March 2020, Vol. 247, No. 3

Tech Notes

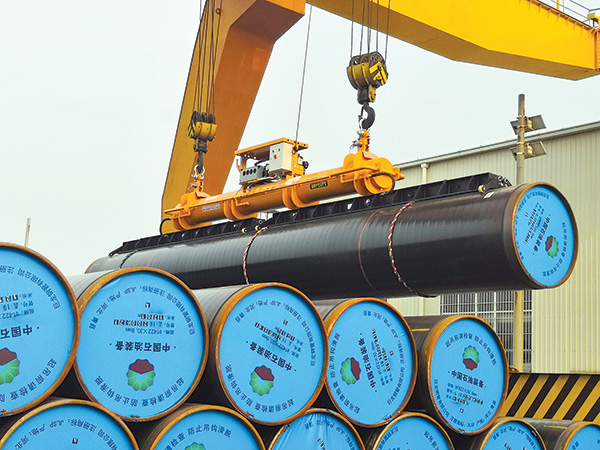

Vacuum Lifting More Common Among Pipehandlers

Commonly, pipes are stacked several meters high in the shape of a pyramid, meaning that in order to attach lifting equipment, someone must climb the stack. This can be a dangerous situation; however, lifting by vacuum offers a solution.

Vacuum-lifting devices are increasingly common in the oil and gas industry. Among the equipment’s chief advantages is that no one has to be near the pipes during any portion of the handling process.

The vacuum-lifting device is controlled by the crane operator from a safe distance, with the lifting device lowered onto the pipe. Through a push of a button, the operator activates the vacuum, securing the pipe safely to the lifting device. Then, the pipe can be lifted and transported.

“Unlike conventional lifting methods, a vacuum-lifting device continuously monitors the safety status,” according to an Aerolift Industries B.V. designer. “If the vacuum level drops below 80%, the lifter emits a clear, visible and audible signal, urging the operator to lower the pipe. But still, the pipe will stay attached safely for several minutes.”

Also, if there is a power failure, the pipe stays attached for minutes, leaving enough time to take corrective measures.

Additionally, vacuum lifting does not require spacers or stoppers, and allows for the optimum use of space and faster handling.

In cases in which the coated pipes are not airtight, Aerolift designed mechanical pipe-lifting devices. These are designed to offer the same advantages as a vacuum pipe lifter. There are also solutions for lifting from plate to pipe.

The vacuum lifter can be provided with exchangeable suction pads that enable the same vacuum lifter to handle both plates and pipes. Exchangeable suction pads can also be used to handle pipes of varying diameters.

Comments