May 2024, Vol. 251, No. 5

Features

Case Study: Risk Management for Valve Rupture Mitigation in Pipeline Operations

Special to Pipeline & Gas Journal

Federal pipeline regulations in the United States (49 CFR 192.935(c)) require that operators perform a risk analysis to determine where the use of rupture mitigation valves (RMV), such as remote-controlled valves and automatic shut-off valves may be efficient to add protection to high-consequence areas.

In addition, regulations (49 CFR 192.935(f)) require that these risk analyses are certified by a senior executive of the pipeline operator on an annual basis.

To support meeting this regulatory requirement, as well as to enhance existing risk management, in 2023, a US transmission pipeline operator retained Dynamic Risk to perform an independent RMV risk analysis. Effectively, an RMV risk analysis must evaluate the potential risk reduction from a rapid valve closure enabled through the installation and operation of RMV technology.

Since the rapid valve closure is a mitigative measure that would occur after a pipeline rupture has occurred, the focus of the risk analysis is on evaluating the reduction in consequences of failure.

Additionally, in the context of natural gas pipelines, the primary benefit of rapid valve closure is the potential to minimize damage to buildings by allowing faster, safer access for emergency responders, particularly to extinguish secondary fires.

While the pipeline operator’s existing pipeline risk assessment model utilized for integrity management evaluated likelihood and consequences of failure, a targeted risk analysis was sought to proactively analyze the specific mitigative measure of a rapid valve closure in conjunction with fire-fighting efforts to potentially reduce building damage following a hypothetical ignited pipeline rupture.

Solution

Evaluating potential damage reduction of rapid valve closure along with fire-fighter response is a complex analysis that encompasses the consideration of several variables, including:

- Time it takes to close valves to isolate pipeline segment

- Location of pipeline rupture

- Properties of the pipeline at rupture location

- Transient gas release mass flow

- Thermal radiation based on transient gas release

- Proximity of structures to the pipeline

- Area where buildings could be potentially affected by thermal radiation

- Type and size of structures potentially impacted by thermal radiation

- Area where fire-fighters could safely access buildings after a rupture (Fire-Fighting Circle)

- Response time for building fire-fighting

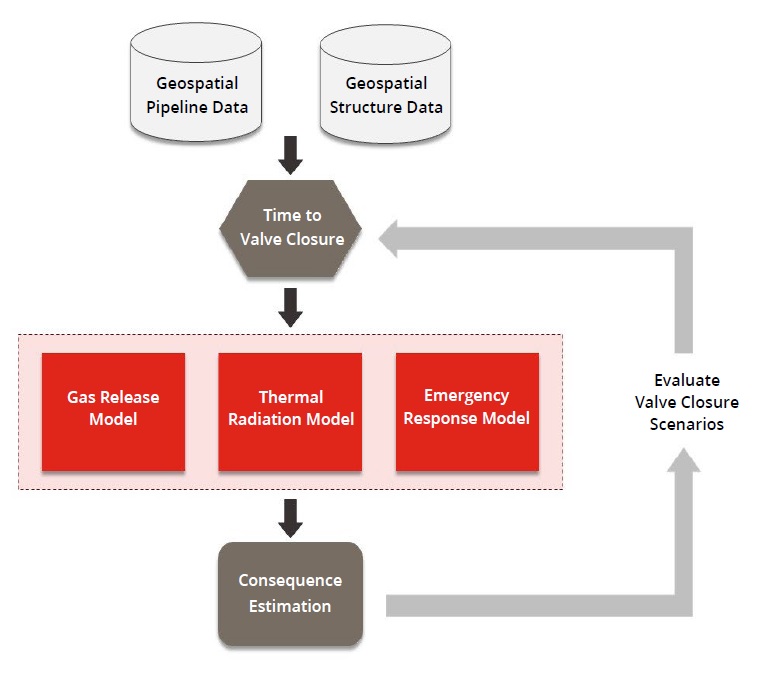

Dynamic Risk developed a risk-based solution to consider these variables and simulate a hypothetical rupture at multiple points along the pipeline system to determine site locations where rapid valve closure, combined with fire-fighting efforts, could potentially reduce building damage.

As a first step, the pipeline operator provided engineering and software applications contractor Dynamic Risk with geospatial data of their pipeline system as well as any buildings in proximity to the pipeline.

Then, using geospatial analytics technology, the pipeline and buildings data was integrated within a gas release model, thermal radiation model and emergency response model to perform consequence estimation at dynamically segmented points along the pipelines, including evaluating the following:

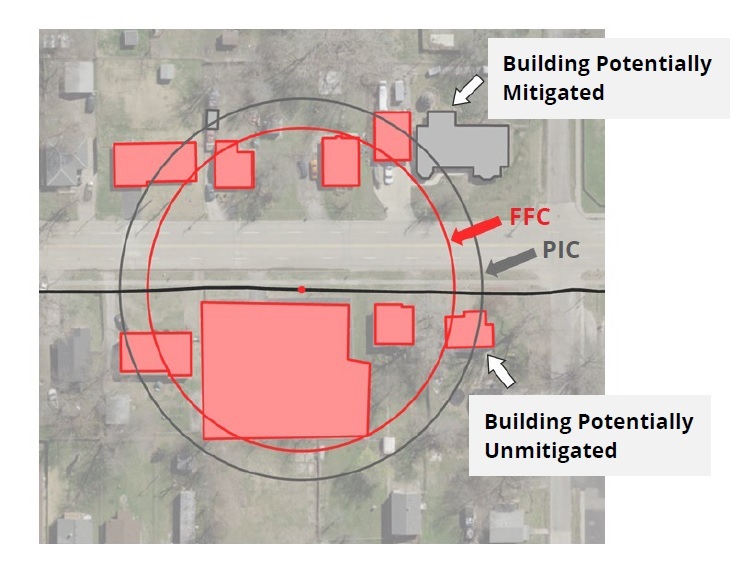

- Radius of potential impact circle (PIC) was determined based on the formula in CFR 192.903.

- Radius of the fire-fighting circle (FFC) was estimated based on assumptions for the time to close valves, gas release model, thermal radiation model, and the emergency response model.

- Buildings within the PIC and FFC were identified.

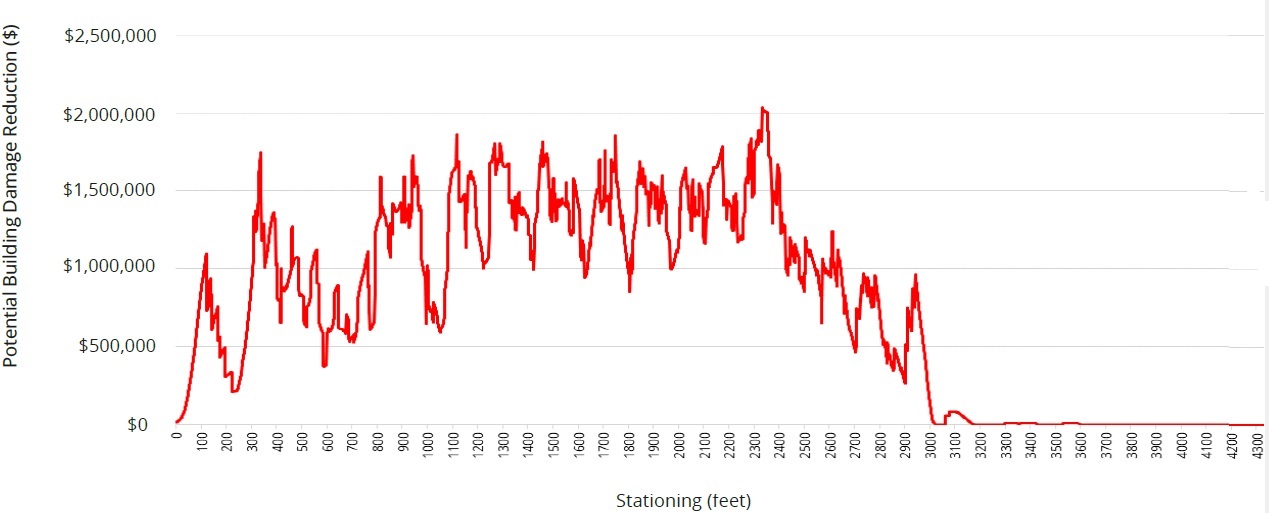

Buildings that were determined to be within the PIC but not within the FFC were considered to be potentially mitigated by fire-fighting activities. The value of the potential building damage reduction was based on several factors, including the size and type of building. Once the potential building damage reduction was estimated it could be plotted along each pipeline segment (Figure 3).

Subsequently, for each of the approximately 300 pipeline segments assessed in the pipeline operator’s network, a comparison was made between the maximum potential reduction in building damage for each segment and the projected cost of installing RMV technology in that segment.

This comparison aimed to evaluate whether implementing RMV was an efficient mitigation strategy, specifically determining if the potential reduction in building damage outweighed the costs associated with application of the mitigation measure.

Project Outcome

The RMV risk analysis was completed over a period of several weeks after receiving the geospatial data and provided potential building damage reduction estimates along nearly 300 pipeline segments that were in a high-consequence areas (HCA).

Considering the estimated installation costs of RMV, a comprehensive assessment was performed to determine where RMV may be an efficient measure to add protection to an HCA. This provided a screening level risk-based prioritization for the pipeline segments in the scope of the project.

Overall, the results of the analysis showed that for most of the pipeline segments, the estimated cost of installing RMV exceeded the estimated potential building damage reduction cost, and thus may not be an efficient use of resources to manage risk.

For those few pipeline segments where the potential building damage reduction was estimated to exceed the cost to install RMV, they were prioritized for additional detailed analysis.

The RMV efficiency results provided reasonably addressed the requirements of CFR 192.935(c). The results can inform and support the pipeline operator’s decision-making about potential additional measures that could be taken to mitigate the consequences of a potential pipeline rupture, including the option of installing RMV.

In addition, there was information provided from the analysis that was useful in support of the pipeline operator’s broader transmission integrity management program.

“A key to the project’s success was close collaboration with the pipeline operator’s team to iteratively make adjustments as the solution was applied to actual geospatial data”, said Curtis Parker, Dynamic Risk’s Technical Lead on the project. “There were many variables to consider that had to be aligned with the appropriate attributes in the geospatial database to ensure accurate results, and the cooperation between teams made this possible in a timely manner.”

Benefits

- Demonstrated adherence to US federal regulations by conducting a thorough RMV risk analysis as mandated, ensuring that the process meets or exceeds the established standards.

- Provided a proactive approach to risk mitigation, and the protection of HCAs.

- Highlighted pipeline segments where installation of RMV exhibited a potential to be an effective mitigative measure, indicating areas where investment in RMV could yield significant safety improvements.

- Established a framework for prioritizing pipeline segments requiring in-depth consequence analysis, thereby enabling the allocation of resources towards areas with the highest potential for risk reduction.

- Increased risk management effectiveness by ensuring that the pipeline operator’s resources are invested in the highest-value risk management projects and activities.

- Identified opportunities for enhancing emergency response planning and preparedness.

- Augmented the pipeline operator’s existing risk management program with a detailed characterization of potential consequences that enables targeted prevention and mitigation measures.

- Integrated the latest technological advancements in RMV systems, ensuring that the pipeline operator’s infrastructure benefits from the most efficient and reliable safety mechanisms currently available.

- Established a system for regularly updating risk analysis models to incorporate new data, technological improvements, and changes in regulatory standards, ensuring that the risk management strategy remains current and effective.

Comments