March 2024, Vol. 251, No. 3

Features

Protection in Renewal Biogas Systems for Increased Pipeline Reliability

Steve Biagiotti, Chief Engineer, Dynamic Risk

(P&GJ) — Biogas is a renewable fuel generated through the anaerobic fermentation of organic matter. Biogas is a mixture of gases, mainly methane and carbon dioxide, accompanied by trace elements dependent on the feedstock and production method.

The refining process can eliminate carbon dioxide, water vapor and other trace gases, transforming biogas into renewable natural gas (RNG) or biomethane, aligning it with natural gas industry standards. RNG can be injected into the existing natural gas grid and used interchangeably with conventional natural gas.

The principal challenges associated with biogas transportation involve the consistent control of non-methane constituents, notably water content and the maintenance of continuous flow. Instances of process upsets pose the risk of introducing water and corrosive constituents. During periods of intermittent or low flow rates, condensation or stagnation may occur, leading to internal corrosion.

Many times, RNG laterals connecting a biogas producer to injection points to a transmission pipeline are smaller diameter, relatively short lengths. These lines lack design features such as internal inspection launchers and receivers for inline inspection. Furthermore, their construction may involve 90-degree fittings, telescoping diameters, and other characteristics limiting the feasibility of routine internal cleaning.

Despite these challenges, methodologies exist to enable operators to anticipate locations prone to internal corrosion. Identifying such sites facilitates the implementation of corrosion monitoring programs, thereby addressing concerns related to internal corrosion in biogas transport systems.

Gascade partnered with Dynamic Risk to investigate the internal corrosion susceptibility of a biogas line in advance of a larger project targeting the prioritization of difficult-to-inspect pipelines.

About Gascade

Gascade Gastransport GmbH operates a gas pipeline network throughout Germany. The Kassel-based transmission system operator offers its customers modern and competitive transport services for natural gas and, in future, other gases in the heart of Europe via its own high-pressure pipeline network, which is about 2,300 miles (3,700 km) long.

Gascade, which wants to convert its pipeline network to the transport of hydrogen, is active in several onshore and offshore hydrogen projects, and has undertaken a comprehensive system-wide initiative to enact integrity management principles within its operations.

Recognizing the significance of evaluating challenging-to-assess pipelines, the organization has prioritized this aspect. In the year 2023, a notable project was initiated, marking the inaugural endeavor to scrutinize the threat posed by internal corrosion in a non-piggable biogas lateral through the application of modeling techniques.

Solution

A study leveraged the principles in NACE standard SP0206-2016, Dry Gas Internal Corrosion Direct Assessment (DG-ICDA), to identify susceptible locations along the pipeline where water might collect that could lead to internal metal loss.

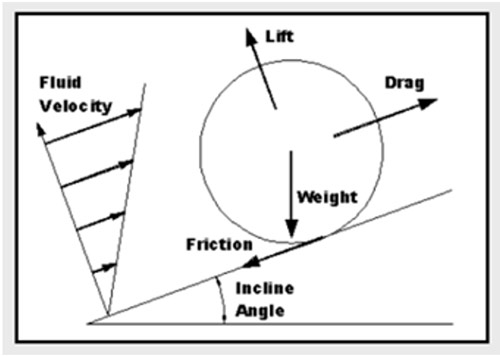

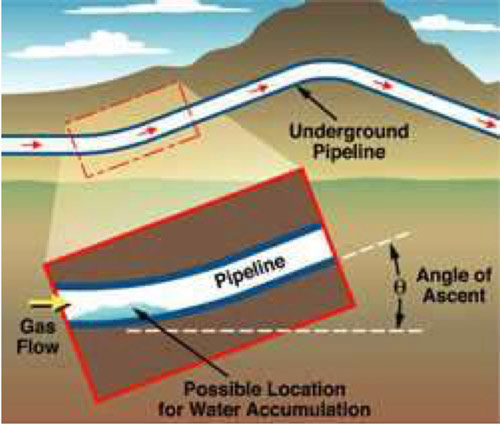

The process to identify susceptible internal metal loss locations involved developing the centerline inclination profile, then based on operating gas quality characteristics and flowrate properties, calculate a critical inclination angle beyond which liquid would become stagnant in the line (i.e., gas momentum could no longer push the fluid along the profile). Since the line historically has operated at several combinations of pressure and flowrate, multiple calculations and evaluations were performed.

The anticipation of critical inclination angles in this line is influenced by the comparatively low gas flow rates, yielding predictions with values below 2 degrees. During periods of zero biogas flow, the critical inclination angle is projected to be zero.

The elevation profile of the line exhibits a relatively flat trajectory in the initial few kilometers, subsequently descending toward the outlet. A subtle undulation, characterized by a slight rise and fall, is observed before reaching the termination point of the line.

The first critical inclination angle site occurred within the first 130 feet (40 meters) of the pipeline length, immediately downstream of the biogas production facility. Furthermore, since the line frequently has no flow, water normally restrained at the first critical inclination angle site will gravitate upstream back toward the pipe inlet during periods of no flow.

The analysis predicting internal corrosion indicates a substantial probability of water ingress becoming entrapped within the initial part of the system. Operational circumstances are conducive to internal metal loss occurring predominantly at the site characterized by the first critical angle.

However, during intervals of zero flow, the preferential metal loss site transitions to the low point of the pipeline. Given the rate-dependent nature of corrosion, both sites underwent thorough investigation.

Recommended corrective actions to reduce the potential for internal corrosion and further enhance pipeline reliability included:

- Target excavations and non-destructive evaluation (NDE) at the first two and last critical inclination sites

- Design modifications to support periodical cleaning pigs

- Additional filtration before gas inlet to minimize water ingress

“We are planning to inspect the pipeline at the suggested two to three locations by robotic internal MFL and visual inspection while the line is taken out of service due to re-routing activities in 2024,” said Stefan Klein, asset manager at Gascade. “I look forward to reviewing the results of the inspections.”

Project Outcome

The 2023 Internal Corrosion on Predictive Analysis project was completed just a few weeks after receiving the operational data. Subsequent discussions revealed a historical pattern of water accumulation and flow restriction, attributed to ice formation in proximity to the line's commencement.

Biogas can have unique gas qualities with the potential to increase the threat of internal corrosion. Monitoring and controlling inlet gas characteristics are engineering controls used to minimize this threat. However, inspection is needed to establish the condition of an asset per integrity management regulations. When complete asset inspection is not possible or practical, corrosion modeling with targeted inspections can be an effective alternative.

Benefits

- Rapid evaluation of a biogas pipeline for the threat of internal corrosion

- Targeted recommendations for validation digs

- Results can be integrated into risk assessment algorithms to enhance pipeline reliability based on an industry-established methodology.

- The avoidance of potential cost and safety concerns derived from circumventing unnecessary excavation and inspection procedures often outweigh the expenses associated with modeling.

This approach can be applied to a single pipeline or larger networks.

Comments