April 2018, Vol.245, No.4

TechNotes

Elsyca V-PIMS Reveals Pipeline Corrosion Mechanisms

The common approach for safe pipeline operation is to include external corrosion direct assessment (ECDA) methodology in the company’s pipeline integrity program. The process relies mainly on field data that is sometimes impossible to obtain or difficult to evaluate.

Elsyca V-PIMS uses in-house developed mechanistic models that provide a 3-D cathodic protection current and potential distribution over the entire pipeline network.

The current demand of individual pipeline sections is determined by the soil corrosivity and coating condition. By integrating soil maps with CP operational settings and available field data, a calibration of the models for the corrosion risk and CP effectiveness is obtained. The Elsyca V-PIMS software is, therefore, a valuable tool in the ECDA process because it:

- increases the feasibility of ECDA in the pre-assessment step by simulating the condition for pipeline

sections where no historic and current data is available - leverages the data from indirect inspection methods by simulating current densities on the pipelines and thus corrosion rates

- justifies sites for direct examinations by simulating the true corrosion protection condition, even under DC and AC interference

- generates automatic reports of ECDA effectiveness and reassessment intervals by simulating corrosion rates is customizable towards client environment.

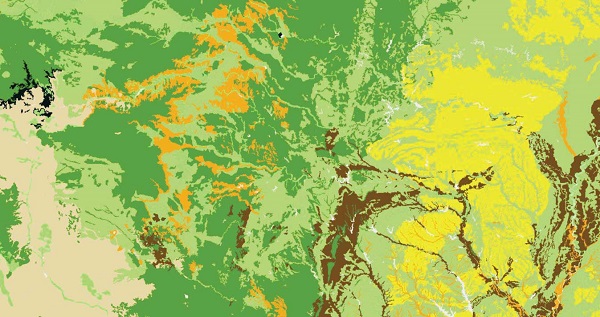

Elsyca V-PIMS visualizes the corrosion health status of large pipeline networks. Instead of a statistical treatment of the field data, the fundamental mechanisms behind the corrosion threats are simulated resulting in advanced corrosion risk assessment and root cause analysis.

The Elsyca V-PIMS simulation technology provides operators with a unique state-of-the-art management system for the design, optimization, monitoring and troubleshooting of the pipeline network’s corrosion protection, leading to a better understanding of the integrity of the assets. P&GJ

Comments