May 2023, Vol. 250, No. 5

Features

PRCI Report: Bridging Energy Infrastructure Opportunities with Today’s Needs

By Anita Vigilante, Communications Specialist, Pipeline Research Council International (PRCI)

(P&GJ) — We are at a crossroads, both in the U.S. and globally, as the world works to develop new sources of energy. As the next generation of energy is becoming reality, it is critical to acknowledge the vital role that the current pipelines and associated assets will play in transporting and storing these commodities.

Pipelines are the safest mode of energy transportation and are the backbone of our nation’s energy infrastructure. Pipeline Research Council International (PRCI) and its members continue to innovate this network toward zero emissions and 100% reliability through the many projects that are being developed and performed.

These improvements range from addressing the challenges associated with transporting and storing new fuels to leak detection to fitness for service.

PRCI was founded in 1952 to solve key challenges that faced the safety and integrity of the energy pipeline network in the United States. Over the past 70 years, it has grown into a global non-profit organization that performs the research needed for enhancing the safety and integrity of the global pipeline network and reducing its environmental impact.

The PRCI community is comprised of the world’s leading pipeline companies, and the vendors, service providers, equipment manufacturers, and other organizations supporting the industry.

The mission for PRCK is to collaboratively deliver relevant and innovative applied research to continually improve the global energy pipeline systems. Members investigate the challenges of corrosion, design, materials, construction practices, compressor and pump stations, integrity, inspection, rights-of-way surveillance and monitoring, subsea assets, underground storage, and the measurement of the products within the system.

PRCI is recognized around the world as a unique forum within the industry for delivering immense value to its members and the industry – both quantitative and qualitative – through the development and deployment of research solutions to improve pipeline safety and performance.

Tomorrow’s Opportunities

Not surprisingly, PRCI has been in the forefront of the transitions to new fuels. In the 1980s, it performed some of the early research done on hydrogen transport and storage. In the late 1990s, PRCI research enabled the industry to safely transport ethanol. PRCI has researched the transportation of biofuels, renewable natural gas, hydrocarbons, and other sources of energy for many decades.

Through private and co-funded work with PHMSA, it has led to many key recommendations to enable the transport and storage of these fuels. As the push to include these emerging fuels moves forward, the focus on the safety and integrity of these vital pipeline system assets must continue for the mosaic of energy that will be needed to meet the future demands.

To be efficient and effective, PRCI works closely with the U.S. Department of Energy (DOE), Pipeline & Hazardous Materials Safety Administration (PHMSA), Environmental Protection Agency (EPA), National Institute of Standards and Technology (NIST), Canada Energy Regulator (CER), Natural Resources Canada (NRCAN), and Environment and Climate Change Canada (ECC Canada) to assist members and the industry to make the pipeline infrastructure safer.

In 2020, PRCI created the Emerging Fuels Institute (EFI) to answer the questions needed to safely transport and store hydrogen, hydrogen blends and renewable natural gas. The first efforts of this worldwide collaboration of over 20 companies and four corresponding global organizations are focused on which pipeline materials will be best suited for hydrogen service.

Work that has already been done in Europe and Australia is being leveraged to assist the North American energy pipeline operators. Workshops have assisted in coordinating the efforts within CER, NRCAN, DOE and PHMSA. The PRCI EFI is a part of the DOE HyBlend effort to understand pipeline properties. Research is now at the point that it needs to progress to full-scale testing to provide a fuller level of confidence in the understanding of hydrogen’s impact on the pipeline systems, an area that would be well suited for a public – private partnership.

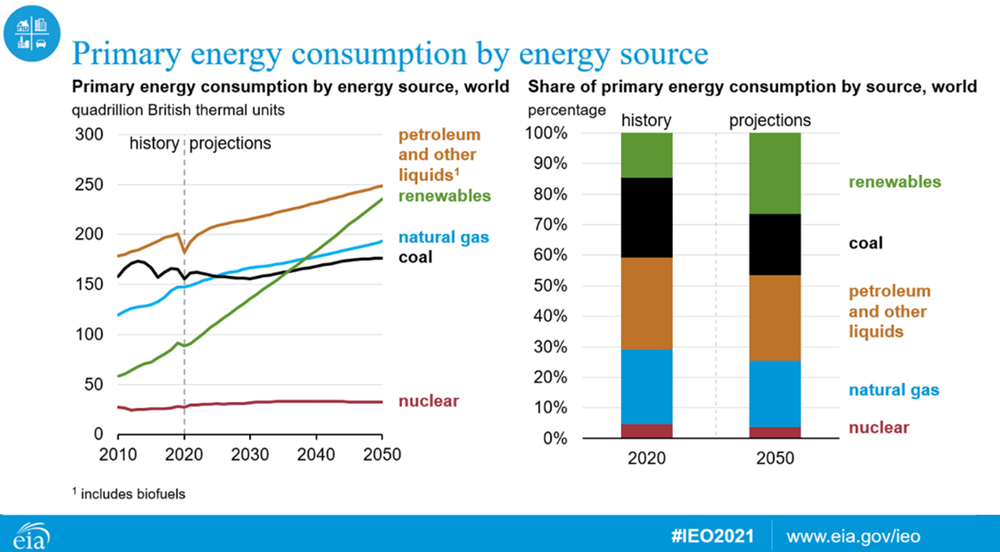

According to the Energy Information Administration (EIA), 68% of the domestic energy consumption is supplied by petroleum and natural gas; the majority of this energy is transported by pipeline. To transition that consumption to electrical energy would require enormous infrastructure changes, including a massive build-out of the electrical grid and corresponding renewable energy development.

Not only would this take time and land, but it would also demand large amounts of energy, resources, and produce significant greenhouse gas emissions for steel, copper, aluminum and cement to build out the electrical infrastructure. Furthermore, applications that require high-density fuels, such as the airline industry, are unlikely to ever be electrified. Clearly, the pipeline infrastructure will continue to be a key part of the new energy economy.

This understanding drives the development and use of alternative gaseous and liquid fuels such as hydrogen, biogas and biofuels. Prior to the successful implementation of these emerging energies, hydrogen has the most research gaps to address.

Some of the existing pipeline system is suitable for transporting hydrogen, but for the remainder, additional research is needed to understand the material limitations of pipelines in hydrogen service under actual conditions, including pressure cycling. For example:

- Additional research is needed in the equations of state for hydrogen in blends with natural gas;

- More development is needed for technologies that can identify material properties from within the pipe

- Better tools are needed to detect the development of cracks in pipeline steels

- Further research is needed in developing technologies that can optically identify hydrogen leak emissions;

- Research gaps need to be identified and addressed to facilitate the underground storage of hydrogen in depleted and aquifer driven reservoirs

- Full-scale testing in a safe and controlled environment must be done to expand upon the excellent small-scale testing that the DOE has performed on hydrogen material compatibility.

According to H.R. 9349, the Next Generation Pipelines Research and Development Act, over 50% of the industry’s asset base is at least 60 years old, yet the current network can be part of the energy transportation and storage backbone for years to come, if well maintained.

The goal is to maximize the safety and reliability of the pipeline systems while minimizing the corresponding environmental footprint. This process is underway using the PRCI Technology Development Center (TDC) in Houston, Texas.

The TDC facility opened in 2015 and offers over 1500 pipeline samples from around the world to test and develop tools, processes, and associated people for enhanced pipeline safety. In-line inspection (ILI) tools are used to assess the integrity of pipelines, and three projects will be completed in 2024 that will provide an understanding of the current state of the tools and what is needed to elevate their capabilities.

A portion of the TDC was co-funded by PHMSA to jointly research the effect of mechanical damage on pipelines. PRCI recently met with PHMSA Deputy Administrator Tristan Brown, U.S. Rep. Lizzy Fletcher and U.S. Rep. Shelia Jackson Lee to discuss the opportunity to receive pipeline samples from failure investigations. The continued partnerships with PHMSA, DOE, NIST and others is welcomed.

Today’s Energy Needs

The number one priority in a pipe failure and any product released is to be able to locate and isolate the source as soon as possible. Leak detection is one key focus area for PRCI.

An area of enhanced investigation is devices installed along the pipeline, such as handheld sensors, aerial sensors including fixed wing, helicopter and unmanned aerial vehicles, and even satellite-based sensors. This focus aligns with PRCI’s commitment to reduce the environmental impact of pipeline systems.

Similarly, the opportunity to reduce greenhouse gas emissions is another key area of PRCI research. From the emissions associated with pipelines and those at compressor pump station facilities, members are working to identify and reduce as much as possible as soon as possible.

A continuing challenge to the pipeline industry is corrosion. Recent data shows the internal, external, and stress cracking corrosion are the second leading cause of pipeline incidents. Research to prevent, detect, and mitigate corrosion is vital to extending the life of these assets. PRCI continues to work enhancing the tools used to determine the fitness for service of current assets and any new pipeline systems being developed.

With increased rainfall and earthquakes, the potential for movement around and of pipelines has increased. Geohazard threats introduce new stresses and strains to the systems that need to be better understood. PRCI is exploring opportunities to modify construction practices to better prepare for such events. Advanced sensor technologies are also being developed and verified.

Data and data management is a growing opportunity for the energy pipeline industry. In 2016, PHMSA was directed to explore the creation of a voluntary information sharing (VIS) program for the pipeline industry. The final report laid out a strong plan for advancing the use of data, yet it was not advanced in Congress.

In parallel, PRCI had already begun to develop the Virtual Technology Development Center (VTDC). It has taken PRCI time to gain the needed momentum but is bringing together data from several projects and beginning to enable the industry to contribute data.

To make significant strides, a public-private partnership like the one the Federal Aviation Administration (FAA) developed to enhance air safety must be established. The FAA model was the seed for both the VIS effort and VTDC. Data sharing to enhance industry decision-making is the next big step for safety.

The bottom line is that the energy pipeline industry must maintain the highest standards of safety, environmental commitment, efficiency and reliability while embracing the flexibility needed to advance the net zero emissions goal.

PRCI members help navigate these areas of concern by identifying the challenges associated with the anticipated timelines for transition. Expanding access to technical expertise, removing natural defects from service and providing funding that improves the acceleration needed for industry to respond to the rapidly changing environment.

PRCI leads the research industry to provide sound and dependable guidance, and to emphasize a concerted effort of industry, provider and government in aligning and supporting each other in the prioritization.

Comments