September 2018, Vol. 245, No. 9

Tech Notes

Norwegian Driller's Subsea Robotics Include Pipe-Handling Systems

An offshore drilling company from Norway is using energy chains from igus to help provide a reliable power supply under extreme conditions for automated drilling operations on platforms.

Robotic Drilling Systems AS in Stavanger, Norway – a central city in the European oil industry – developed robots in an effort to fully automate drill floor operation of oil rigs. Oil platform drilling is one of the most dangerous occupations in the world, as workers must contend with high waves, storms with high winds, oil, mud, and rain. Drill pipes are driven from the uphole, unscrewed and then reassembled under heavy pressure.

The robotic systems must stand up against salt water, corrosion, mechanical stress and, frequently, extreme temperatures. In addition, the work processes on an oil rig are so complex that up to 100 axes need to be coordinated in the handling of the drill pipe. Energy, media and signals must be guided reliably to the grippers of the robot.

Core Component

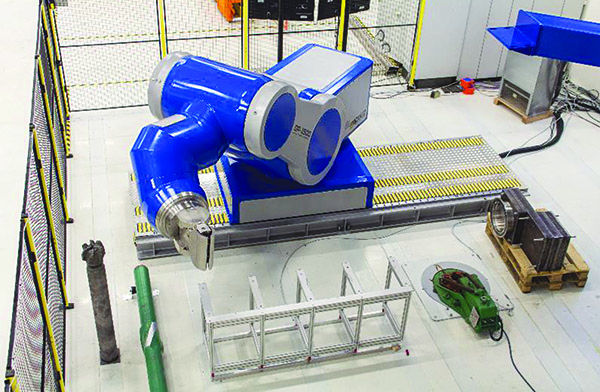

RDS has developed a family of robots to undertake subtasks of automated drilling. Its primary piece of equipment is a “drill floor” heavy-duty, six-axis robot with a load capacity of 1,500 kg, which is handled by a 3-meter robotic arm and a newly developed gripper.

The fully automated pipe handler takes out the segments from a storage system or from a conveyor on deck and supplies them to the robot. Another RDS robot system, “the electric roughneck,” and a pipe handling robot support the heavy-duty robot in handling and comprise the robot “stand.”

The systems work together to ensure the entire drilling process is carried out without human intervention. RDS claims the system operates up to 40% faster and saves between $10 million to $20 million annually.

The seventh axis of the drill floor robot is a heavy-duty linear system, upon which the entire robot moves. Engineers were challenged to provide moving energy and signal supply in extremely confined spaces. The axis also needs high explosion protection.

For the linear movement of the seventh axis, the energy supply could be delivered with lightweight energy chains made of plastic. The e-chains have proven themselves in numerous similar applications and enable the simultaneous guiding of cables for energy, data and media. The more difficult challenge for design engineers was supplying the rotational axis of the robot base with energy and signal supply.

Rotary Module

A rotary module by igus solves the energy and signal supply dilemma. The module is an energy chain that is side mounted and operates with a reverse bending radius (RBR). This means that the chain links can move in both directions, unlike conventional linear travels. The cables and hoses are securely guided in the chain with locking separators, and the chain operates in a round guide trough.

The rotary module is integrated into the robot housing. The design required complex engineering due to the limited space within the housing. The Project Engineering division at igus designed the feature.

The energy chains are delivered in Stavanger assembled as “ready chain” systems, including connectors, which helps ease installation. It also ensures that all ports and connectors meet the special requirements of electrical explosion and protection. The maintenance-free plastic energy chains also offer superior corrosion resistance.

Vertical Movement

Components from igus are used in the other automation units of the unmanned oil drilling process. Energy chains are used on the “electric roughneck” and the “pipe handler.” They are installed on the masts, which are the vertical axes of handling systems where the “stand” is taken from the storage and supplied to the central robot.

Freedom from maintenance, resistance to saltwater, and withstanding mechanical stresses as well as explosion-proof and offshore approvals are critical in the selection of the components used in the robots.

“It is important for us to purchase components for the robot from one source and get them ready for installation,’’ said Jimmy Bostrom, chief operating officer at Robotic Drilling Systems. “The systems should also be as maintenance-free as possible.”

The robot system developed by RDS for oil drilling is suitable for installation on new rigs and retrofits. It also establishes new guidelines for assessing the profitability of exploration projects, an important factor given the price of oil.

After extensive testing, a first practical installation was put into operation in September 2015 on a rig in Norway. The entire oil drilling industry is monitoring the project, which makes the work on oil platforms faster, less expensive and most importantly, safe. P&GJ

Comments