February 2012, Vol. 239 No. 2

Features

Virtual Reality 3D Training For Pipeline Employees

Companies in the midstream energy industry are under pressure from all directions. While operating efficiently, it is mandatory that they comply with increasingly stringent health, safety and environmental regulations.

New facilities must be brought online quickly, an aging infrastructure must be upgraded and modernized and a retiring workforce, with the potential loss of know-how and experience, must be replaced – all with minimal service interruptions.

The oil and gas segment in particular has significant challenges. Refineries, offshore rigs, and other processing plants are some of the world’s largest, most complex facilities. Many upgrade, refurbishment and maintenance projects involve hundreds of workers who must be thoroughly trained – especially in safety-related operations such as handling fires, toxic chemicals, high-pressure leaks and other emergency incidents. Scheduling requires precise choreography to ensure each step occurs on time and in proper sequence.

Many companies typically have mandatory training for their workers and subcontractors a few weeks a year. Challenges to meet training requirements are compounded at offshore sites accessible only by helicopter or boat. Crews generally are replaced every six weeks on offshore drilling platforms, where on-site training is expensive and disruptive to routine work. Conducting training exercises on-site using actual equipment presents a higher risk of damage to valuable equipment and the crew’s safety, especially subcontractors and new personnel who are unfamiliar with the site. On the other hand, off-site mock-ups are expensive to construct and often do not realistically replicate real-world scenarios.

3D Simulation

A growing number of companies in the pipeline and gas distribution industries are addressing training challenges through the use of 3D virtual planning, simulation and visualization technologies. Such systems allow people to plan and schedule operational procedures, train workers and meet health and safety requirements by interacting with a computer-simulated 3D environment, including cranes, plant assets and workers to determine the best process to minimize project delays and mitigate project execution risk.

By studying procedures in this virtual world, engineers, planners, safety experts and workers can identify problems, explore options and determine the best remedy without disrupting actual plant operations. With lifelike 3D models, simulations and visualizations, planners can test their project plans virtually, and workers can see precisely what they need to do before they attempt it on the job. In this manner, optimal procedures and scheduling of operations can be worked out before projects are started in the plant or along the pipeline and workers can be safely trained off-site.

Typically, digital models are created from a combination of plant drawings, CAD geometry, 3D master models of the plant and laser scans of the facilities. Such digital models are highly detailed and significantly more accurate than physical mock-ups which, in most cases, are no more than rough approximations. Digital models also can be enhanced to incorporate representations of equipment such as cranes and the movement of such equipment in relation to interaction with the human workers and surrounding environment. In addition, the inclusion of physics representations can be used to simulate the realistic action of equipment such as the resistive force workers would encounter in turning a valve. All of this contributes to a virtual environment that looks and behaves realistically.

Virtual Ergonomics

Pipeline operators and constructors are urged to leverage virtual ergonomics to eliminate the need for physical mockups and ensure health and safety requirements. These simulations also can include lifelike models of humans or manikins for a wide range of virtual ergonomics or human factors studies. These 3D manikins are more sophisticated than the commonly known human avatars used in Virtual Reality (VR) or gaming systems. These manikins are built using anthropometric specifications for male and female (name, gender, weight, height, etc.).

Manikins possess fully articulated hand, spine, shoulder, and neck models to accurately reproduce natural movement such as reaching, grasping, walking, and lifting. This allows the choreography of multiple workers working in tight spaces because biomechanics tools can be used to examine worker posture, comfort, safety, strength, fatigue and efficiency in performing required tasks.

Virtual ergonomics simulations can be validated against ergonomic requirements for compliance with federal Occupational Safety and Health Administration (OSHA) and Quality Health and Safety Environment (QHSE) regulations. In this manner, operations and maintenance procedures can be thoroughly analyzed to ensure they are safe for workers, protect the public from potential hazards and lower the risks of damaging expensive equipment. Human factor studies are also useful in evaluating equipment layouts and accessibility, plant workflow, lifting requirements and more.

Operators can plan O&M procedures with 3D simulation-based systems. Planning for operations and maintenance procedures in the pipeline and gas distribution industries encompasses a wide range of diverse tasks. Major pieces of heavy equipment such as generators, coolers, valves and piping must be installed, replaced, inspected and repaired. Operational tasks such as crane operation and valve actuation must be performed. Complex sequences of actions must be completed quickly and flawlessly.

The traditional ways of planning rely on the experience of the workers and subcontractors to execute the required maintenance tasks. But supporting 2D drawings and historical information are often inaccurate and outdated leading to miscommunications among the various project teams during the actual execution, resulting in expensive delays to the project, unsafe working conditions and costly project rework.

3D simulation-based systems for planning scheduled maintenance or new operational procedures provide an effective way for engineers to develop precise and detailed plans to execute work “right the first time” by studying various scenarios and performing what-if evaluations well before tasks are attempted with actual equipment.

For example, simulations can be performed to determine optimal paths for removing or installing equipment, minimizing interferences and identifying areas where structures or piping must be removed to clear the path of obstacles. Software developed specifically for such studies provides visual alert notices during the simulation and detailed clash reports listing all interferences. Engineers use this information to study and modify motion paths until a feasible plan is determined. Likewise, the kinematic motion of cranes, robotics or other equipment can be accurately simulated to check that the devices can perform the required operations. In addition, a company’s valuable know-how and intellectual property can be captured and retained in the 3D environment for future project planning.

Operators can maximize workflow and utilization of resources with detailed planning and coordinated work schedules. Properly executing planned O&M procedures is the critical function of scheduling – that is, the development of timelines, asset utilization resource allocations and personnel requirements. Scheduling takes this into account as a basis for construction and process planning, operations and maintenance tasks, and personnel assignments.

Effective scheduling requires output on individual task durations, equipment needs, and resource requirements. Leverage existing schedule and resource information created in standard applications (such as Primavera or MS Project) by importing it to the project’s 3D work breakdown structure (WBS), which combines information on timelines, activities and resources. Linking the schedule to the 3D WBS and the 3D process simulation model creates an animated, time-based 4D representation (3D plus the variable of time) that enables users to more easily visualize and understand operations and timelines.

In this way, scenarios can be rearranged to more readily spot conflicts, find an optimal critical path and develop an optimized schedule taking all interrelated operations and processes into account. This approach is far better than conventional static, paper-based scheduling schemes that are difficult to interpret and hard to relate to actual plant operations. Cost as a fifth dimension can be added to the simulation.

Virtual Training

Virtual training can promote safety, reduce the risk of mistakes and eliminate work disruptions. After optimal maintenance scenarios and related work schedules are developed, companies can save and capitalize on this captured knowledge. They can replay the simulations as needed, easily making changes to adapt to different conditions, and leveraging the information throughout the plant’s entire lifecycle.

Reusing and leveraging the operations and maintenance planning simulations for virtual training purposes is of particular value. Planning and training can be done separately, but tightly integrating these two functions within a single-platform vendor environment is the most efficient approach for creating training scenarios and ensuring they reflect current operations and maintenance planning procedures. Virtual reality guides workers through procedures interactively, indicating when they’re wrong and showing them correct sequences of operations.

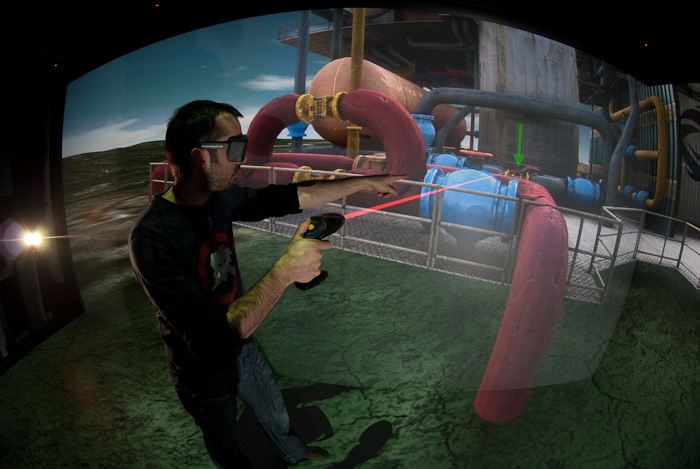

Virtual Reality (VR) training systems create a lifelike, immersive environment that adds another dynamic dimension to 3D simulations. VR technologies enable users to interact with computer-simulated equipment and surroundings in lifelike realism. Most of these applications are used in worker training where some of the most advanced systems use 360-degree wrap-around theaters with photorealistic imagery viewed with stereoscopic glasses. Multiple speakers generate high-fidelity sound effects to familiarize workers with the harsh and sometimes subtle sounds found on the actual jobsite.

Head-mounted goggles track head and eye movements, allowing the system to recognize where users are focusing their attention in the overall scene. In this way, workers can be trained off-site using VR without disrupting normal work routines or exposing them to the hazards of performing an untried or unfamiliar task in a real-life setting.

In any of these systems, different maintenance and operations scenarios can be easily performed without workers being on the actual plant/rig site. Workers can become familiar with the plant or pipeline layout, equipment operation, walking paths and evacuation routes and memorize the location of safety devices. Workers can learn specific operations and maintenance procedures such as plant start-up and shut-down, equipment maintenance, inspection and replacement so they are immediately productive. A report issued at the end of virtual reality training indicates which tasks were successfully performed and which mistakes were made so employees can be “coached up” on individual skills while the company is able to create regulatory documentation.

Conclusion

Companies in the energy industry are leveraging simulation technology to ensure workers are well-prepared with the skills and knowledge necessary to work safely in an unforgiving environment. These organizations are increasing productivity and lowering costs by better planning operations and maintenance procedures, maximizing workflow and utilization of resources with detailed and coordinated scheduling and making plants safer and more efficient with comprehensive simulation-based training. The business value of these applications is immense in reducing the costs of nonproductive time measured in hundreds of millions of dollars annually and avoiding the billions of dollars lost every year due to operating inefficiencies.

Authors

Harry Daglas is vice president Energy and Shipbuilding, PLM (product life-cycle management) at Dassault Systemes, which is a vendor of PLM software in 11 industries. Contact him via Tim Morin, 617-986-5010, tim@ famapr.com.

Garth Coleman is the director of Channel Marketing for 3DVIA at Dassault Systèmes. He manages all aspects of product marketing for 3DVIA Composer, manages the North American pre-sales support team, and is responsible for maintaining leadership in 3D applications which demonstrate life-like experiences.

Julie Charland has been involved in the field of ergonomics since 1994 and is now managing the WW Industry Solutions and Consulting team for Virtual Ergonomics. Her master’s degree in kinanthropology (ergonomics/biomechanics) has allowed her to specialize in applied ergonomics research.

Karun Chakravarthy is DELMIA Energy Industry Solutions Leader for Dassault Systemes where he helps define company strategy for all segments of the energy industry and assists customers in deploying project life-cycle management solutions.

Comments