February 2024, Vol. 251, No. 2

Features

Evacuation Technologies to Reduce Methane Releases During Pigging

By Jeff Witwer, PE1, Rita Hansen, CEO, Mitch Jacobs, Business Development Associate, Onboard Dynamics, LLC

Due to the strong global warming potential (GWP) of methane (CH4), there is increasing attention on reducing its releases (both unintentional and intentional) into the atmosphere.

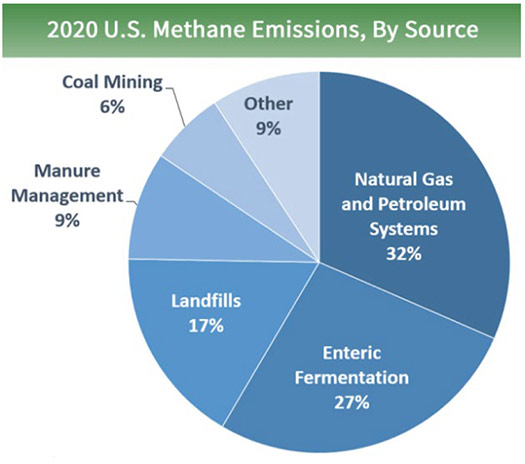

Although fossil fuel production and use might only be responsible for less than 32% of the methane released into the atmosphere on a global basis (Figure 1), it is viewed by many as the source that can be most effectively and economically controlled.

The other major sources are naturally occurring and highly diffused. The seriousness and urgency around reducing methane emissions were both evident in the recent legislation of the Inflation Reduction Act (IRA), on Aug. 16, 2022.2 The bill contains a fee on methane emissions, which marks the first time a fee has been levied on any greenhouse gas.

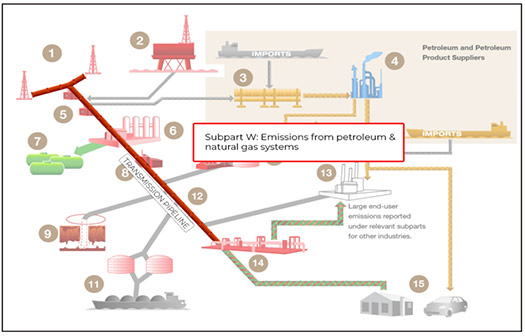

Fees will be levied based on individual facilities (defined as sources of methane releases that are co-located and owned or operated by a single entity). These facilities report to the EPA’s Greenhouse Gas Reporting Program (GHGRP) under Subpart W3 (Figure 2). Some natural gas distribution facilities are not subject to the fee under the IRA, even though they may be reporting to the GHGRP under Subpart W.

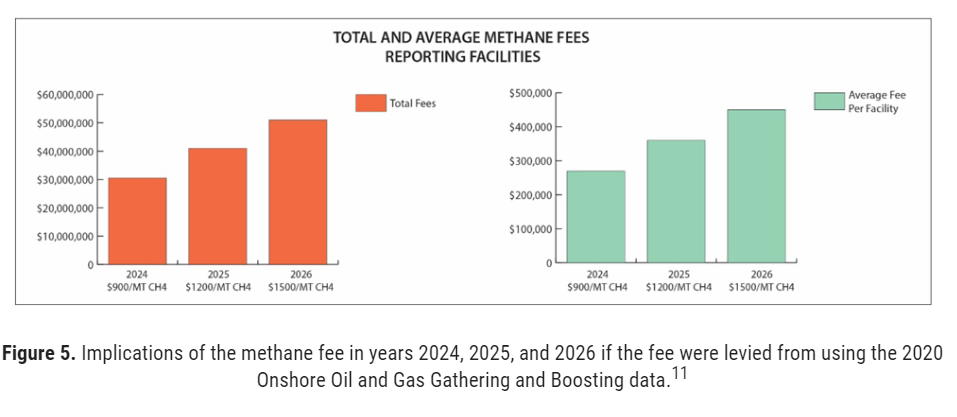

Other facilities that are also not subject to the fee are those reporting under Subpart W, whose facilities emit less than 25,000 metric tons (MT) of carbon dioxide equivalent (CO2e) per year. Eligible facilities reporting to the GHGRP under Subpart W will begin to face a fee for emissions in calendar year 2024, starting at $900/MT CH4. In 2025, the fee increases to $1,200/MT CH4. In 2026, the fee continues to increase to $1,500/MT CH4.

The magnitude of these annual fees is clearly significant. For example, if the natural gas were valued at $10/MMBtu as a fuel, the value of any recovered methane is about $500/MT.

Another piece of regulation driving the need to reduce methane emissions is a collection of several specific provisions from the Protecting our Infrastructure of Pipelines and Enhancing Safety Act (PIPES ACT) of 2020.5

The PIPES ACT requires that companies “consider the environment” when designing or modifying their Leak Detection and Repair (LDAR) plans. The significance of this language is that if leaks are detected and repairs ensue, the pipeline needs to be evacuated of the natural gas prior to performing repairs. Past common practice would be to blow down the pipeline prior to performing the repair, thereby resulting in the release of methane into the atmosphere.

The PIPES ACT also requires that companies update their operations and maintenance plans to include protection of the environment and replacement/remediation of pipes known to leak. The PIPES ACT includes provisions for the DOT to report to Congress on technologies and practices to prevent or minimize the release of natural gas during planned repair/replacement or maintenance and venting/blowdowns.

Both the IRA and PIPES ACT are compelling natural gas companies to reduce their emissions, through regulation and economic penalties for non-compliance. Another driver toward reduced emissions is a company’s public stance, as it relates to Environmental and Social Governance (ESG) goals — an increasingly important metric for both employees and shareholders.

In 2021, we performed an “Emission Reduction Goals Assessment” to discover how ESG policies drive company commitment to reducing methane emissions. Using rankings from the American Gas Association (AGA) of the top natural gas companies by residential and commercial volumes, our work found that the top 20 companies had established goals for reducing greenhouse gas emissions6.

Of these 20 companies, nine had goals for net-zero emissions with varying end dates, and 19 of the 20 were affiliated with either the EPA’s Methane Challenge, the EPA’s Natural Gas STAR Program or the ONE Future Coalition. These affiliations all require their members to demonstrate — by practice, technology or reporting — the reduction of methane emissions.

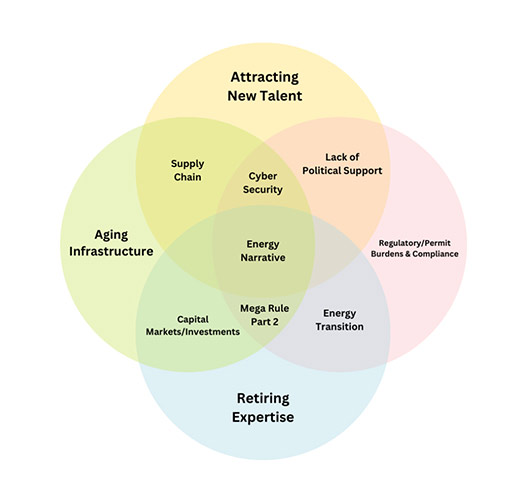

As important as government regulations, fees and corporate ESG goals might be in motivating the natural gas industry to reduce methane releases, there is yet one more factor that might be even more dominant: the challenge of recruiting new employees. The Lamar University Center for Midstream Management and Science recently published its annual survey of the “top ten issues facing the midstream industry in 2023,” Figure 3.7

The highest rated concern — “attracting new talent” — was described as follows: “Many young people are not interested in working in a vilified industry seen as ‘dirty’ and undesirable and low tech, where long-term employment prospects are uncertain.” It would seem obvious that unnecessary methane releases through company operating practices would be a prime example of such challenges.

Implementing best practices to capture and recover methane during regular pipeline maintenance operations is a logical step forward to attract future talent.

Pipeline Emissions

To better understand how these methane fees and regulations might impact pipeline pigging operations, we turned to the EPA’s Facility Level Information on Greenhouse Gases Tool (FLIGHT) Data (2020) for the Onshore Oil and Gas Gathering and Boosting segment.

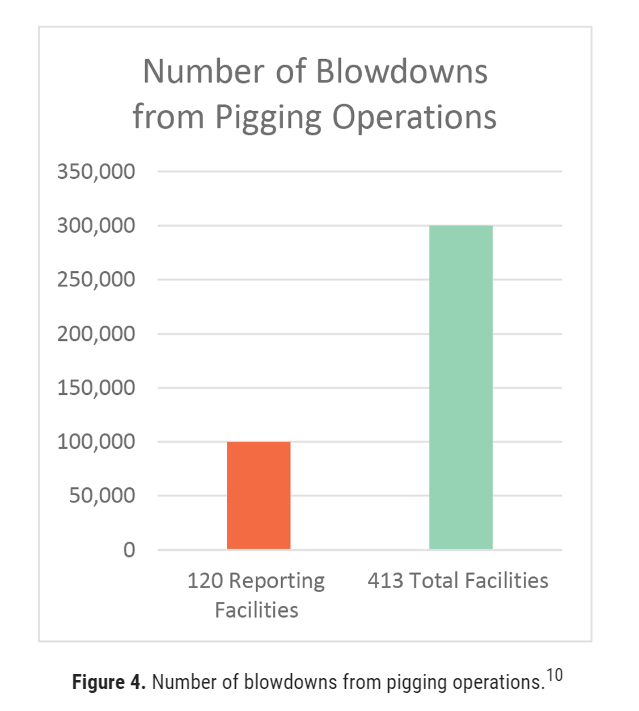

Using this data source, we estimated the number of blowdowns from pipeline pigging operations (launcher and receiver). The data set included 413 facilities of which 120 reported blowdowns from pigging operations (Figure 4).9

Based on our analysis of the EPA data, there were approximately 100,000 blowdowns from pigging operations reported amongst these 120 facilities — an average of about 800 blowdowns per facility. If we were to extrapolate that metric across all 413 facilities, we would estimate that there are over 300,000 blowdowns from pigging operations within the gathering and boosting segment of the natural gas value chain on an annual basis.

It is important to note that not all emissions from pigging operations can be eliminated by using natural gas capture/recompression technology, since use of any equipment itself releases CO2 gases. For example, we use integrated sensors and data acquisition systems in the GoVAC FLEX system (verified by experimental data from test cell data) to calculate NET emissions reduction from actual, individual evacuation projects, to ensure accuracy and credibility of environmental performance reports.

This will be further discussed in the following section. Blowdowns from pipeline pigging operations will also have implications, in relation to the IRA’s methane fees. Of the 120 facilities that reported blowdowns from pigging operations, 94% exceeded the facility level threshold of 25,000 MT CO2e emissions, making them eligible for the methane fee. The blowdowns from these facilities (including those associated with pigging operations) resulted in over 30,000 MT CH4 emissions.

The table (Figure 5) illustrates the implications of the methane fee in years 2024, 2025, and 2026 if the fee were levied using the 2020 Onshore Oil and Gas Gathering and Boosting data.

Compression Technology

There are many factors that determine the success of the natural gas evacuation methods used on a pipeline pigging operation project. In this section, we will discuss key factors for success in performing pipeline evacuation and reducing methane releases. We will then present the results from two pigging operation projects.

Safety

The number one goal of any firm operating in the natural gas industry should be that everyone goes home safe and unharmed. Safety is governed primarily by the following national codes: OSHA and CFR Title 49, parts 192 and 199. In addition, there are state and local safety and labor related codes that must be satisfied. As part of becoming qualified to perform work on a job site, an audit of safety programs, procedures and training standards is performed against industry standards.

The audit covers topics such as a firm’s safety policy, hazard risk assessment process, hazard communication process, hazardous material handling, fire safety, personal protective equipment, and many others. It should be the perspective to engage in audits with positivity and with consideration that the process is designed to improve safety and reduce the likelihood of harm.

Equipment Specifications

Three key factors must be considered in selecting equipment for an evacuation project: the volume of natural gas that is to be recovered, the available time for the evacuation and the specified inlet (suction) and outlet (discharge) pressures. The first two factors, volume and time, determine equipment capacity and project scheduling.

The last factor determines the technical fit between the evacuation equipment and the project requirements (including desired recovery percent and minimum drawdown pressure).

Access, terrain

Some projects involve tight spaces or difficult terrain. It is surprising how many projects are located next to a busy, and sometimes, narrow highway, making a small and efficient equipment footprint advantageous (Figure 6). These factors must be considered when selecting evacuation equipment.

Logistical Considerations

In addition to providing for the positioning of the project equipment itself, the evacuation compressor from some vendors will require access for ancillary equipment, such as an air compressor or genset. Siting and access for this equipment and its operators will also need to be provided. Such equipment might also require access to permit refueling if it is powered by a diesel engine.

This, too, must be provided for. Integrated, self-contained systems — which are powered by natural gas and have integrated data acquisition systems — do not have this additional access concern.

Scheduling constraints

Operators need the ability to quickly connect and purge the components on a jobsite. This includes a low complexity set of connections, and a small equipment footprint.

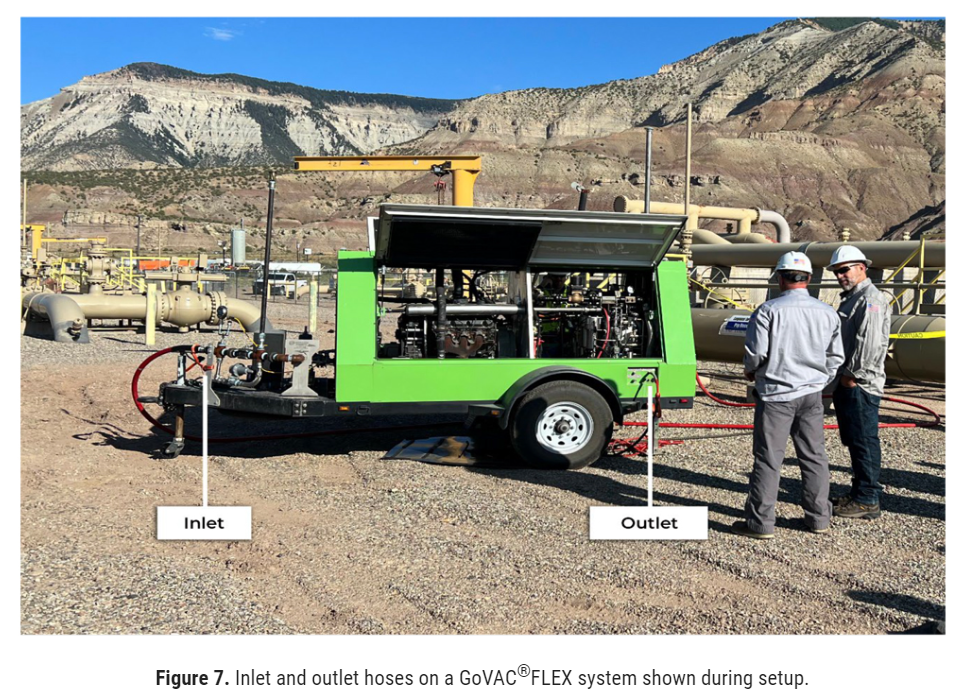

All these factors contribute to getting the pigging operation efficiently completed on both the launcher and receiver sides. The project example (Figure 7) illustrates one piece of equipment, one inlet natural gas hose and one outlet natural gas hose. No other equipment was needed on this project, which greatly reduced setup and breakdown times.

Formalized Procedures

It is important to have a rigorous set of operation procedures that are both followed every time and continuously improved upon, to be safe and efficient in completing pipeline evacuation projects. The basic steps for safely completing any pipeline evacuation project are:

- Before arrival, plan the project including the following topics: safety procedures, site hazard assessment, site layout, connection points and general parameters for the project.

- Upon arrival, gather the team and conduct the safety tailgate meeting.

- Position the equipment in a safe location and per the site safety plan.

- Inspect the site and the equipment for any abnormalities or hazards.

- Connect the two inlet and outlet hoses.

- Perform purging steps on the inlet natural gas, compressor, and outlet natural gas segments.

- Perform leak checks.

- Set the equipment automatic shutdown pressure (with two-person concurrence).

- Final team safety signoff and engage the compressor.

- Monitor the compressor pressures and temperatures during evacuation.

Training

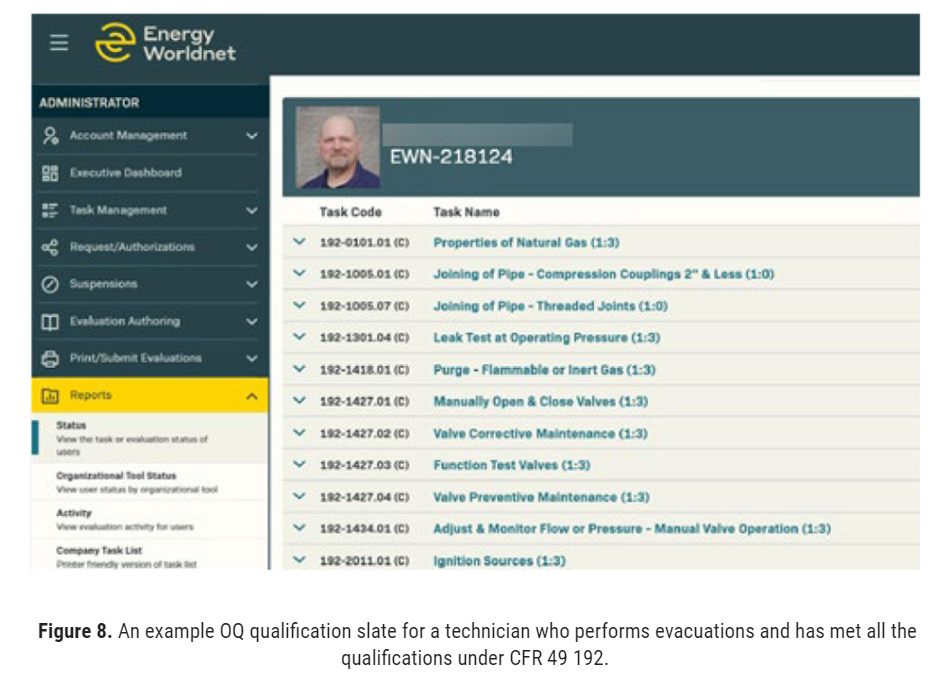

Standardization is a topic that occupies a tremendous amount of time for both the safety and operations departments in this industry. To be considered safe and competent to operate on a pipeline project job site, technicians must complete a set of agreed upon Operator Qualifications (OQs) in advance.

This list is evolving with the relatively new practice of pipeline methane capture and recovery. OQs are training courses that include a self-paced online training course, a knowledge evaluation (usually an online quiz), and a skills evaluation by a certified Master Evaluator. The training standards for this space are ASME B31Q Pipeline Personnel Qualification and CFR 49 192.

Case Studies

The following are two examples of methane capture and recovery technology and emission profiles from actual pigging.

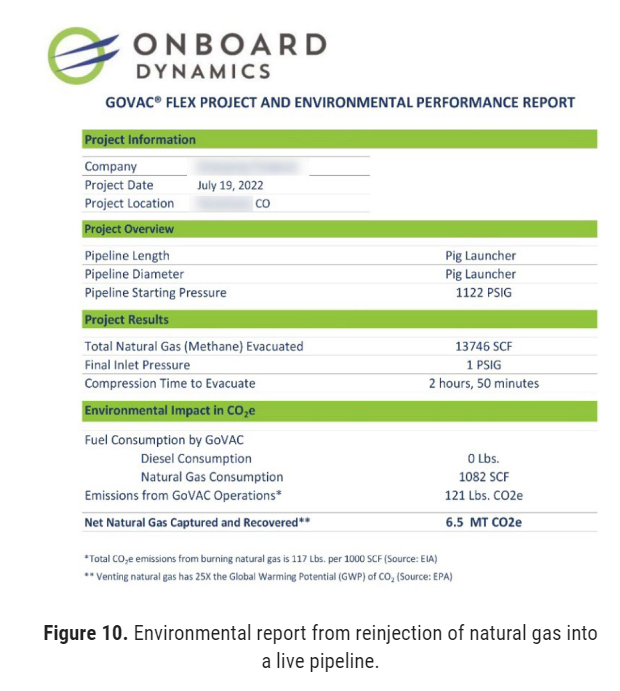

Cast Study 1: A common case for pipeline evacuation projects is one where a nearby pipeline reinjection point is available for cross-compression and transfer of the natural gas.

One pipeline safety and integrity concern with the use of evacuation technologies is the possibility of over pressurization, especially when reinjecting evacuated natural gas into a live pipeline. In such cases, it is beneficial to pre-determine the optimal maximum pressure at some point below the MAOP prior to the start of a project and ensure the equipment operates within those limits.

Through sensor technology, the operator can mitigate over pressurization by automatically shutting down the equipment if the maximum pressure threshold is reached. The data in the Environmental Report (Figure 10) is securely archived and fully accessible for auditing.

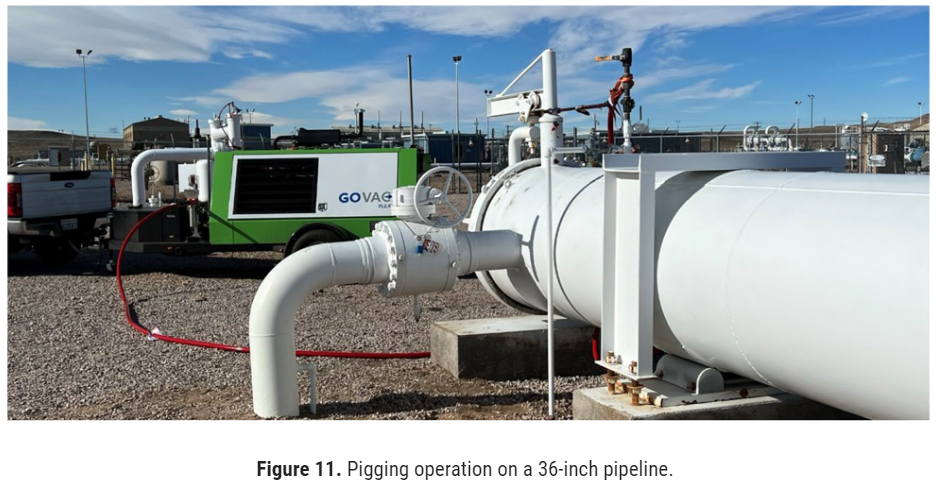

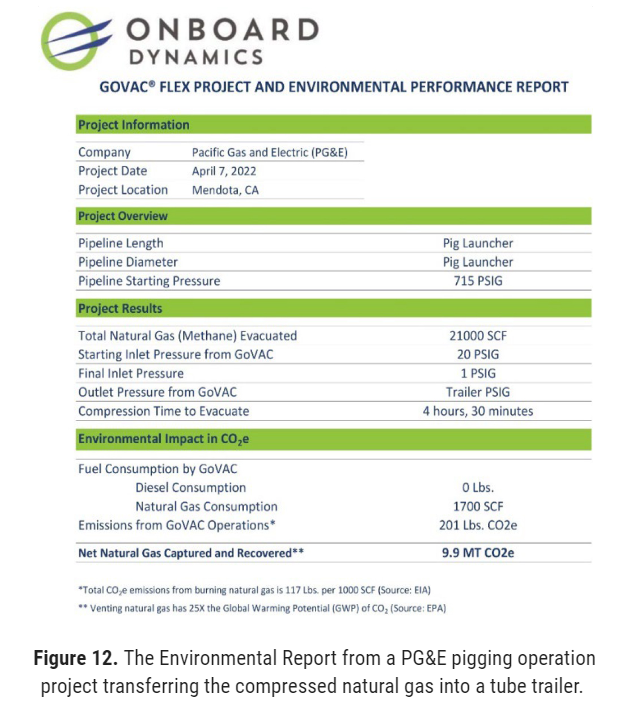

Case Study 2: This case involved PG&E pig launcher evacuation into a high-pressure tube trailer. A characterization of this job was the lack of nearby natural gas reinjection points for the captured natural gas. As such, the specified equipment needed the capability to fill a portable tube storage system and reach the associated high outlet pressures (e.g., 3,600 psig).

Also, from a throughput perspective, the volume of natural gas to be moved with the estimated starting pressures made the selected GoVAC FLEX system a good fit. The project Environmental Report (Figure 12) fully documents the results of this project. Importantly, the data shown here is stored and fully retrievable and is available for audit and verification by the pipeline operator and any authorized auditing or regulating agency.

Planning, analyzing and securing a digitized evacuation. In this section, we’ll discuss an analytical approach to estimate the volume of avoided methane release (and corresponding CO2e) from a pigging operation.

However, steps to avoid methane release will themselves require that carbon dioxide (CO2) be released by the compressor recovery equipment used, so we’ll also show an approach to calculate these process emissions, so that a net environmental benefit can be calculated.

We’ll also discuss the importance of securely and credibly digitizing the data associated with a project. The methane that can be recovered during a pigging operation is determined by the line operating pressure and the geometric (a.k.a. water) volume of the associated launcher and receiver.

(Note that it is likely impractical to recover the small amount of methane that might be used to purge before launch due to the methane becoming mixed with air.)

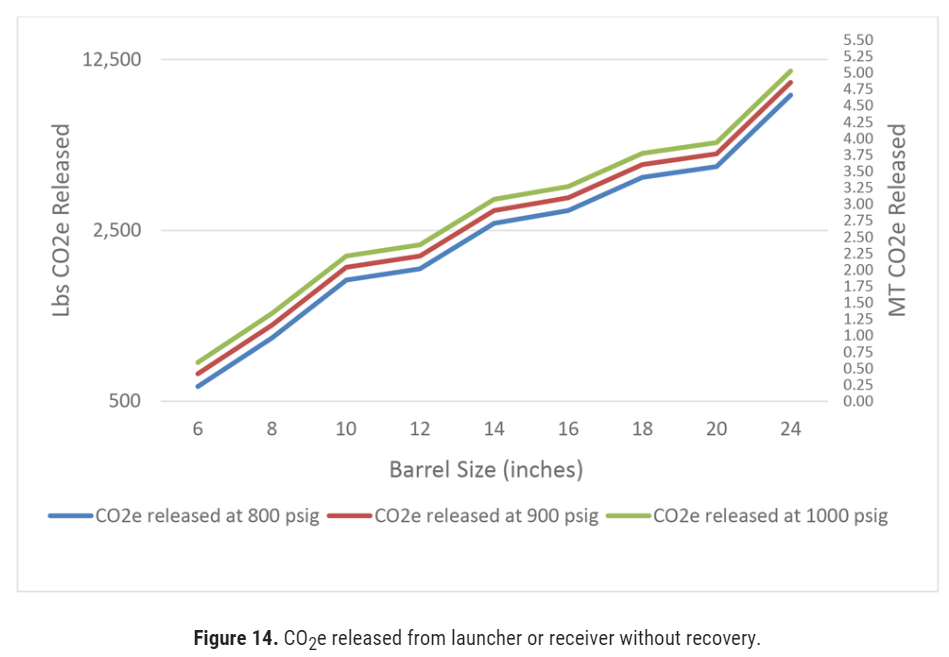

The volume of individual launchers/receivers will vary based on the design types used by individual pipeline operators. Based on information from one of our customers for the volumes of launchers and receivers of various barrel sizes, we calculated the volume of methane that would normally be released via venting to atmospheric pressure by a pig launch or receive operation.

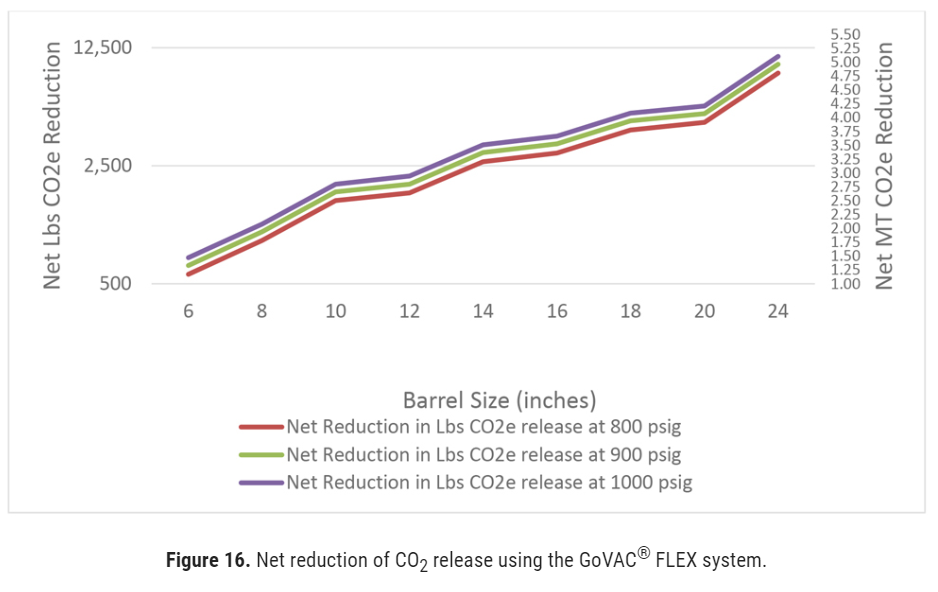

This is based on a function of barrel size and pipeline operating pressure, if no recovery process is used, Figure 14.

In calculating “avoided methane release,” one must account for the energy required (CO2 released) in the process used to avoid the release. In the case of using our GoVAC® FLEX system, some of the recovered methane is used to fuel the internal combustion engine that powers the compressor section.

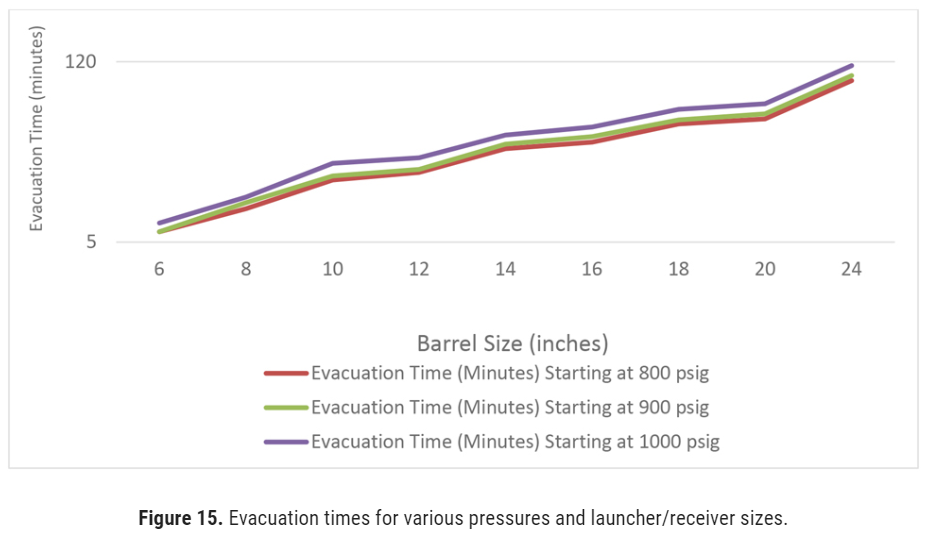

The engine computer control system logs fuel consumption, which can be used to calculate the net methane recovered. Due to the physics of performing an evacuation, the lower the final pressure, the longer an evacuation will take. When we perform an evacuation, we normally evacuate down to less than 1 psig. Figure 15 shows estimates of evacuation time for various barrel sizes and line pressures, based on such a low-pressure cut-off.

Based on these run times, we adjust the estimated CO2e emissions reduction due to methane consumption. These values are charted in the graph, Figure 16. These estimates are based on field data from previous projects that have seen an average of 8.56% consumption of the natural gas being evacuated.

While the unit is running, the data is streamed to the supervisorial control and data acquisition (SCADA) system that is hosted on the VPN. If there is no network connectivity, the data will automatically buffer on the local unit until it can connect and securely transfer the data.

Once the data is in the OBDVPN system, only the customer and Onboard Dynamics can access it. This ensures that the data used to generate the report represents the actual amounts that flowed through the system. This eliminates the possibility of a user making a mistake in recording data captured through the manual process of reading gauges.

The ability to have this data collection automated — even across multiple units — is a huge benefit to the pipeline operator and any associated auditing agency.

Summary

In the future, pipeline owners and operators will need to take ever more aggressive steps to reduce to an absolute minimum all methane releases into the atmosphere.

Fortunately, a variety of methane capture and recovery tools and services are becoming available to aid in dealing with this challenge. Matching the solution via a new tool or service requires understanding the characteristics of the project, whether a pigging operation or pipeline maintenance project, and matching those characteristics against the possible solutions.

Due to increasing regulatory oversight, it will be essential that every effort to mitigate methane release be fully documented, with a trail of secure data that can be audited. Without such validation and tracking, the best mitigation efforts could become an expense without commensurate payback.

References:

1 Environmental Protection Agency. (n.d.). Overview of Greenhouse Gases. EPA. Retrieved December 16, 2022, from https://www.epa.gov/ghgemissions/overview-greenhousegases

2 Ramseur, J. L. (2022, August 29). Inflation Reduction Act Methane Emissions Charge: In Brief. Congressional Research Service. Retrieved from https://crsreports.congress.gov/product/pdf/R/R47206#:%7E:text=The%20charge%20st arts%20at%20%24900,or%20tax%20on%20GHG%20emissions

3 Environmental Protection Agency. (n.d.). Subpart W – Petroleum and Natural Gas Systems. EPA. Retrieved Dec. 16, 2022, from https://www.epa.gov/ghgreporting/subpart-wpetroleum-and-natural-gas-systems

4 Ibid.

5 S.2299 - 116th congress (2019-2020): Pipes act of 2020. (n.d.). Retrieved December 17, 2022, from https://www.congress.gov/bill/116th-congress/senate-bill/2299

6 American Gas Association. (2022, November 30). Annual report of volumes, revenues, and customers by company (2002-2021). AGA. Retrieved December 16, 2022, from https://www.aga.org/research-policy/resource-library/annual-report-of-volumesrevenues-and-customers-by-company-2002-2020/

7 Lamar University Center for Midstream Management and Science . (n.d.). Top Ten issues facing midstream industry in 2022. Lamar.edu. Retrieved December 16, 2022, from https://www.lamar.edu/midstreamcenter/newsfeed/top-ten-issues-facing-midstreamindustry-in-2022.html

8 Ibid.

9 Environmental Protection Agency. (n.d.). 2020 Greenhouse Gas Emissions from Large Facilities. EPA Facility Level Information on Greenhouse Gases Tool. Retrieved from https://www.epa.gov/ 10 Ibid.

Editor’s note: This paper was first published at the 35th Pipeline Pigging and Integrity Management Conference, February 2023. Organized by Clarion Technical Conferences. Used with permission.

Comments