west of the Demerara River — that is, 2.5 miles (4 km) northwest of the mouth of the same river. From the landing stage on land, the pipeline will be installed underground to the site, using a combination of conventional open pit construction techniques and using the HDD method, especially for road and river junctions.

The route on the mainland, whose contract has been assigned to the Italian company Sicim, is 16.7 miles (27 km) long, and it allows for the predominant use of open-air construction, by taking advantage of the easements available under state control throughout the channels and associated paths.

To allow optimization of pipeline construction work, the temporary ROW and final ROW will be determined after optimization. The width of the construction ROW is 75 feet (23 meters), while the minimum coverage depth will be 4 feet (1.22 meters).

For the sections that will be built with open cut methods, a trench will be excavated in segments along the ROW. Based on the height of the water table, the construction activities in the trench will implement drainage with hydraulic pumps. The pipe segments will be threaded and welded along the excavated trench and then lowered into the trench for final welding.

The HDD sections will be constructed though directional drilling, from an inlet to an outlet point. Following this, the pipe will be welded from one side of the borehole and pulled from the other, using a pulling head and winch.

Upon completion of the hydraulic test, the trench will be back-filled with the excavated material to the extent possible. Finally, the previous commissioning of the offshore and onshore sections will be carried out at the same time.

The project is expected to come online in the second half of 2024.

Comments