November 2018

Tech Notes

Transneft Diascan Comissions New Type of Inline Inspection Tool

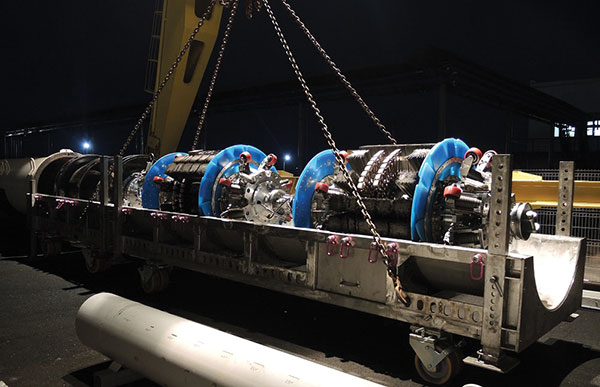

Transneft Diascan has developed, manufactured and commissioned a new type of inline inspection tool that can find peeling areas in the pipeline coating. The Moscow-based company said its new EMA-based defectoscope is the eighth tool type in its ILI portfolio.

The device is equipped with a measuring system that uses electromagnetic-acoustic transducers (EMATs). Its ultrasonic diagnostic method does not require the use of immersion fluid and is based on direct and inverse electromagnetic-acoustic transduction. This allows the new inspection tool to detect pipeline coating defects sized 100-by-100 mm and bigger.

Development of the device started in January 2015 and lasted until August 2018. During the preliminary and acceptance tests, the tool withstood temperatures from -40º С to 60º С and mechanical damage resistance. The inspection tool passed onsite tests at Transneft Diascan’s testing facility and at a section of Transneft Urals’ pipeline, the company said. P&GJ

Comments