May 2024, Vol. 251, No. 5

What's New

What's New May 2024

Process Vision

Process Vision launched of its latest LineVu process camera, equipped with 24/7 automatic alarms for contamination detection and bolstered by thermal performance that ranges from 30°C (86°F) to 55°C (131°F), with power delivered efficiently over Ethernet (POE+).

The camera provides engineers and operators with a high-resolution, high frame-rate camera. The camera body can be attached to the pipeline using a flanged (3-inch #900 RTJ) connection, with the option for threaded (1-inch NPT) or alternative flange connections via adaptors.

Designed to mount easily on high-pressure gas pipelines, engineers and operators can now investigate liquid carryover events with a swift method for information gathering, allowing prompt decision-making options. www.processvision.com

PipeWizard

The PipeWizard iX automated ultrasonic testing (AUT) system has been optimized to redefine pipeline weld joint assessments. Building upon the ruggedness and reliability of its predecessor, the system’s redesign improves ease of operation and adaptability.

The update includes more powerful and versatile data acquisition technology, increasing the efficiency and reliability of phased array (PA) inspections of circumferential pipeline welds. It also has a lighter, easy-swivel umbilical, an optimized clamping mechanism and more compact scanner with integrated data acquisition instrument.

The system offers additional umbilical length options, quick-latching connectors and configurable probe modules, capable of holding up to 12 probes. PipeWizard iX’s companion software offers sophisticated tools, including embedded ES BeamTool software, a calibration block designer and assisted analysis. www.EvidentScientific.com

Decom

Decom Engineering has developed its largest Chopsaw in response to client demand for larger sized subsea pipe-cutting capability. The C1-46 cuts tubulars and other materials up to 46 inches, and its innovative design is able to cut a wide range of materials, including inconel alloys, duplex and concrete.

It can be operated in water depths of up to 2,000 meters and is currently deployed on its first project on behalf of a global energy company on a U.K. North Sea workscope, which involves cutting large surface laid pipelines (36-inch) with 57-mm concrete coating, along with other large pipelines.

With the ability to cut in any orientation, the C1-46 is capable of multiple cuts per blade (20-100), resulting in large cost savings and increased efficiency. Blade changes are efficient, safe and the Chopsaw can be supplied set up in a number of configurations and settings to suit project requirements. www.decomengineering.co.uk

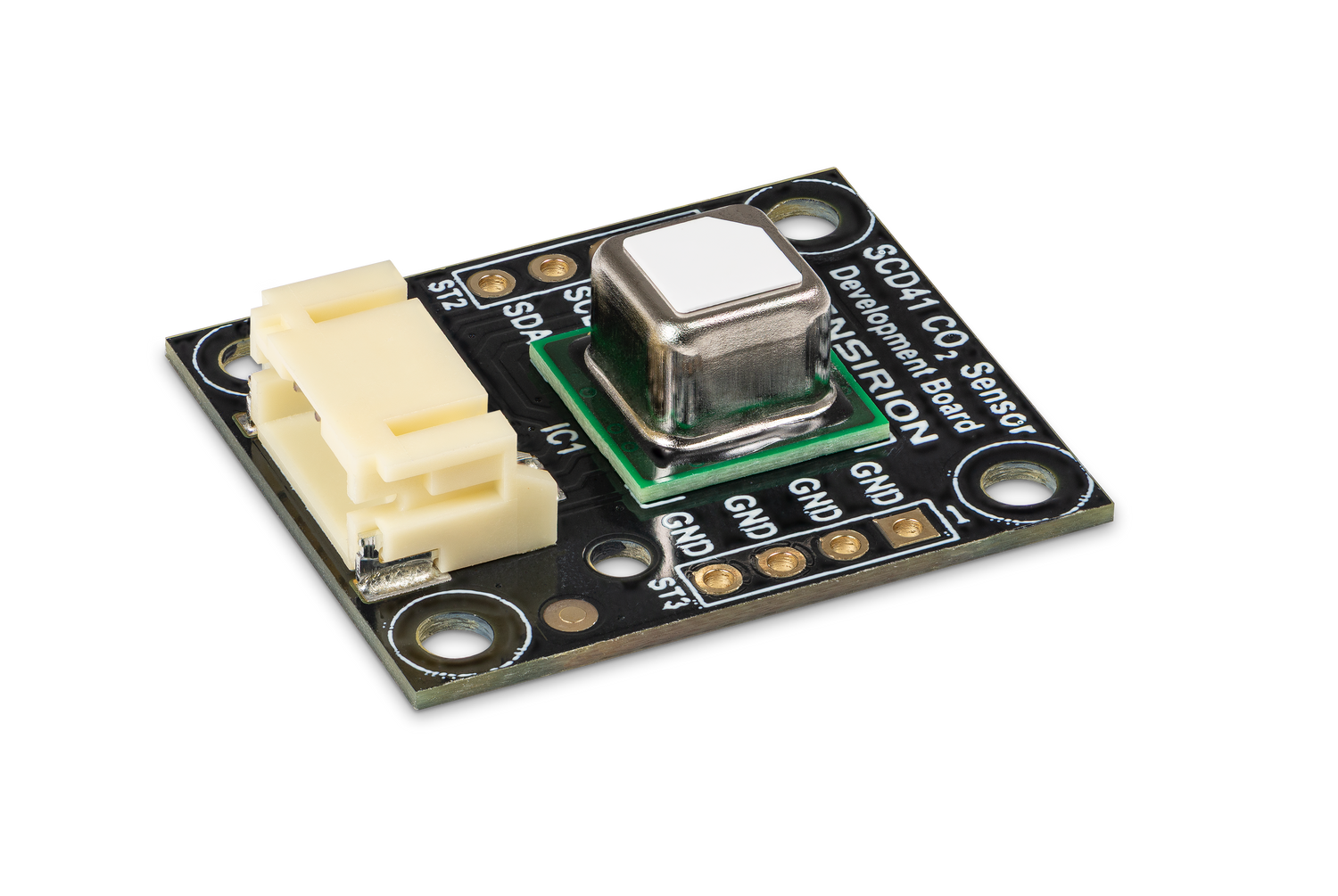

Sensirion

Sensirion offered its next-generation miniature CO2 sensor series, the SCD4x. The device is built on the photo-acoustic sensing principle and the patented PASens and CMOSens Technology enables the small sensor size to combine with high performance.

The integrated humidity and temperature sensor enable on-chip signal compensation and additional RH and T outputs. Also, the large supply voltage range (2.4 V-5.5 V), and adjustable power consumption make the SCD4x increases savings.

The kit contains a four-pin jumper wire cable that enables fast prototyping, through integration into existing platforms like Arduino and Raspberry Pi. www.sensirion.com/scd4x

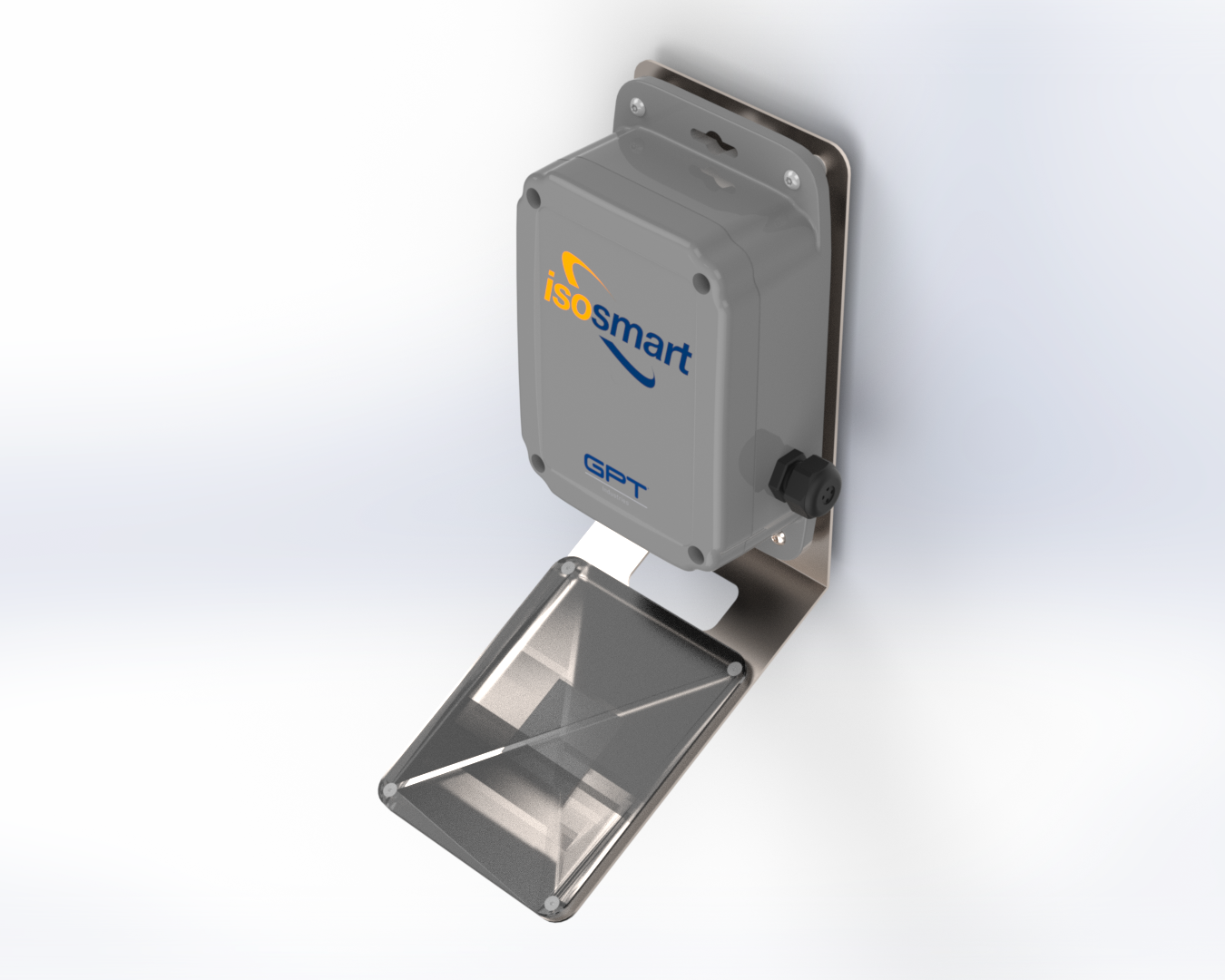

GPT Industries

GPT Industries launched its remote pipeline monitoring system, Iso-Smart, an all-in-one solution developed based on customer feedback for checking cathodic protection (on and instant off potentials), isolation, bond currents, AC vs. DC on the line, and more from remote locations.

It incorporates True RMS technology to provide reliable data, helping pipeline owners make informed decisions and comply with DOT pipeline integrity regulations. Key features of Iso-Smart enabling this remote monitoring capability include cellular LTE connectivity, rechargeable battery for multi-year operation, a compact design and an intuitive dashboard.

The Iso-Smart launch culminates years of R&D and extensive customer input to meet expanding industry needs. www.gptindustries.com

OleumTech

OleumTech offers its electromagnetic flow meter as part of its H Series hardwired process instrumentation line.

The OleumTech HEFM Magnetic Flow Meter offers polytetrafluoroethylene (PTFE) lining material, a backlit local display interface and various self-diagnostic features for managing critical device health. The HEFM flow meters can be custom ordered using a variety of line sizes, materials and power options to fit the needs of OleumTech end users.

Highlights include independent measurement of fluid density, viscosity, temperature, pressure and conductivity; two measuring points inside the meter with no moving parts; reference accuracy of ±0.2% of reading; output signal options of RS485 Modbus/4-20 mA/2-8 kHz pulse output; and a backlit liquid crystal display (LCD) with integral push-button interface. www.oleumtech.com

Endress+Hauser

Endress+Hauser offers the Prosonic Flow P 500 measuring system, a device that requires only minimal straight inlet runs and can be installed directly onto the exterior of the pipe, so there is no need to interrupt operations.

In contrast to mechanical meters with high maintenance requirements, ultrasonic flowmeters have no moving parts.

It can be mounted on a wide variety of pipeline types, including steel or cast-iron and plastic. A special, maintenance-free contact foil (coupling pad) provides optimum sound transmission between the sensor surface and the pipe.

Depending on the line size, fluid, and pipe material, the sensors are delivered with different ultrasonic frequencies (0.3, 0.5, 1, 2, or 5 MHz) to provide maximum signal quality, and thus a high level of accuracy and repeatability. www.endress.com

Comments