November 2015, Vol. 242, No. 11

Features

GPR, EM Technologies Offer Rewards in Environmental Assessments

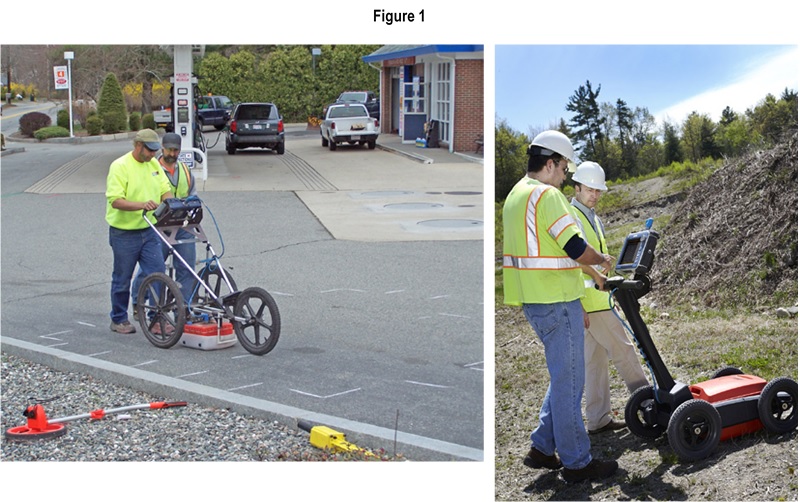

Geophysical surveys can be the bedrock – pardon the pun – of environmental projects, from locating abandoned underground storage tanks (USTs) and utilities, to complex mapping of geology in remedial investigations and finding landfill boundaries and other buried unknown problems.

In the past few decades, a variety of nondestructive testing methods have gained in popularity over expensive and time-consuming drilling and digging for environmental projects. Among these, the method of pairing ground penetrating radar (GPR) with electromagnetic (EM) induction instruments is one that shows great promise in significantly reducing survey time and costs.

Geophysical Toolbox

In the past, most environmental scientists and geologists relied on destructive technologies, including drilling and excavating test pits. Depending on the site and project budget, a survey may require drilling or digging one or two holes for a small site, or more than 30 holes for large sites.

On average, each borehole into the ground on an environmental site costs $5,000-10,000, so costs for drilling or soil sampling can be high. And not only are these methods slow and costly, they merely produce point measurements, rather than a continuous profile.

In response, companies have more recently come to rely on a variety of other nondestructive survey methods. Chief among these is ground penetrating radar (GPR), which sends a tiny pulse of energy into a material via an antenna. An integrated computer records the strength and time required for the return of any reflected signals.

Subsurface variations will create reflections that are picked up by the system and stored on digital media. These reflections are produced by a variety of materials, including geological structure differences and man-made objects such as pipes and foundations. GPR is considered the most accurate, highest resolution geophysical technology.

In general, GPR works best in dry sandy soils with little salt content, but dense clay-based soils are difficult to penetrate with GPR. In some situations, penetration depth may be limited to a few feet or less within clays, whereas targets residing in sandy soils could be detected at depths of 30 feet or more.

A GPR survey can be done at a cost of $1,000-2,000 per day, which means one can cover an entire site with GPR for less than the cost of a single borehole. In light of these clear cost advantages, GPR is now often the preferred method on environmental and construction sites. Instead of boring three or four holes, companies can bore one hole and use GPR to match the results and correlate data across the remainder of the site.

Another method of measuring subsurface conditions is the seismic refraction method, which requires a seismic energy source, trigger cable (or radio link), geophones, geophone cable and a seismograph. Seismic equipment is useful for finding larger features such as soil layers and bedrock depths, especially when deeper information is required.

It works well in clay soils, where GPR is not effective, but it is quite time consuming. To set up and collect the data and then analyze it, only two to four single transects may be collected in a day, which allows for vertical cross-sections into the ground at those locations. By comparison, with GPR one could collect data using 5-foot spacing in two directions and cover an acre per day in the same amount of time.

Along with seismic refraction, a different tool widely used for mapping the depth of soils and rock is electrical resistivity imaging (ERI), which involves placing stakes in the ground and measuring electrical resistance. This tool also works well in clay soil. However, similar to seismic equipment, it takes longer and costs more to get the required data coverage.

Technicians must set up a row of 24-48 sensors (metal stakes) along the ground, typically in a straight line. The line can be as long as needed, but information only flows along that one line. One can collect 80 or more profiles of similar length with GPR in the same time it takes to collect two to four profiles using this technique.

Magnetometers measure the strength and sometimes the direction of a magnetic field. By detecting irregularities in the earth’s magnetic field, a magnetometer can show the location of old tanks and drums, but only those that are made of ferrous material. A magnetometer won’t locate plastic or concrete utility pipes or fiberglass tanks.

Some types of magnetometers, also known as pipe and cable locators, feature a transmitting wand waved back and forth over the ground’s surface, searching for a signal. This does a good job of finding ferrous objects but does not provided accurate depth information like GPR.

Also useful as a reconnaissance technique are electromagnetic induction (EM or EMI) devices, which are based on the measurement of the change in mutual impedance between a pair of coils on or above the earth’s surface. Most EM instruments are comprised of two or more sets of coils. These coils are electrically connected and are separated by a fixed distance.

EM devices can simultaneously examine soil conditions and locate objects found beneath the surface of the earth spatially, but do not provide good depth information.

One of EM’s limitations is that it cannot be used in close proximity (5-20 feet, depending on manufacturer) of aboveground obstructions such as buildings, cars and fences. This makes it less useful for smaller urban sites like gas stations, where there tend to be numerous aboveground obstructions.

GSSI’s Profiler™ EMP-400 frequency domain, EM profiling system (Figure 2), can get within 5 feet of aboveground obstructions and be used to locate metallic targets and measure soil conductivity – even at tighter urban sites.

GPR Gains Popularity

Among all of these options, GPR equipment has become considerably more popular in the last 10 years for environmental projects. It is commonly used for locating old USTs, oil tanks and gas tanks, as well as 50-gallon waste drums filled with chemicals that were routinely dumped on sites in the ’70s and ’80s.

It is also an important tool for mapping utility and product lines, old landfill boundaries, debris pits, buried environmental targets or waste. Finally, GPR is used in remediation investigations to map soil layers and depth to top of water table or bedrock. Contaminants mainly pool either on top of the water table or bedrock, so environmental scientists need to map changes in these features to plan their borings.

The upsurge in GPR’s popularity is largely driven by cost and safety – it is far cheaper and much safer – to do a quick geophysical survey than drill numerous holes in the ground at a significantly higher cost. Cost has come down relative to other technologies, and it is easier to use. Older GPR units required a trained geophysicist to operate – with today’s equipment users can virtually push a button and start scanning.

On some sites, there is a definite cost advantage to combining use of EM with GPR. On smaller projects, such as locating tanks at gas stations, GPR and pipe, and cable locators can easily get the job done alone. But for larger multi-acre projects, for example, multiple areas at old factory sites or large governmental cleanup sites, there can be huge cost savings in using EM first and then focusing the GPR only on “hot spots” or anomalous areas located using the EM.

There are three main reasons EM is a good first tool on large sites: you can collect data much faster; the device does not have to be in contact with the ground (or as close to it) as does GPR; and the EM device’s scanning swath is slightly wider.

Because the EM is carried, rather than pushed or dragged like a GPR device, users can walk faster and maneuver around obstacles more quickly. It is far easier to collect data with the carried EM on sites where there may be overgrown grass, tall weeds, or rocks. Also, an EM can very easily be adapted to be pulled behind an ATV with a trailer or sled setup – again making data collection faster.

Most EM systems also have either built-in or plug-in global positioning systems (GPS), so one does not have to waste time setting up a physical grid (measuring, spray paint, pin flags, and the like).

After using an EM device as the first, fast survey, the user quickly plots that data, which can be done in the field on a laptop in about 10 minutes, and looks for anomalies, targets, and potential soil issues. EM cannot provide exact information on the target’s depth, shape and orientation, but the data is easy to view, process, and even immediately overlay on maps.

GPR surveying is narrowed to only those target areas found with the EM, and the GPR is used to provide information on depths, size and orientation of targets in either 2D or 3D imaging.

Dealing with constantly varying soil or aboveground conditions from site to site is another reason why it pays to have both types of equipment in the company “tool bag.”

For example, EM works much better in clay soils than the GPR, and GPR works much better in sandy soils than the EM. Users often bring both tools to an unknown site.

Lastly, each tool may be better at locating a specific target type – GPR can find both metallic and non-metallic objects, whereas EM is mainly good at finding metallic objects. EM is good at mapping soil changes (either geologic or disturbances such as UST graves), mud pits and potential contaminant plumes, whereas it is tougher to identify those items with GPR.

In some instances, GPR has difficulties with corrugated metal drain pipes because of the design and the way the GPR energy is scattered, whereas EM works well finding such large metal targets.

The cost benefit of pairing the two tools is based on the simple fact that EM is five times faster than GPR on the front end, which lets users focus use of GPR only on identified hot spots.

Let’s look at this calculation using a 5-acre site. GPR takes about a day to do one acre well, so it would take five days to complete the entire survey. EM can complete the site in one day. Starting with EM would, therefore, allow completion of an initial survey in one day, leaving the second day for use of GPR. This cuts the project from five days to two.

The resulting savings can range from 30-60%, depending upon the site. Since GPR/EM consulting fees are typically in the $200-400 per hour range, the three-day savings could be $5,000-10,000.

Overall, using these technologies and adding to business capabilities instantly differentiates one from competitors, expands service offerings in a wide range of applications – construction, environmental, geotechnical, engineering and forensics – and offers the potential to significantly increase revenue for only a small investment.

[inline:GSSI_figure2.png]

The Profiler can get within 5 feet of aboveground obstructions.

Comments