May 2025, Vol. 252, No. 5

Features

Ensuring Natural Gas Purity: How Utilities Detect and Remove Pipeline Pollutants

By Alan Garza, Marketing Manager, Endress+Hauser

(P&GJ) — Natural gas utility pipelines are vital for providing energy to homes and businesses around the continental U.S. This network is dependent on gas purity, created through high-quality feedstock and gas processing systems, to maintain operational integrity, service reliability, environmental protection and safety.

The presence of contaminants in distribution pipelines can cause corrosion, equipment damage, environmental pollution and even rare catastrophic events that harm human life. As a result, robust gas quality processing, monitoring and maintenance is essential to ensure compliance with regulatory standards and safeguard gas processing assets, infrastructure and people.

This article delves into key challenges of preserving quality in our pipelines and covers various gas analysis technologies that address these concerns. It then explores these innovations in specific utilities applications — including natural gas production, processing, transmission, storage and distribution — highlighting the critical role of accurate and reliable measurement.

Maintaining Quality

From deep underground where natural gas is harvested to end-user consumption, there are numerous opportunities for contaminants to enter a natural gas stream. Hydrogen sulfide (H2S) — a highly toxic and corrosive gas, and one of the primary impurities found in areas where natural gas is extracted — is naturally present in many natural gas basins. Removal of this molecule requires meticulous monitoring and processing to meet appropriate regulatory and safety standards.

In addition to H2S, other contaminants — such as water vapor (H2O), carbon dioxide (CO2), oxygen (O2) and other various hydrocarbons — can also detract from gas quality and cause operational deficiencies. For example, H2O combined with H2S can form highly corrosive acid that damages pipelines and equipment; CO2 can reduce the heating value of natural gas, causing hydrate buildup that blocks pipelines and O2 ingress poses combustion risks and can accelerate corrosion.

While methods exist to measure and scrub these impurities, the intermittent nature of certain gas streams — with fluctuating compositions and contaminants like glycol, methanol, amines, and other sulfurous compounds — complicates reliable gas analysis. As a result, traditional measurement methods often struggle to accurately identify complex permutations, which compromises process control and safety.

Analysis Limitations

Historically, utilities have used lead acetate tape to detect H2S by placing a paper tape coated with lead acetate directly into the gas stream. When H2S is present, it causes a visible discoloration on the tape, which indicates the relative concentration of the contaminant. However, this technique is labor-intensive, requires frequent tape replacement and provides only limited accuracy and sensitivity, making it unsuitable for continuous monitoring and precise measurement.

Another conventional measurement method uses broadband UV light, typically originating from a deuterium lamp. The emitted light covers the absorption bands of many target gases in a natural gas sample, directing the light through a spinning filter wheel with a series of narrow bandpass membranes.

Each of these membranes allow specific wavelengths of light to pass through, corresponding to the absorption bands of particular target gas contaminants. Some of the spectrum is absorbed by the sample, and the wavelengths captured at a detector on the other end, typically a photomultiplier tube, reveal the sample’s composition and concentration.

While this latter method provides improved accuracy, compared to lead acetate tape measurement, it is susceptible to interferences from sulfuric and aromatic compounds. Additionally, the light source degrades over time, causing measurement drift that requires calibration almost daily. To combat interferences, chromatographic columns are often employed, which separate H2S from other species. However, this adds complexity to the procedure and increases the time required for analysis.

Advanced Solutions

As a way to address these and other issues, tunable diode laser absorption spectroscopy (TDLAS) emerged as a leading technology for gas analysis applications throughout many industries. TDLAS analyzers employ a laser beam adjusted and tuned to numerous wavelengths, each of which is absorbed by different gas molecules, Fig. 1.

The amount of light absorbed at each wavelength is directly proportional to the concentration of each component being measured, as described by the Beer-Lambert law, providing precise measurements over a multitude of potential contaminants in natural gas streams.

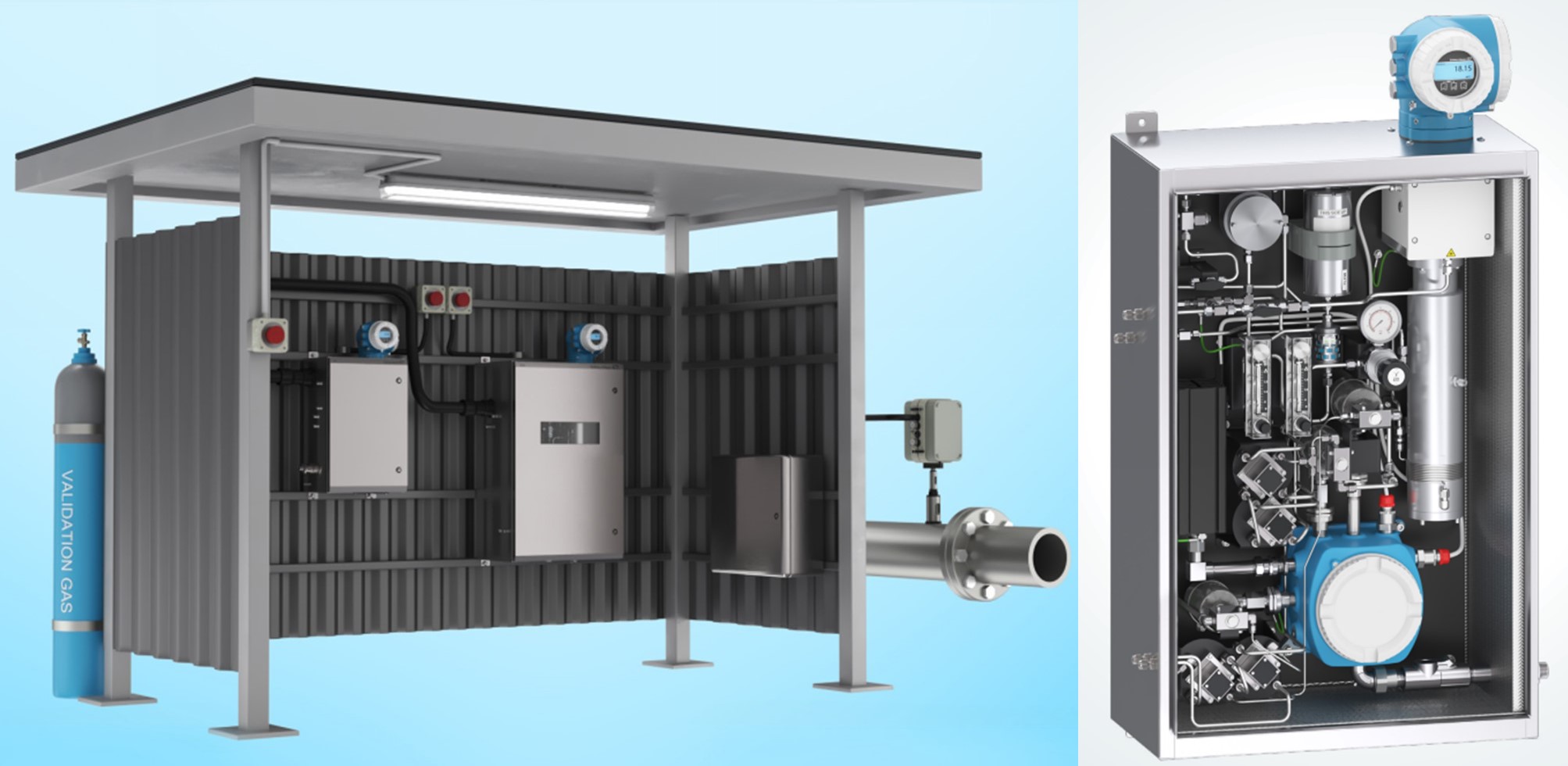

Compared to conventional measurement methods, modern TDLAS technology (Fig. 2) provides several key advantages:

- High accuracy and sensitivity: TDLAS technology enables trace parts-per-million level detection of H2S and other contaminants, identifying and quantifying pollutants even at trace levels.

- Fast response time: This property makes TDLAS analyzers ideal for near real-time monitoring and prompt detection of gas composition changes.

- Interference resistance: The emitted laser spectra are highly specific, minimizing potential interferences from other gas components and sulfurous compounds.

- Low maintenance requirements: TDLAS analyzers contain no moving parts, consequently requiring minimal calibration and maintenance, which increases uptime and profitability.

- Continuous monitoring: TDLAS analyzers enable continuous, online and extractive monitoring of process gas streams, providing near real-time insights into gas quality. This eliminates the need for offline laboratory testing, which introduces reporting delays, sometimes long after sample collection from the process media.

While online TDLAS analyzers generally require no field calibration, scheduled validation using a sample with a known H2S concentration helps ensure ongoing measurement accuracy and compliance with regulatory requirements. Leading TDLAS analyzers provide automated validation features, enabling scheduled or on-demand testing to confirm the analyzer is operating reliably over its entire calibrated range of measurement.

These same instruments often incorporate integrated and onboard performance documentation and calibration records, including NIST-traceable reports, easing regulatory reporting and audit requirements.

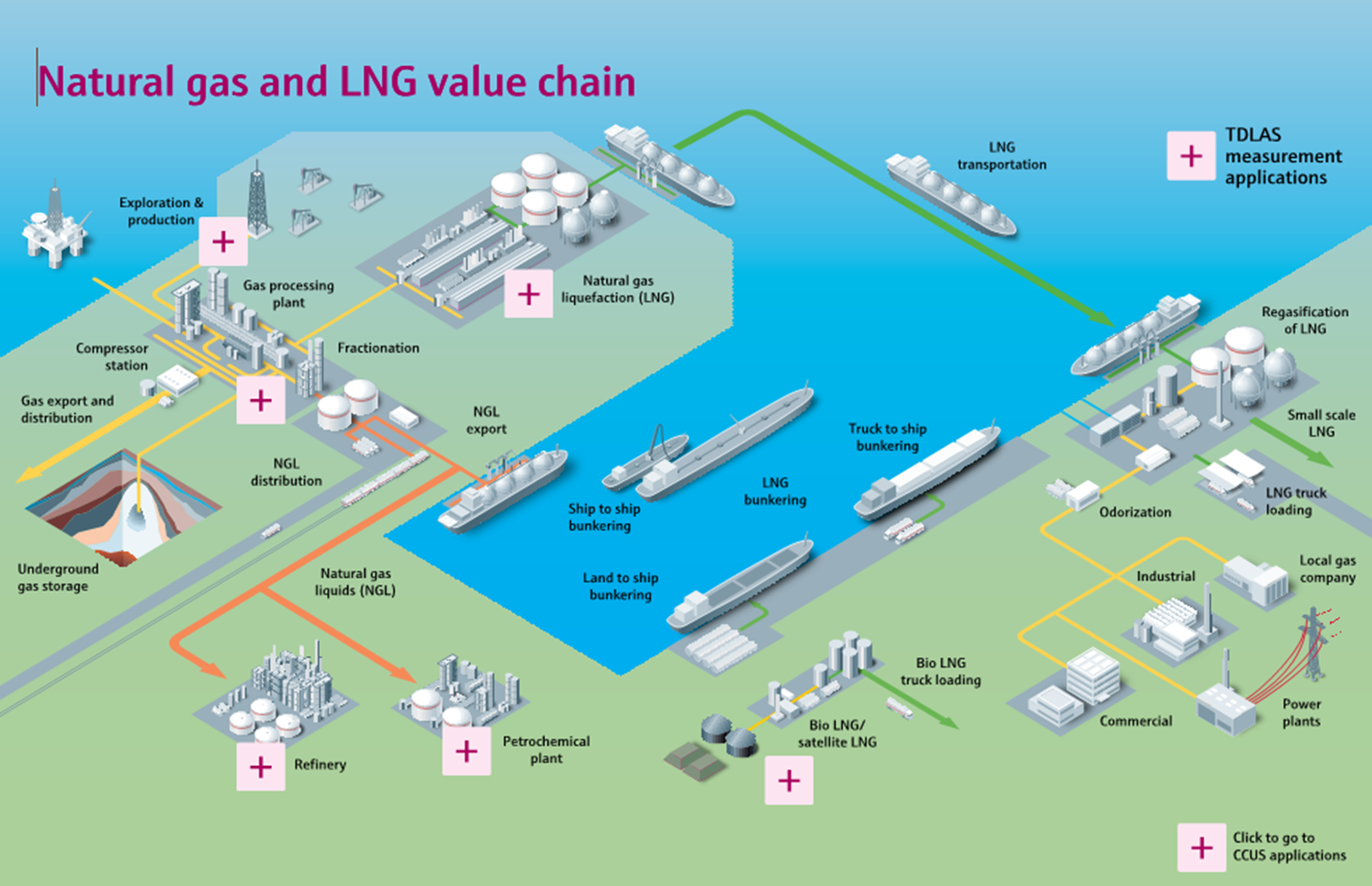

The need for accurate and reliable gas analysis permeates every stage and application in the natural gas value chain (Fig. 3). Typically, custody transfer points are good locations to measure contaminant levels of H2S, H2O, CO2 and O2. Additionally, analyzing pre and post-processing provides understanding of gas quality and equipment health so processors can condition performance and make informed decisions.

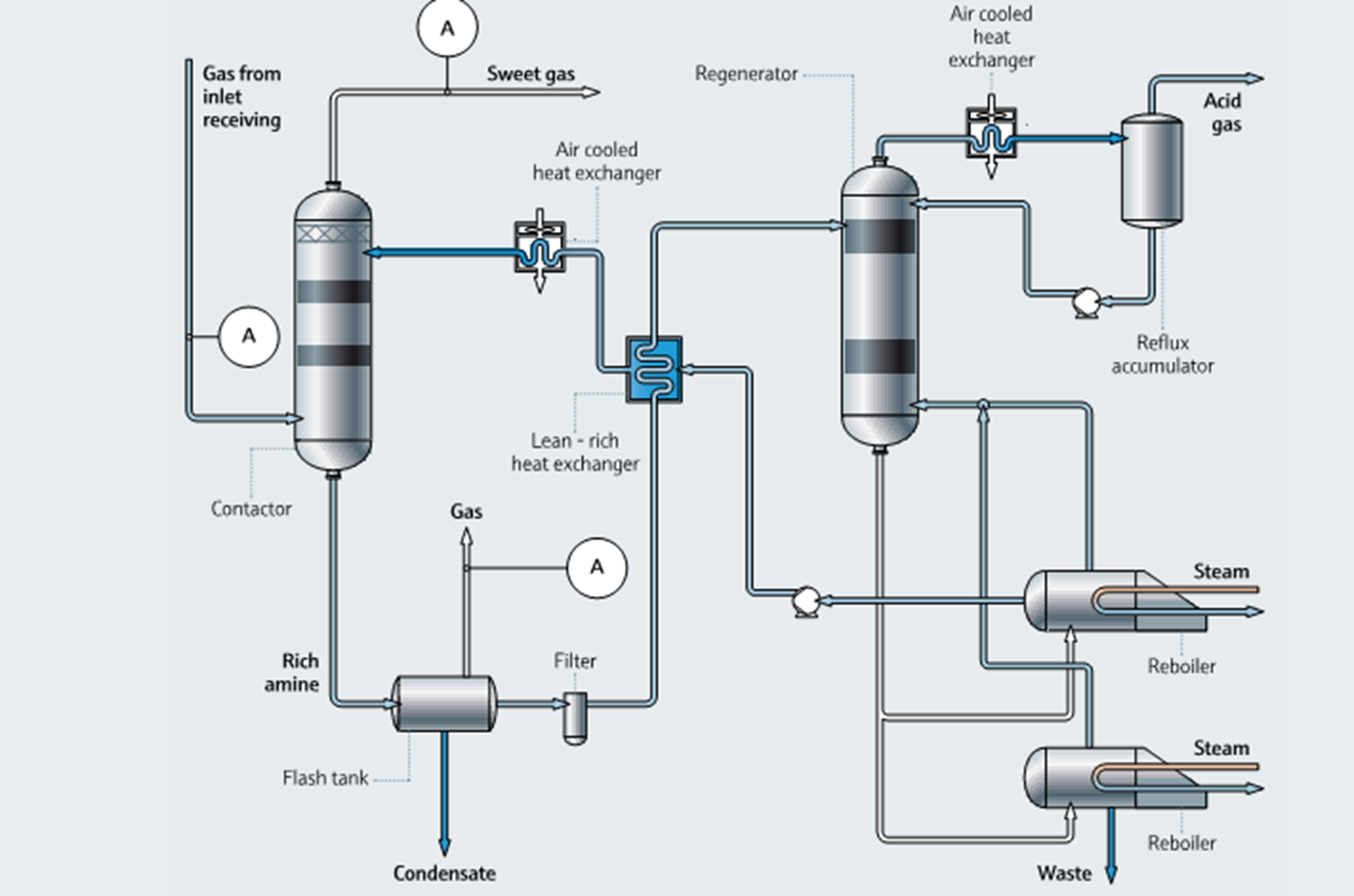

Amine treatment (Fig. 4) is a common methodology for removing H2S, and it requires continuous monitoring of both the sour gas inlet and the sweet gas outlet to optimize process efficiency and ensure effective treatment. Fractionation is also frequently used to boil off impurities, and accurate measurement at each stage provides necessary feedback to the process control system.

Natural gas is in gas phase when transmitted through North American natural gas pipelines, and contaminant removal is critical to prevent corrosion and meet stringent downstream quality requirements. In cases where natural gas is transformed into LNG, TDLAS analyzers monitoring impurity levels prior to the liquefaction process provide removal assurance of H2S and other pollutants. This measurement is also critical for custody transfer applications, ensuring product quality matches what is being purchased.

Refiners frequently rely on TDLAS measurement during flare gas, hydrogen recycle gas in semi-regenerative catalytic reforming, propane and propylene mixing, fluid catalytic cracking and other processes to control contaminant levels and optimize process efficiency. For example, effective H2S removal is required in olefin production to prevent catalyst poisoning and ensure product quality in different refinery applications.

Seamless Quality

In the past, maintaining rigorous natural gas purity in the utility grid was an ongoing challenge. However, today’s advanced methodologies, like TDLAS paired with regimented validation procedures, provide highly accurate, repeatable and reliable measurement of H2S and other contaminants. This, in turn, empowers plant personnel to verify process effectiveness, safety, quality assurance and regulatory compliance, while protecting upstream, midstream and downstream assets from corrosion and other damage.

As the energy landscape continues to evolve, embracing these advanced gas analytics and other innovative technologies is critical to ensure safe, reliable and efficient processes, while minimizing emissions.

Author: Alan Garza is the product marketing manager for the advanced analysis product lines at Endress+Hauser. He began his career with the company as a rotational engineer, where he developed multiple instrumentation technologies. Garza was also part of the inside sales team where he championed gas analytics and developed as an applications engineer. His background also includes business development and operations management. Alan holds a bachelor’s degree in mechanical engineering technology from the University of Houston.

Comments