July 2019, Vol. 246, No. 7

Features

SwRI Improves Structural Monitoring of Aging Pipelines with Transducers

By Sergey Vinogradov and Jay Fisher, Southwest Research Institute

Maintenance of aging pipelines, especially ones that are insulated and/or buried, is a major challenge, due to limited access for application of conventional nondestructive evaluation (NDE) techniques. Even when access is available, financial and time constraints mean that conventional NDE is often carried out on a sampling basis, which makes it less reliable than full coverage inspection.

Long-range guided wave testing (GWT), a potential solution to this problem, has been commercially available for conducting inspections for about 20 years. This technology, which uses low-frequency ultrasonic waves that are guided by the structure they are propagated in, showed potential to inspect long (100-plus meters) of structure from a single sensor location.1-3

Southwest Research Institute developed GWT transducers using magnetostrictive transduction in 2000. Magnetostriction is the property of ferromagnetic materials that cause them to change their shape when a magnetic field is applied. Thus, a time-varying magnetic field can cause the ferromagnetic material to generate ultrasonic waves. Improved versions of magnetostrictive sensors were subsequently developed for use as low-cost permanently mounted sensors to support structural health monitoring (SHM).4

A novel magnetostrictive transducer (MsT) using a reversed Wiedemann effect was invented in 2008.5,6 These transducers exhibit a number of improved features compared with the original sensors, including: (1) large, uniform, permanent bias magnetic fields provided by the use of small rare earth permanent magnets, (2) stronger signals provided by more efficient electric coil arrangements, and (3) the ability to generate both transverse and longitudinal waves. MsTs can be designed for pipes ranging from a few millimeters to several meters in diameter.

The MsTs have an extremely simple design that provides high service reliability and long life over an extreme range of temperatures. The major component of the sensor is ferromagnetic strip material. The strip is wrapped by a solenoidal winding that is pulsed to create a time-varying magnetic field in the strip.

The third component is a belt of low-profile rare earth permanent magnets that provide the magnetic bias field needed to optimize the magnetostrictive generation of guided waves. Figure 1(a) shows the basic MsT collar used in the design. Due to the use of rugged components and an absence of soldered joints, the MsT collar probe can be made very reliable.

The recent development of GWT probes designed for permanent installation on pipes has allowed SHM of long lengths of pipeline without the need for periodic access to the pipe. The technology involves permanent installation of MsT probes on the pipeline, establishing baseline data, periodically collecting data online, and tracking any condition changes by comparing the baseline and periodically collected data.

Figure 1(b) shows the results of long-term monitoring of a 4-inch schedule 40 pipe. The black trace shows data collected initially at a 32 kHz center frequency in 2011. The green trace shows data collected in 2018. As can be noted in this figure, clusters of generalized pitting corrosion developed on the pipe OD produced noticeable indications on the green trace. Also, a 9-mm diameter drilled hole introduced at a distance 3.8 meters from the probe produced a high amplitude indication.

Overall, the probe produced very steady signal amplitudes over the seven-year span. In addition to simple waveform comparison, a baseline stretching-and-subtraction algorithm is utilized to eliminate the indications related to pre-existing conditions such as weld and geometry indications as well as multiple reflections. This step helps to identify pipe condition changes in the areas such as welds or pipe supports, and it compensates for changes in pipe temperature.

MsT probes produce high signal amplitudes over a wide frequency range (e.g., 10–90 kHz) while providing for control of the propagation direction.

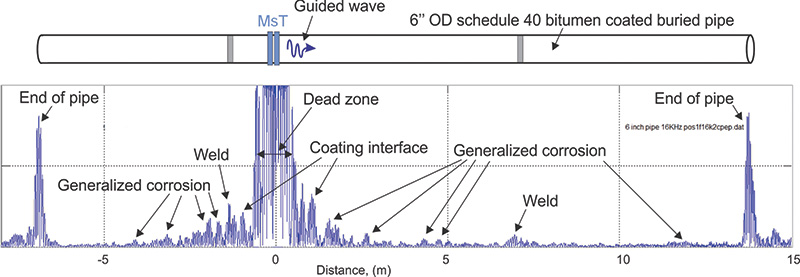

A collar MsT probe is mounted on a 6-inch schedule 40 bitumen-coated, buried pipe. An example of data acquired using this MsT.

The guided wave can be directed selectively in either direction away from the probe. In this case, approximately 14 meters of coverage in each direction was accomplished using a 16 kHz center frequency. Compared to above-ground pipes, the bitumen-coated and buried pipe is more challenging for inspection and analysis due to the higher attenuation and indication from the coating. Indications relevant to coating damage need to be sorted out form indications relevant to metal loss and indications relevant to geometry.

Current MsT transducers offer the next level of signal strength and reproducibility. The circular, hard-shell MsT can be produced in segments, allowing the structure to be inspected at different circumferential positions, providing more thorough inspections and easing data analysis. In addition, MsTs can be produced with the capability to generate either transverse (torsional) waves or longitudinal waves, with the flip of a built-in switch. Longitudinal waves provide longer-range coverage in pipe buried in sand, while transverse waves are better for inspecting pipes filled with fluids because they do not propagate in the fluids. P&GJ

Authors: Sergey Vinogradov is a staff engineer in the Structural Engineering Department of Southwest Research Institute. He has developed guided wave sensors for over 20 years and has eight patents in this area. This past spring, the American Society for Nondestructive Testing (ASNT) presented him with the 2018 Research Recognition for Innovation Award for the MsT sensor. The award recognizes highly distinguished breakthroughs in nondestructive evaluation and testing research.

Jay Fisher is a program director in the Mechanical Engineering Division of Southwest Research Institute. His nondestructive evaluation expertise has led to developments in flaw detection and material characterization using an array of techniques, including ultrasonics, eddy current, electromagnetic acoustic transducer, and magnetostrictive sensor inspection. He also serves as a reviewer for the American Institute of Physics Review of Scientific Instruments and the IEEE Sensors Journal.

References:

1 Lowe M. and Cawley P., “Long range guided wave inspection usage – current commercial capabilities and research directions,” Imperial College London, Tech. Rep.

2 Rose J.L., “A Baseline and Vision of Ultrasonic Guided Wave Inspection Potential,” Journal of Pressure Vessel Technology, Vol. 124, pp. 273-282, 2002.

3 Mudge P.J., “Field application of the Teletest long-range ultrasonic testing technique,” Insight, 2001.

4 Kwun H. and Light G., “Magnetostrictive Sensor Technology Proven in Process Applications,” Oil and Gas Journal, Vol. 98.21, 2000.

5 Vinogradov S., “Magnetostrictive Transducer for Torsional Mode Guided Wave in Pipes and Plates,” Materials Evaluation, Vol. 67, N 3, 2009, pp. 333–341.

6 Vinogradov S., Cobb A., Fisher J., “New Magnetostrictive Transducer Designs for Emerging Application Areas of NDE,” Materials 11(5), May 2018, DOI: 10.3390/ma11050755.

Comments