March 2022, Vol. 249, No. 3

Features

Extending Our Capabilities to Integrity and Beyond

By Dr. Mike Kirkwood, T.D. Williamson, UK

In-line inspection (ILI) has long been the go-to method to prove the integrity of pipelines but what happens after the inspection report has been delivered? Does it find a final resting place on a bookshelf reminiscent of the end of the film, Raiders of the Lost Ark (1981) never to be found or is there more gold inside the report than in the Ark itself.

Of course, the answer would normally be yes, but it depends on many things such as the age, service, history etc. - for new pipelines there may be little to see but as a pipeline gets older it can degrade or its service changes or a bad weather event results in damage and this is where the Gold (1983) is.

To go beyond inspection, T.D. Williamson (TDW) has formed a dedicated A-Team (1983) of data specialists and integrity engineers to drill into the data, right down to signal level.

Armed with information from advanced technology such as the TDW multiple dataset (MDS) platform, it is possible to look at anomalies that have been difficult to find in the past. Combining this with previous inspection data enables us to predict degradation and other changes and outline remediation to ensure the pipeline’s economic life.

Growing Pains

One question that is often posed by pipeline operators is, “is any corrosion in my pipeline growing?” The most common way to know is by conducting a corrosion growth assessment (CGA). A CGA compares two or more ILI runs, correlating metal loss changes over time to estimate growth rate.

Alignment is an important element of a CGA, and welds and appurtenances are key features for the process. CGAs are often conducted on ILI runs that were either completed by different vendors, or by using different tool technologies or different generations of the same technology, which is akin to wanting to listen to The Wedding Singer (1998) on your big day to only find a VHS tape and you do not have a player to hear or see them!

Under any of those circumstances, the CGA can be conducted using what is commonly referred to as “box matching,” where anomalies that have been algorithmically sized from the sensor raw data are used for the comparison. However, this can lead to issues in the sizing between the runs and interpretation of The Signal (2007) data by manual processing.

For example, because magnetic flux leakage (MFL) is not a direct measurement, defect dimensions (depth, length and width) are “inferred” from models developed by individual vendors. For example, for some anomalies, a small adjustment in the assumption in width can have a significant impact on the depth and length of a reported anomaly.

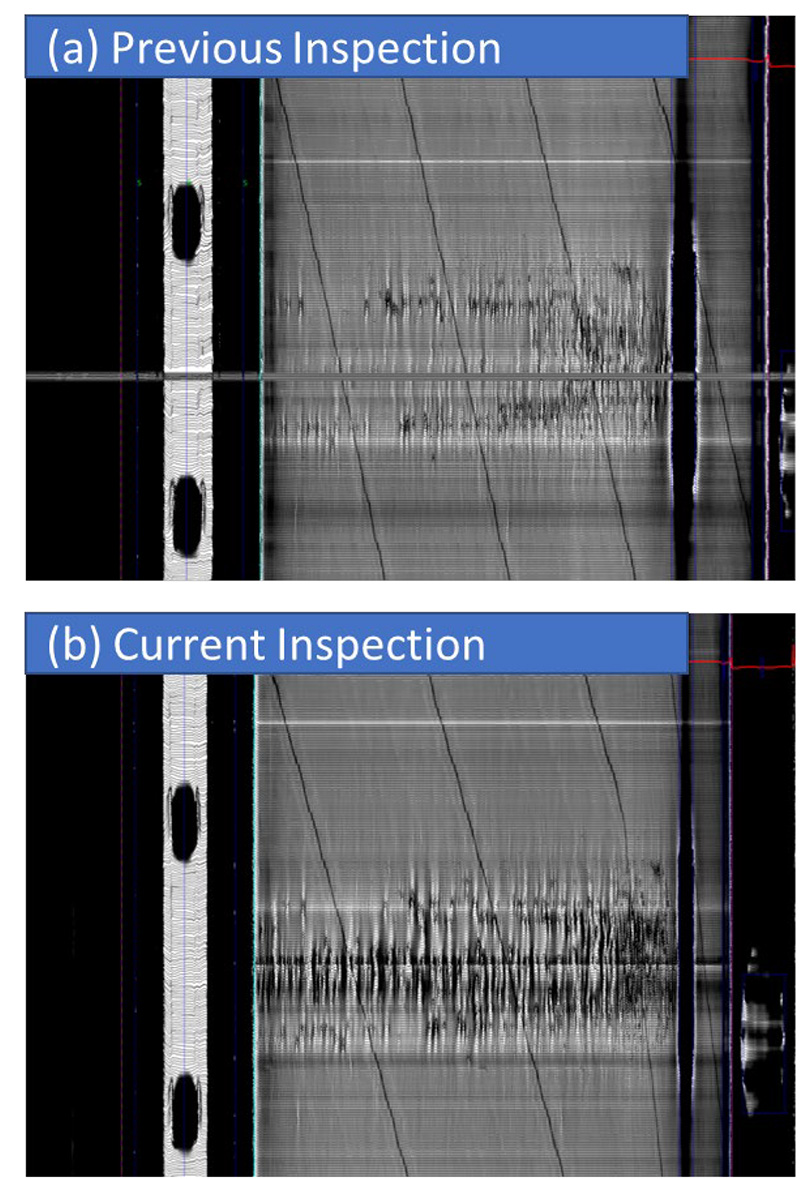

In this case, the best assessment derives from going back to the original signal data and correlating anomaly changes using the raw data, an example is shown (Figure 1).

Conducting a corrosion growth assessment is not always plain sailing. In some cases, anomalies appear to heal; that is, the growth is negative, and metal appears to be deposited. Clearly, this is not possible. These defects need to be assessed as outliers and a statistical viewpoint is required to determine the true distribution of growth.

TDW uses an approach that looks for populations of growth as well as signal-to-signal matching to identify areas where corrosion may be greater than the surrounding base rate. In this way, targeted mitigation decisions can be allocated to zones of high corrosion activity.

Lost Arc

Corrosion is not the only change that can be assessed. When there are geologically unstable areas or when the pipeline has been subjected to severe weather such as wind, rain or a Twister (1996), an inertial measurement unit (IMU) can be an extremely useful tool.

Using IMU XYZ data makes it possible to track changes in curvature, the arc, to ensure that strains are acceptable and to confirm that any remediation measures, such as anchors, line lifting, etc., are working correctly.

For example, heavy rains and flooding recently resulted in damage to an important crude oil pipeline in North America. As the damage could have resulted in adverse curvature or excessive strains detrimental to integrity, the operator chose to shut in the pipeline as a precautionary measure.

TDW had ran an IMU on an MDS tool before the storms. Correlating the “pre-weather” IMU data with above-ground position survey data made it possible to look for any adverse curvature that would need to be remediated before restarting the pipeline.

Once the immediate threats had been negated, a second IMU was ran Under Pressure (1981), lower than normal operations. Comparing the two IMU datasets (pre and post weather) confirmed there were no adverse anomalies to prevent a restart at full operating pressure.

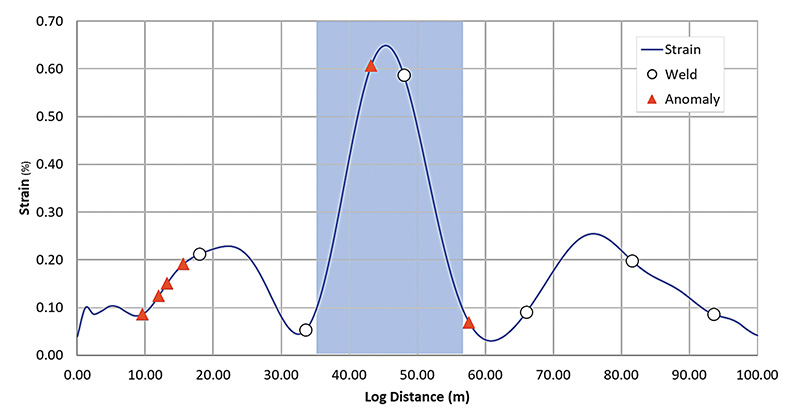

In this case, previous XYZ data was invaluable in assessing the original route of the pipeline and allowing comparison with the new location, enabling the operator to ensure integrity of operations. Back to the Future (1985), the plan is to run the TDW MDS tool to identify combined threats such as metal loss, crack-like features, and so on, co-located with strain events (Figure 2).

One Tree Hill

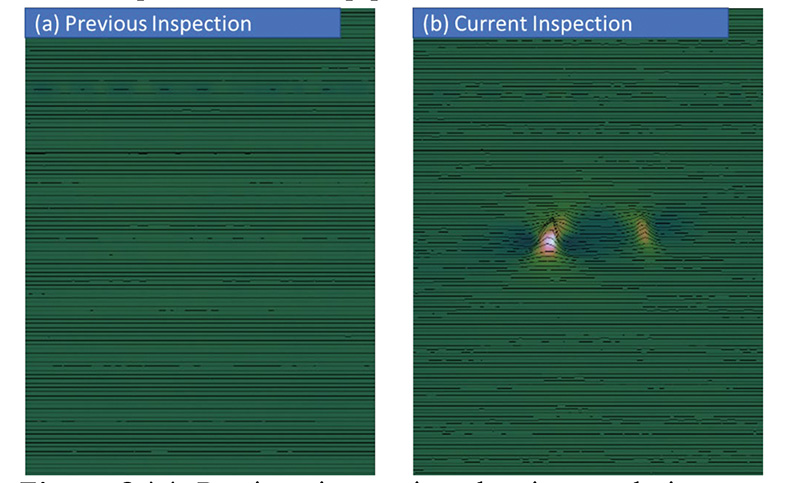

In another recent U.S. project, TDW inspected a liquid line using the MDS tool then conducted a growth assessment. The second inspection revealed a single, new, metal loss feature at which point a pipeline leak was discovered (Figure 3). The failure was thought to be caused by circumferential cracking associated with bending strain.

Fortunately, the MDS technology provided the means to assess the rest of the pipeline for this specific defect type. A solution was quickly delivered and provided the operator with evidence that no other anomalies were present in the pipeline.

To understand the cause of the high strain, TDW looked back through Google Earth’s The Time Machine (1960) for images of the location over several years and made an intriguing discovery. In previous years, a tree grew right next to the pipeline.

But when the MDS inspection took place, only a stump remained. Did the slope shift, compromising the tree and safety of travelers on a nearby freeway or was its demise associated with the presence of the pipeline itself? Whether there was coincidence, correlation or a direct cause, is unknown. But whatever happened, “the truth is out there” (1993).

Real Steel

Another change to consider surrounds pipe material. Obviously, pipe material itself doesn’t change. But the records associated with it can. This can create problems when reconfirming maximum operating pressure, which requires establishing accurate material properties for all segments of the pipeline.

Operators may have some baseline listing of characteristics of the segments of pipe that make up a pipeline, but the pipeline records may not be complete as they may have been lost, retained as paper records hard to track down or changed due to modification, upgrades, diversions. etc.

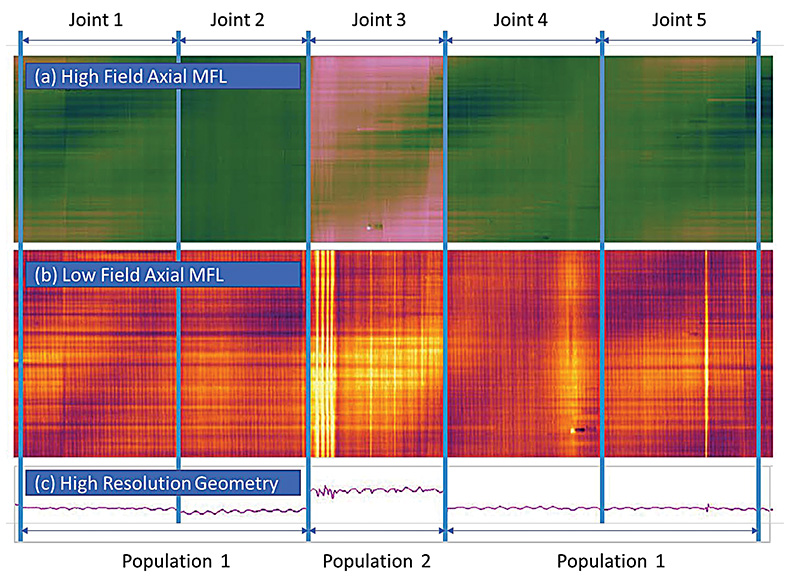

Recent developments in ILI (the MDS tool from TDW) can be used to identify segments of similar pipe based upon observed signal characteristics in the various sensors that comprise the system. More importantly, the ILI data can be used to substantiate the operator’s pipe population assignments through a process called pipe population discrepancy analysis (Figure 4). In essence a gap analysis of known material data correlated to ILI signals then backed by in field or laboratory verification.

Recently, TDW has been working with an operator Out of Africa (1985) to establish material records for a key pipeline supplying fuel from the coast to the interior of the country. The project involved the use of the MDS tool to establish populations of known material grade and to locate any spools that did not meet the required specification for operation.

The project was a success and established the pipeline met all the minimum required specifications and operations were not impacted.

This segment of pipeline has two populations of pipe (population 1 and 2). The populations can now be correlated to records fill gaps in the material verification

Hard, Ain’t It Hard

Hard spots have been known to exist in pipelines for many years. Hard spots are classically defined as a localized increase in hardness produced during hot rolling of steel plate because of localized cooling. Hard spots are often considered by pipeline operators as non‐injurious, stable features.

Many hard spots will reside in the pipeline for its life without any additional threat. However, the locally hardened material does pose an increased risk for potential cracking and hence can be injurious during operations, especially if additional threats exist such as the presence of hydrogen. Cracking can occur at hard spots that eventually grow over time that can lead to pipe failure.

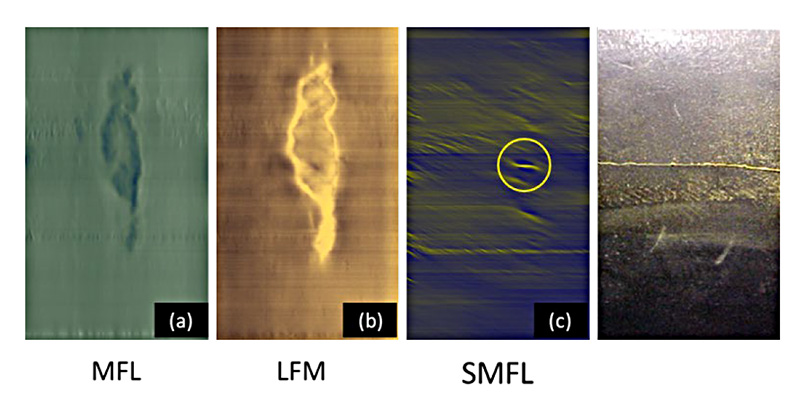

TDW has been using the MDS tool to detect hard spots using a low field magnetic (LFM) sensor to detect permeability changes in the steel to assess material variations such as hard spots. Figure 5 highlights a hard spot location which has three element of sensor data all from the single MDS tool.

The first, (a) shows the magnetic flux leakage (MFL) signal and highlights that the hard spot has some wall thickness change which is not always the case. The second, (b), shows the LFM signal where the extent of the hard spot can be seen clearly, suggestive of a Ghost (1990).

The third, (c), shows the spiral magnetic flux leakage (MFL) data highlighting a crack-like feature directly within the hard spot. The final image highlights a crack-like feature in the hard spot. Further analysis can be conducted to “map” the hard spot and provide hardness values hence enabling a prioritization of these features.

In a recent project with a European liquid pipeline operator, a crack-like feature was found in a hardened area in a spool of a seamless pipe. This was an unusual feature given hard spots are seen more commonly in seam welded pipe.

The MDS tool mission was to find any other likely anomalies and although some areas of local hardness were found, no crack-like features were evident and hence the pipeline was proven As Good as New.

Conclusion:

At TDW, we are using new algorithms and advanced ILI technology to open new views of pipeline integrity.

We have been extending our capabilities to assessing non-axial stress corrosion cracking utilizing magnetic and IMU data, prioritizing wrinkle bends where there is the potential for cracking, looking for possible cracking in welded saddle branch connections, as well as providing dent gouge discrimination for advanced mechanical damage prioritization.

Combining our passion to assist the pipeline industry with new tools and methods, we’re going To Integrity And Beyond (1995).

Author: Dr. Mike Kirkwood (Ph.D., MBA, BEng, CEng, FIMechE, ASME, AMPP) Director, Integrity Engineering Solutions, has more than 30 years of experience in the nuclear, power generation, water and the oil and gas industries. With T.D. Williamson since 2006, he is a subject matter expert in all forms of structural integrity with a specialty in pipelines. He has written numerous international papers on structural integrity, risk and pipeline inspection, repair and rehabilitation.

Comments